Stabilizing method for ocean sailing ships

A technology for ships and oceans, applied in the field of anti-rolling of ships sailing in the ocean, can solve the problems of complex anti-rolling devices and methods, unsatisfactory anti-rolling effect, uneven lateral force, etc., to reduce the force difference and reduce the tilt , the effect of increasing the height of the water surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

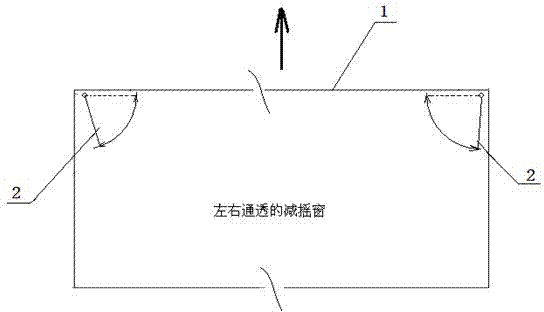

[0027] The hull is 98.5 meters long, 13.2 meters wide, and has a draft of 3.8 meters. On the two side panels of the hull, 35 meters away from the front edge of the hull, a transparent anti-rolling window about 30.5 meters long is opened at 33 meters away from the rear edge of the hull; the width of the anti-rolling window is 1 meter below the waterline, draught 1.2 meters on the line totals 2.2 meters. Taking into account the weight of the ship hull above the anti-rolling window, three steel pipes with a diameter of 200mm are set as the support body in the middle of the anti-rolling window.

Embodiment 2

[0029] The hull is 39.2 meters in length, 6.2 meters in width, and 3.6 meters in draft. At 10.2 meters from the front edge of the hull and 9 meters from the rear edge of the hull, open a 20-meter-long transparent anti-roll window for the hull; the width of the anti-roll window is 1 meter below the waterline, 1.2 meters from the waterline, a total of 2.2 Meter. Leave two partitions in the middle of the anti-roll window, each of which is 1 meter apart. In fact, three independent small anti-roll windows of 2.2 meters by 6 meters are formed. Each small anti-roll window has a wind and wave transparent area of 13.2 square meters. Meters, the total wind and wave transparent area of the hull anti-roll window is 39.6 square meters.

Embodiment 3

[0031] The hull is 88 meters long, 12 meters wide, and has a draft of 3.58 meters. At 10 meters from the front edge of the hull, and at 9 meters from the trailing edge of the hull, at the middle section of the 69-meter hull, a left and right transparent anti-rolling window is opened. The width of the anti-roll window is 0.8 meters below the waterline, and a total of 2.3 meters is 1.5 meters from the waterline. The opening position of the anti-roll window is calculated from 10 meters from the leading edge of the bow, and a 4.5-meter partition is left in the middle of every 6-meter interval. In fact, 7 independent small anti-roll windows of 2.3 meters by 6 meters are formed. The wind and wave transparent area of each small anti-roll window is 13.8 square meters, and the total wind and wave transparent area of the hull anti-roll window is 96.6 square meters. Meter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com