Test head

A test head and double head technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of complex structure, many connection links, and high cost of detection connectors, and achieve simple structure, fewer connection links, and small errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

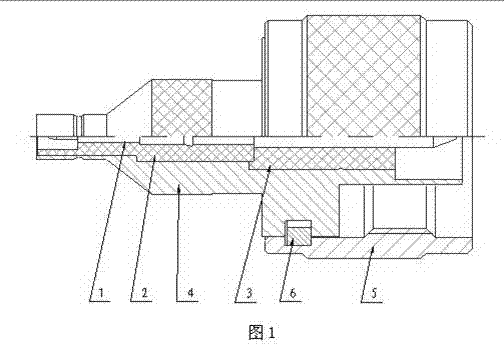

[0010] one This kind of test head includes a shell 4, two insulators (2, 3) are arranged in the inner cavity of the shell 4, there is a concentric through hole in the middle of the two insulators, a double-ended pin 1 is arranged in the through hole, and one end of the pin is connected to the Test the connection of the RF coaxial connector, and the other end is connected with the testing equipment; the outer wall of the shell 4 is covered with a screw sleeve 5, the outer wall of the shell 4 is provided with an annular groove, and the inner wall of the corresponding screw sleeve 5 is provided with an annular groove. A snap ring 6 is arranged between the grooves.

[0011] Such as figure 1 Shown: a test head, including: pin 1, insulator 2, insulator 3, shell 4, screw sleeve 5, snap ring 6 according to the size of the outer diameter of both ends of the pin 1, press them into the insulator 2 in turn, the insulator 3. There is a knurling or barb in the middle of the thinner end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com