Plastic and metal mixed front frame and liquid crystal module

A liquid crystal module and hybrid technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problem that the static electricity of the cost liquid crystal panel cannot be released, and achieve the effect of reducing weight, reducing production cost, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

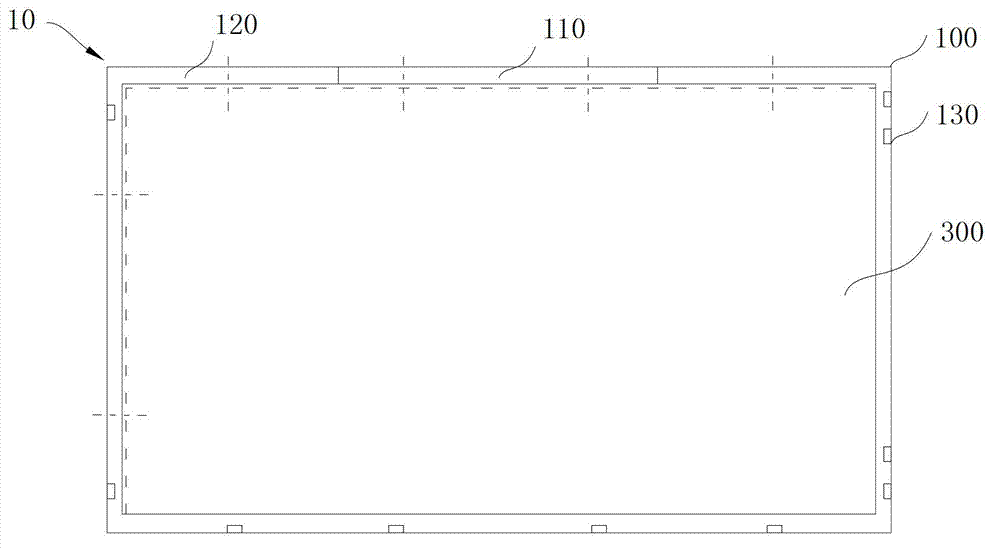

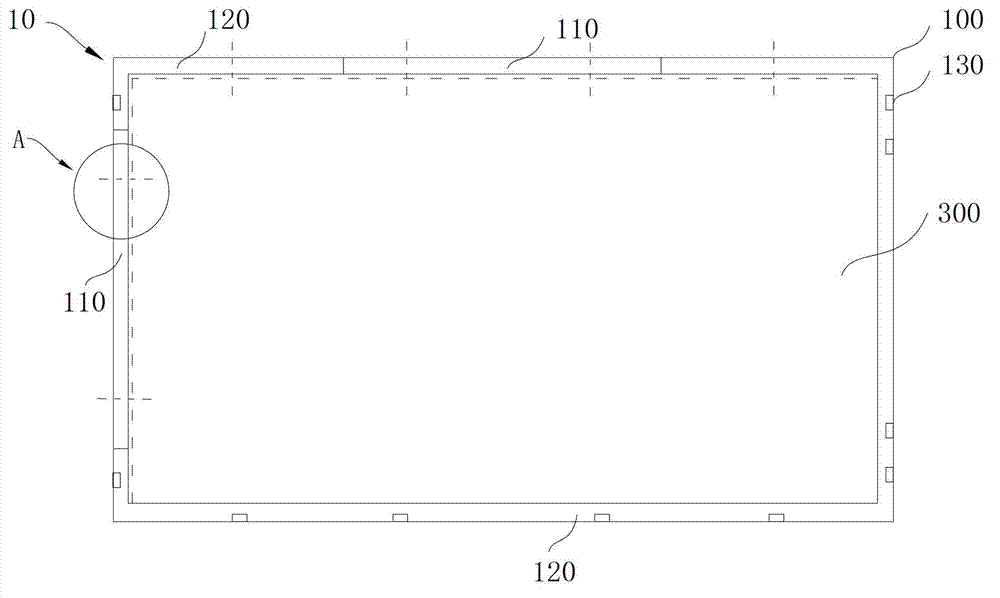

[0023] Such as Figure 4 As shown, the liquid crystal module 10 described in this embodiment includes, from the outside to the inside, a hybrid front frame 100 and a plastic frame 200 that are mutually matched and fixed, and are clamped between the hybrid front frame 100 and the plastic frame 200. Between the liquid crystal panel 300 and the backplane 400, wherein the backplane 400 is made of conductive materials such as metal.

[0024] Such as Figure 2 to Figure 5 As shown, the hybrid front frame 100 is composed of metal parts 110 and plastic parts 120 connected, wherein the hybrid front frame 100 only adopts at least one metal part 110 at the position where the chip-on-chip film 310 is arranged, and the other front frames 100 are correspondingly The plastic part 120 made of plastic material is adopted. The COF 310 is arranged along the upper side or the left side of the liquid crystal panel 300. Specifically, four source COFs (SoucreCOF) and two gate COFs (GateCOF) are re...

Embodiment 2

[0029] Such as Figure 6 As shown, the difference between it and Embodiment 1 is that compared with the hybrid front frame in Embodiment 1 which is a split front frame, the hybrid front frame 100 in this embodiment is an integrated front frame. After the metal part 110 is produced, it is placed in a plastic model, and the plastic injection molding process is adopted to make the metal part 110 and the plastic part 120 form an integrated front frame. Post-assembly process improves production efficiency.

[0030] To sum up, according to the actual application, a hybrid front frame design is adopted, and the components arranged in different positions are made of metal or plastic materials to form the hybrid front frame, that is, the front frame at the corresponding part of at least one COF Use metal parts, and then electrically connect the metal parts and the backplane of conductive material through conductive parts, so as to effectively discharge the static electricity of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com