Automatic centering coiling device and method for hot rolled coil separating line

A middle-rolling and sub-coiling technology, applied in rolling mill control devices, guiding/positioning/aligning devices, metal rolling, etc., to solve problems such as smashing machinery and equipment, falling steel coils, and deviating from the center position. , to achieve the effect of ensuring equipment and personal safety, improving equipment operation rate, and reducing the probability of falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

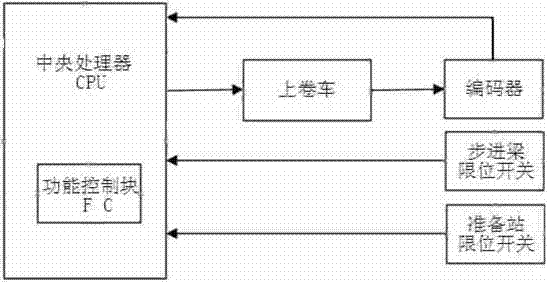

[0028] Depend on figure 1 It can be seen that the automatic centering and coiling device of the hot-rolled coiling line of the present invention is mainly based on the original CPU (central processing unit) and the coiling car, and an incremental encoder is installed in the horizontal running direction of the coiling car. WLCA32-43 travel limit switches are respectively set on the center line of the entrance walking beam and the center line of the preparation station. At the same time, a function control block FC is added to the CPU, and the encoder and two limit switches are respectively connected to the function control block. FC connection.

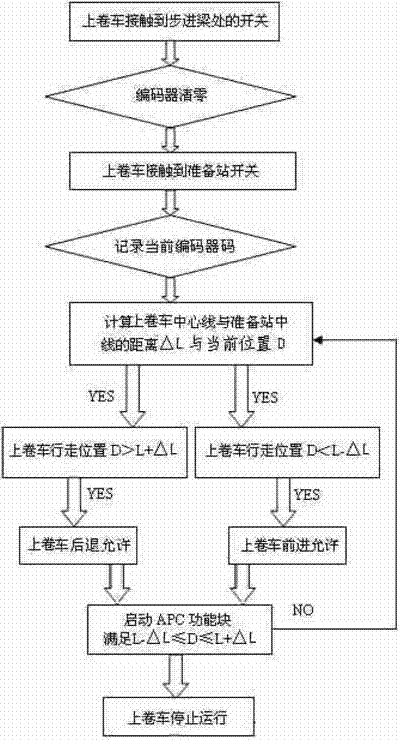

[0029] The specific implementation method and steps of the automatic centering and winding method of the hot rolling sub-coil line of the present invention are:

[0030] First, install the windshield iron on the winding car. When the coiling car runs to the position where its center line coincides with the center line of the preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com