Liquid storage box for realizing internal fluid driving by utilizing temperature difference power source

A fluid-driven, storage tank technology, applied in the field of liquid storage tanks, can solve problems such as difficulty in obtaining power in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

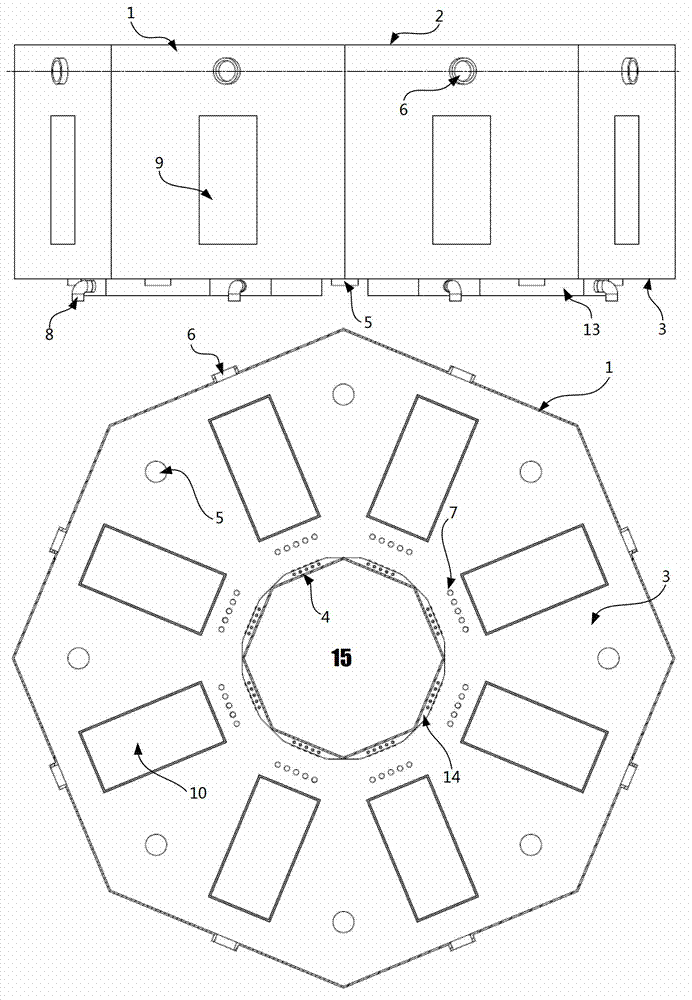

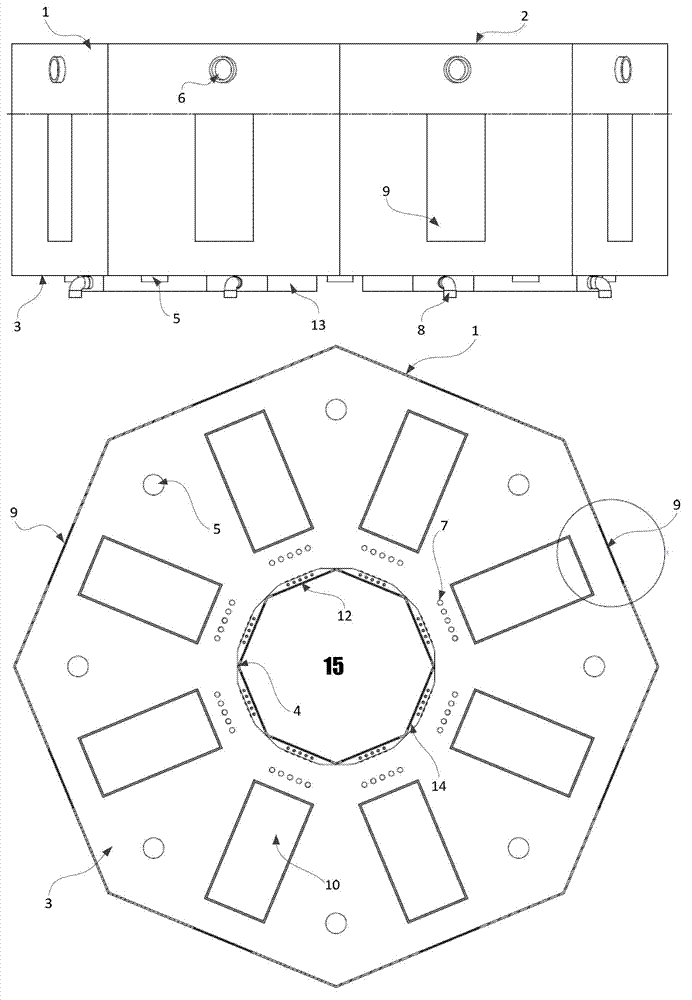

[0032] Such as figure 1 As shown, the present invention provides a liquid storage tank utilizing a temperature difference power supply to realize internal fluid drive. The tank space of the liquid storage tank is composed of the peripheral side wall 1 of the tank body, the tank top cover 2, the tank bottom plate 3 and the tank body The inner ring side wall 4 is surrounded; the horizontal section of the box space is a centrally symmetrical annular polygon, circular ring, polygon or circle; the inner ring side wall 4 of the box is surrounded by a ventilation channel 15 outside the box.

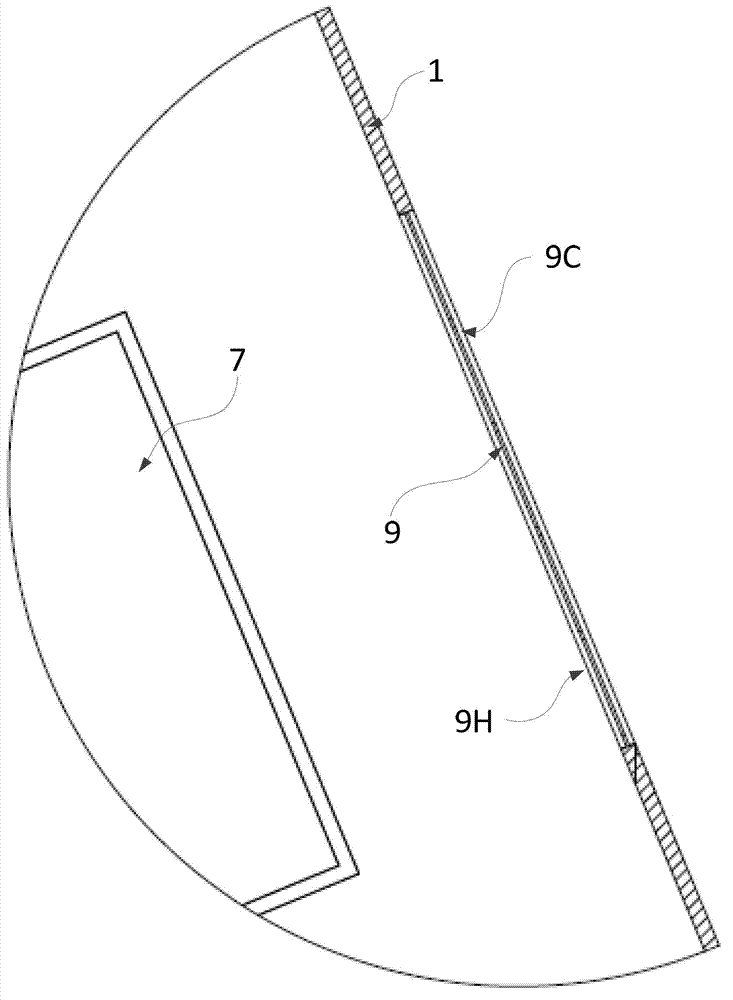

[0033] Such as Figure 1 to Figure 4 As shown, part of the wall of the outer side wall 1 of the box is one or more temperature difference power supplies 9 of the outer side wall of the box, and part of the wall of the box top cover 2 is one or more top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com