Dust absorption spray type blackboard eraser

A blackboard eraser and spray-type technology, which is applied in the field of blackboard wiping tools and blackboard erasers, can solve problems such as hard to read blackboard characters, dusty classrooms, and clean blackboards, so as to improve learning efficiency, intuitive working status, and reduce hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

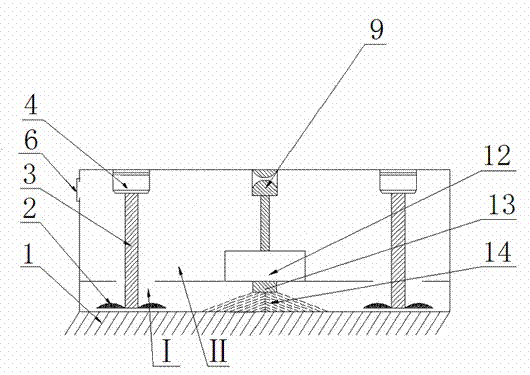

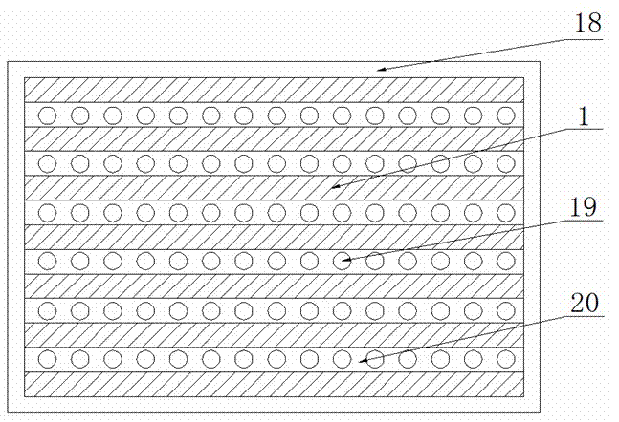

[0017] In this embodiment, see figure 1 with figure 2 , A dust-absorbing spray type blackboard eraser, including a blackboard eraser wiping surface outer shell 18, the outer surface of the blackboard eraser wiping surface outer shell 18 is provided with a brush 1, and the blackboard eraser wiping surface outer shell 18 is provided on the inner surface of the inner surface side. There are fixedly connected spray chamber I and dust storage chamber II. Spray chamber I is adjacent to the blackboard eraser wiping surface outer shell 18. A series of ventilation slots 20 are provided on the outer surface of the blackboard eraser wiping surface outer shell 18, and the dust suction ports 19 are arranged and distributed. In each ventilating groove 20, the dust suction port 19 and the brush 1 are distributed crosswise, and the dust suction port 19 is connected to the dust storage room II. At the same time, the dust dumping outlet 6 is provided on the side wall of the dust storage room II t...

Embodiment 2

[0019] This embodiment is basically the same as the first embodiment, and the special features are:

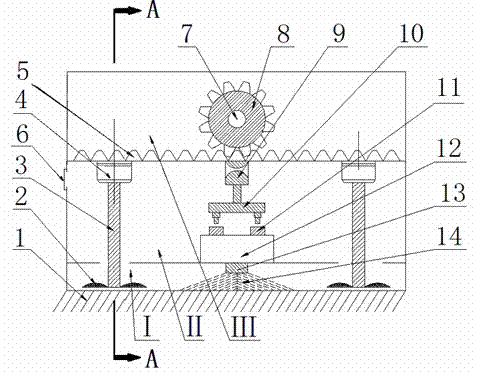

[0020] In this embodiment, see image 3 with Figure 4 , The brush driving equipment room Ⅲ is also connected to the outside of the dust storage room Ⅱ, and the motor 15, gear 8 and rack 5 are arranged in the brush driving equipment room Ⅲ. The transmission shaft 16 of the motor 15 and the gear shaft 7 of the gear 8 pass The coupling 17 is connected so that the gear 8 rotates with the drive shaft 16 of the motor 15. The gear 8 meshes with the rack 5 to form a rack and pinion transmission mechanism, which converts the rotational motion output by the motor 15 into linear movement. The brush 1 is fixedly connected, the position of the motor 15 relative to the bristle driving equipment room III is fixed, the motor 15 rotates forward and backward, driving the rack 5 to reciprocate linearly in the bristle driving equipment chamber III, and then control the reciprocating linear movement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com