Novel ABC dry powder fire-extinguishing agent and its making method

A dry powder fire extinguishing agent, a new type of technology, applied in fire prevention equipment, etc., can solve the problems of insufficient ammonium dihydrogen phosphate extinguishing ability to extinguish open fire, large amount of crops, increased cost of fire extinguishing agent materials, etc., to reduce material costs and social benefits The effect of large and large economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

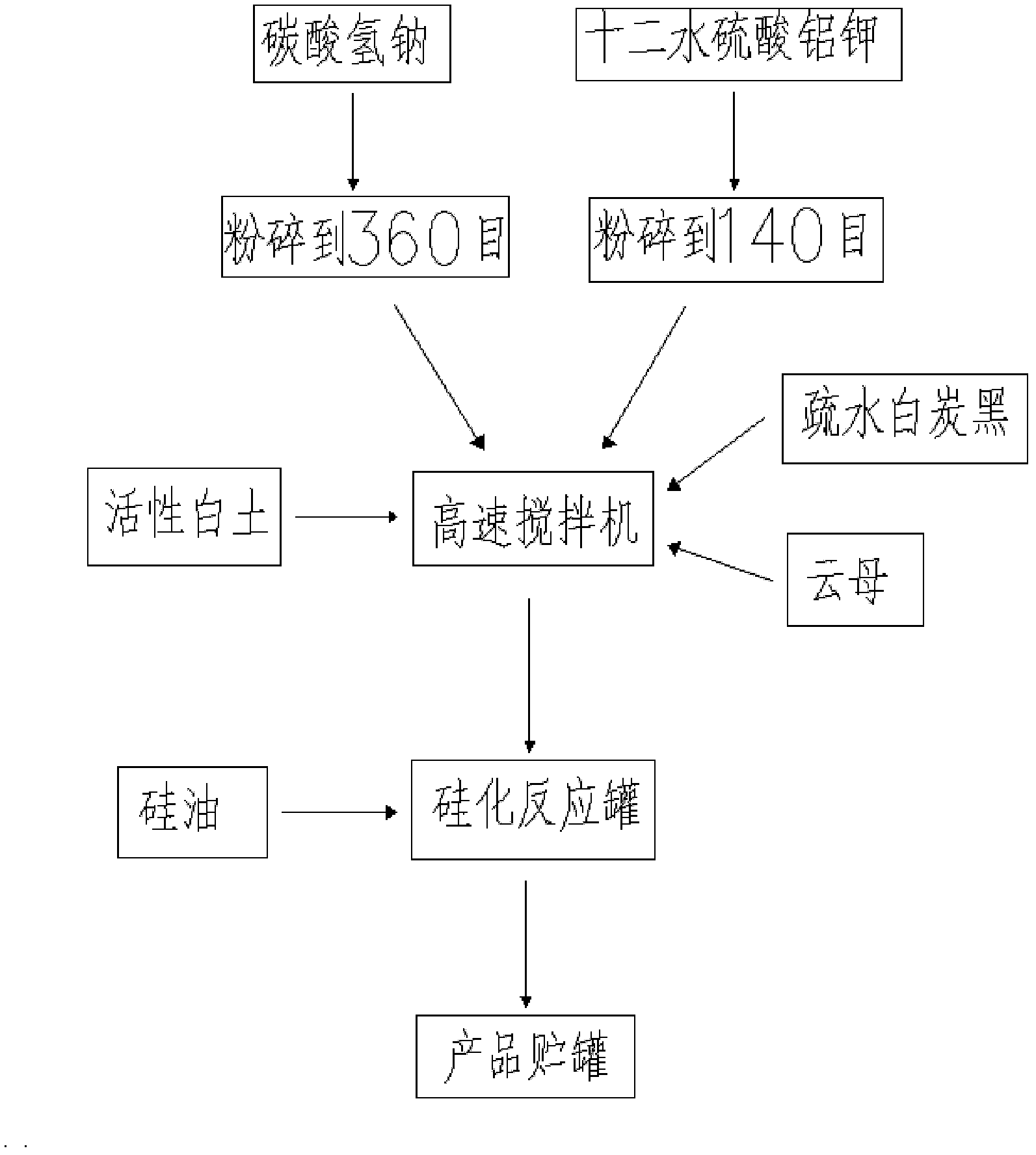

Method used

Image

Examples

Embodiment 1

[0014] Get the sodium bicarbonate that is 45% by weight, be pulverized to particle size and be more than 360 orders; Get the potassium aluminum sulfate dodecahydrate (alum) that is 45% by weight, be pulverized to particle size and be 140 mesh; Be the activated clay of 3 by weight percentage; Mica powder with a percentage of 3; hydrophobic silica with a weight percentage of 3.65; and silicone oil with a weight percentage of 0.35. First put the powder into a high-speed mixer (400-600 rpm) and stir for 30 minutes, transfer the powder into the reaction tank, control the temperature to 60-70°C, spray silicone oil, and take a sample after reacting for 30 minutes. The indicators are qualified and discharged.

Embodiment 2

[0016] Take sodium bicarbonate with a weight percentage of 35, and grind it into an ultrafine powder with a particle size of 360 mesh or more; get 58 weight percent of potassium aluminum sulfate dodecahydrate, and grind it to a particle size of 140 mesh; ; The weight percent is 2.65 hydrophobic silica; The weight percent is 0.35 silicone oil. First put the powder into a high-speed mixer (400-600 rpm) and stir for 30 minutes, transfer the powder into the reaction tank, control the temperature to 60-70°C, spray silicone oil, and take a sample after reacting for 30 minutes. The indicators are qualified and discharged.

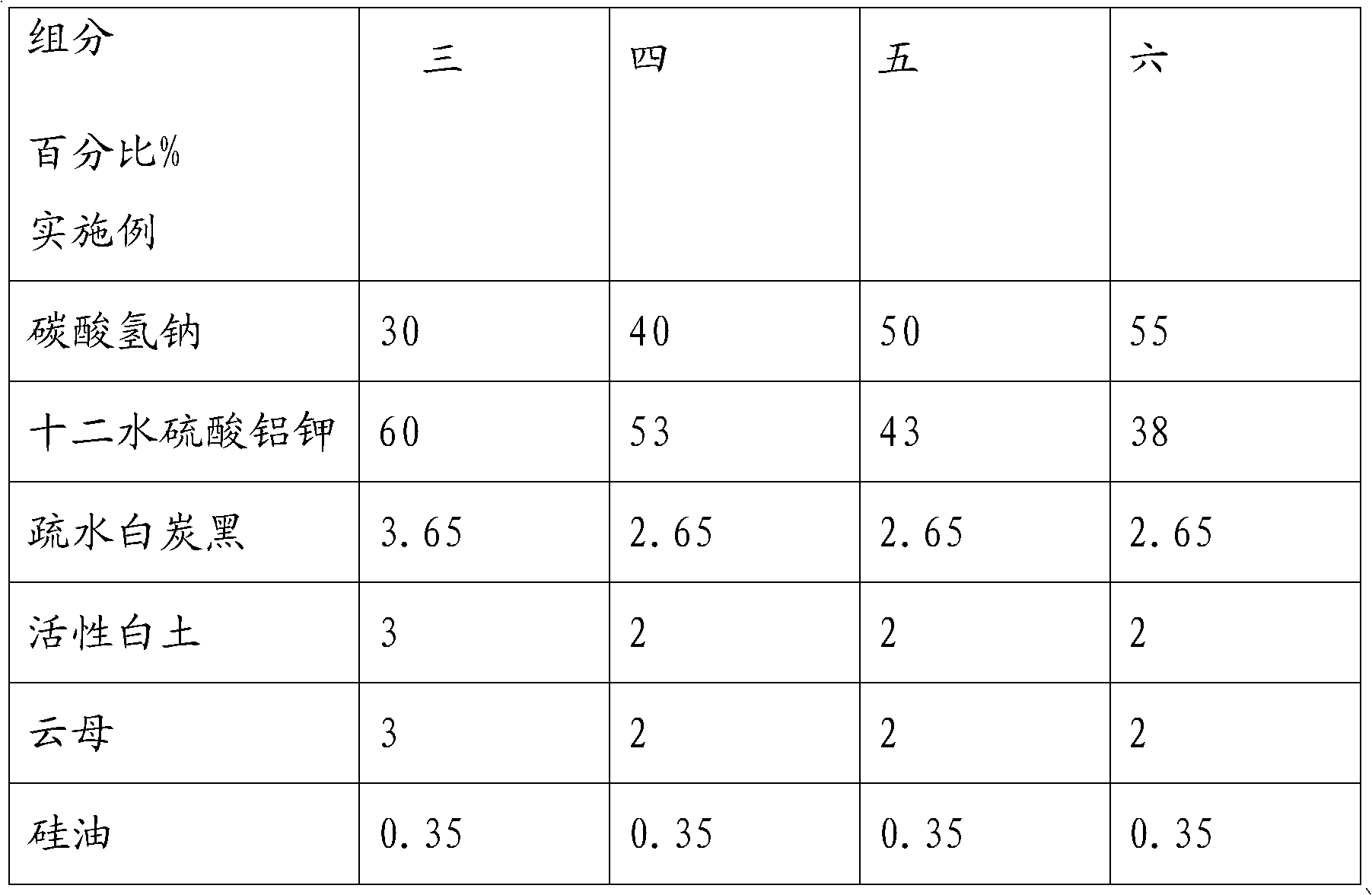

[0017] To the specific proportioning of each component when the present invention is implemented, four embodiments are also provided below, referring to the following table:

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com