Method for increasing responding speed of phase only liquid crystal on silicon device

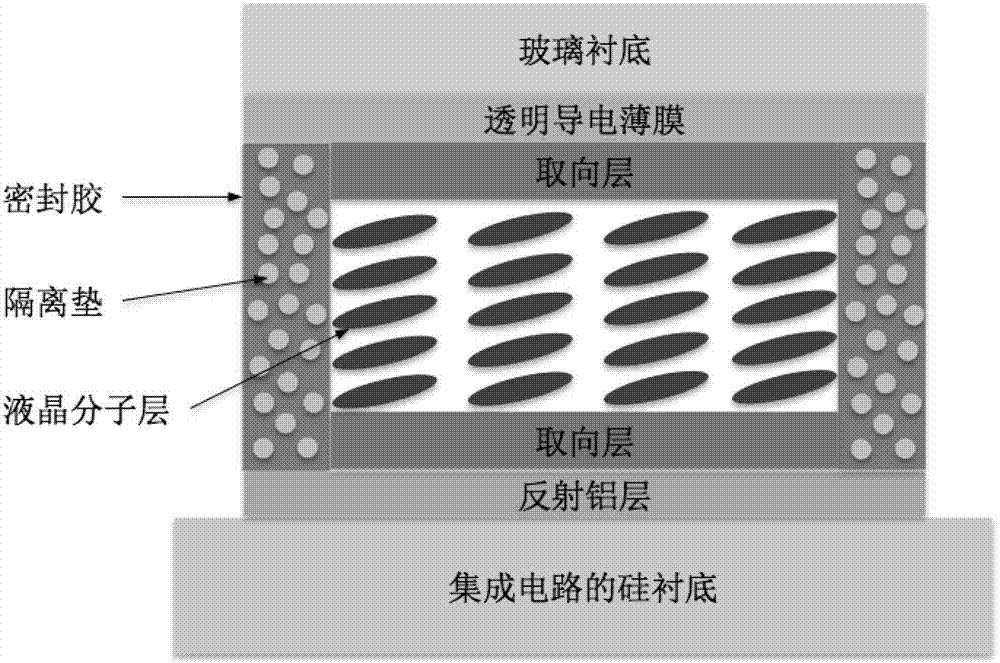

A silicon-based liquid crystal, response speed technology, applied in static indicators and other directions, can solve the problem of slow response speed of phase-controlled silicon-based liquid crystal devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

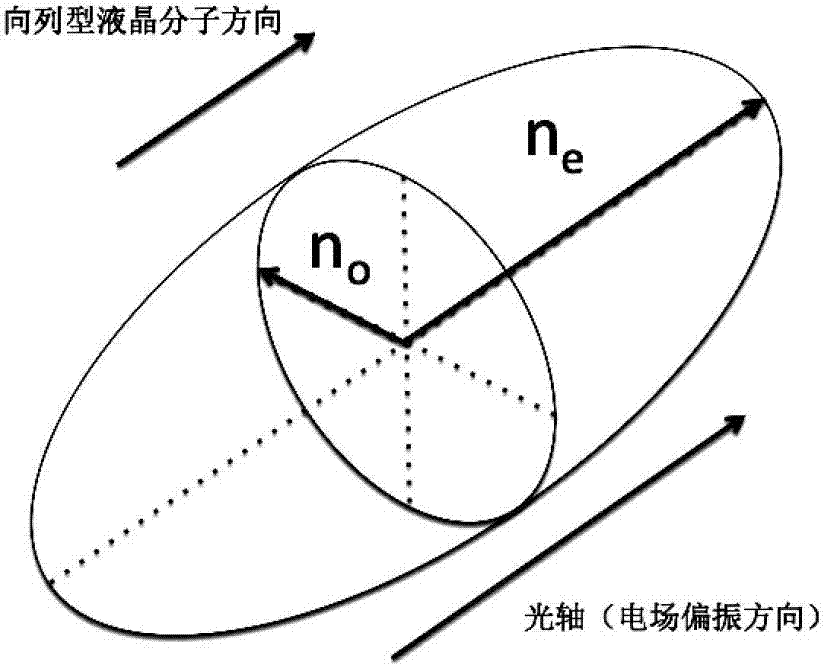

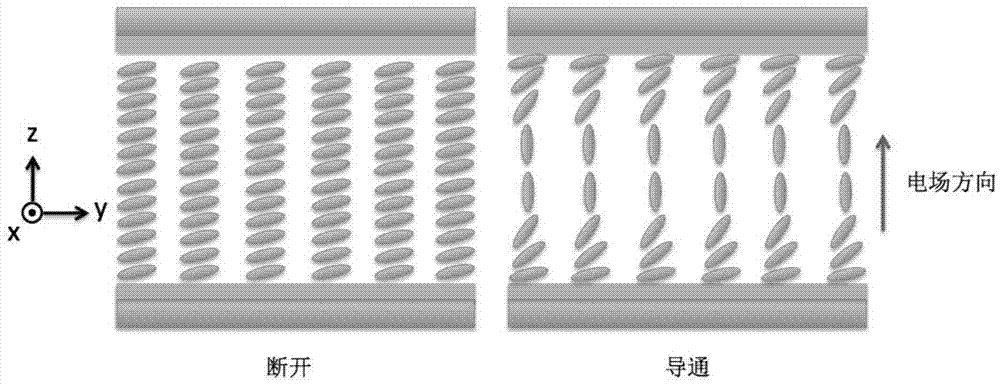

Method used

Image

Examples

Embodiment 1

[0058] The embodiment of the present invention relates to a method for improving the response speed of a phase-controlled silicon-based liquid crystal device: comprising:

[0059] Step S101, increasing the driving voltage to the maximum load voltage Vmax, and completing the maximum voltage driving process;

[0060] In this step, the maximum voltage of the phase-controlled LCOS device driven by the analog circuit is generally around 7V, and the gray scale ranges from 0 to 255; that is, the voltage gradient is divided into 256 levels, and the variation of each level of voltage is (7 / 255) V. According to the description in the previous paragraph, it is assumed that the normal response time of the device should be t i , that is, the response time when the load voltage gray level (N) is i. In the current driving method, the device responds the fastest when adjusting the full phase (2π) value, that is, the moment when the maximum voltage load is applied to the device. According ...

Embodiment 2

[0084] Considering the error of the production process and the error of the optical environment, under normal circumstances, the thickness of the liquid crystal on silicon device will be larger than the required requirement, the working range of the device reaches 2π, and the manufacturing thickness of the device is often slightly higher than the required value; generally 2.5π, or even 3π. This not only ensures the working performance of the device, but also makes the full-phase debugging range more flexible. According to this feature, in the embodiment of the present invention, the interval of the working range is modified, and the original (0, 2π) is shifted to (m, 2π+m), where m is the adjustment step. The purpose of doing this is to improve the slow response of low voltage while keeping the working range unchanged.

[0085] The embodiment of the present invention relates to a method for improving the response speed of a phase-controlled silicon-based liquid crystal device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com