Rotary three-dimensional piezoelectric force measurement cutter handle device

A rotating, three-dimensional technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve problems such as wireless signal transmission, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

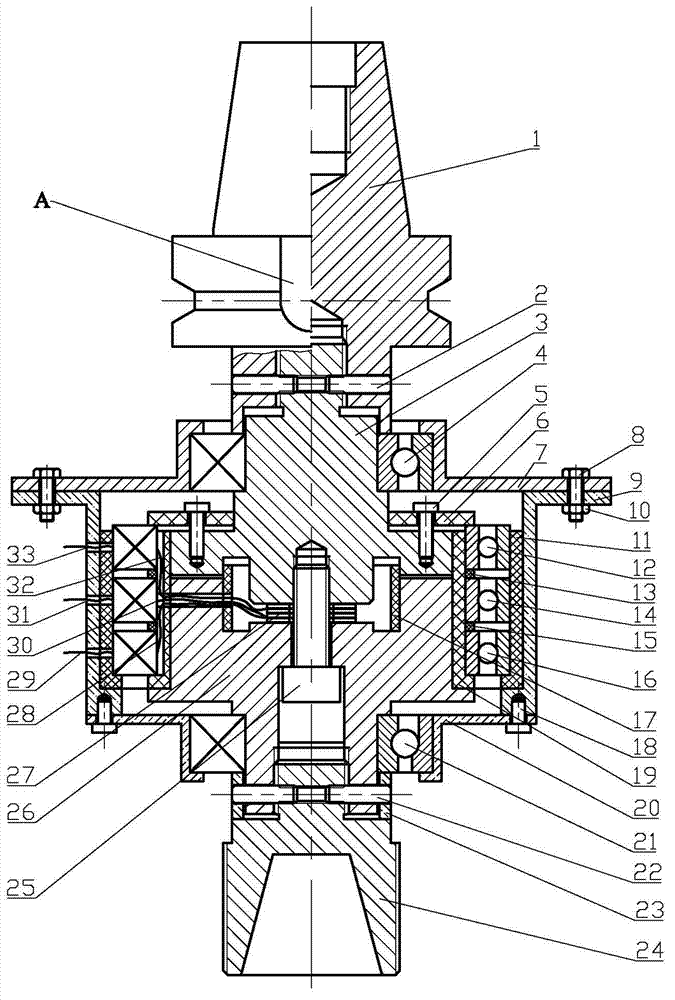

[0013] combined with figure 1 and the technical scheme describe in detail the implementation of the present invention. When milling parts and measuring the cutting force and torque during the milling process, connect the internal thread of the upper end 1 of the milling tool holder of the rotary three-dimensional piezoelectric force measuring tool holder device with the drawing thread, so that the arc shape of the upper end 1 of the milling tool holder Groove A aligns with the positioning block at the end of the machine tool spindle for positioning. The lower end 24 of the handle of a knife cooperates with the tool holder to clamp the tool.

[0014] During processing, the rotation of the main shaft drives the upper end 1 of the milling cutter shank to rotate, and the sensor part connected thereto includes the sensor upper housing 3, the three-dimensional piezoelectric quartz measurement crystal group 27, the inner lead wire 28 of the torque signal, the inner lead wire 30 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com