Belt cleaner

A cleaner and belt technology, which is applied in the direction of cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of cleaning head wear, long downtime, time-consuming and labor-intensive, etc., to achieve convenient long-term use, no damage to the belt, and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

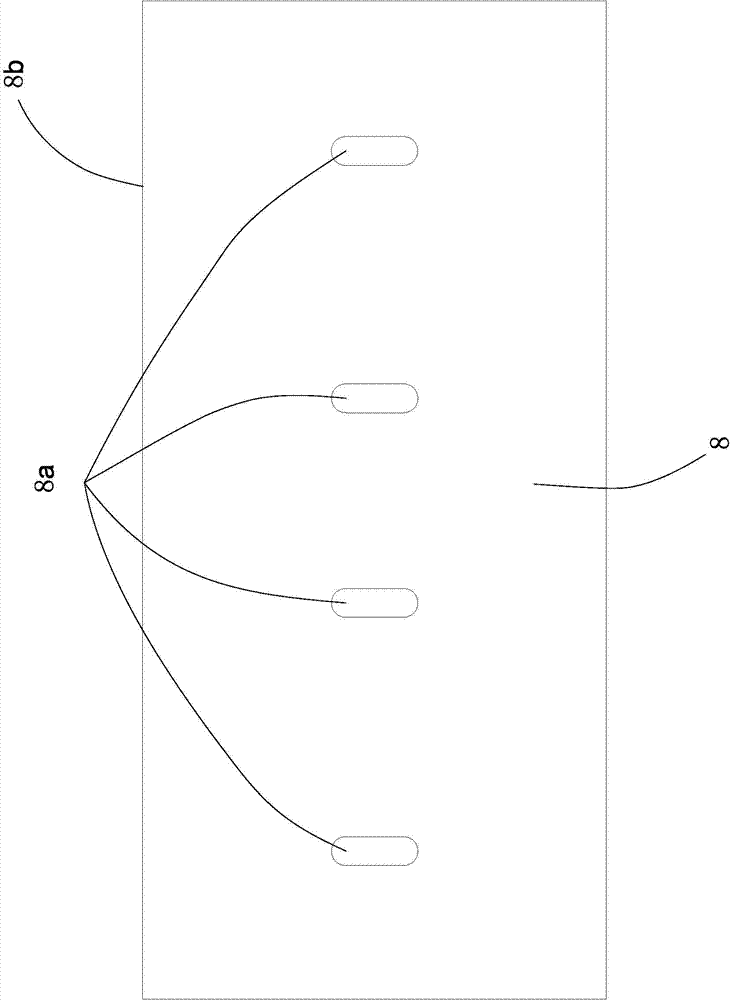

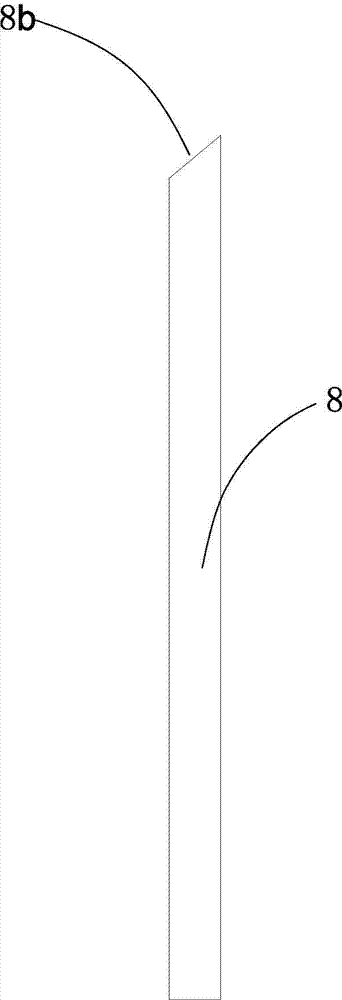

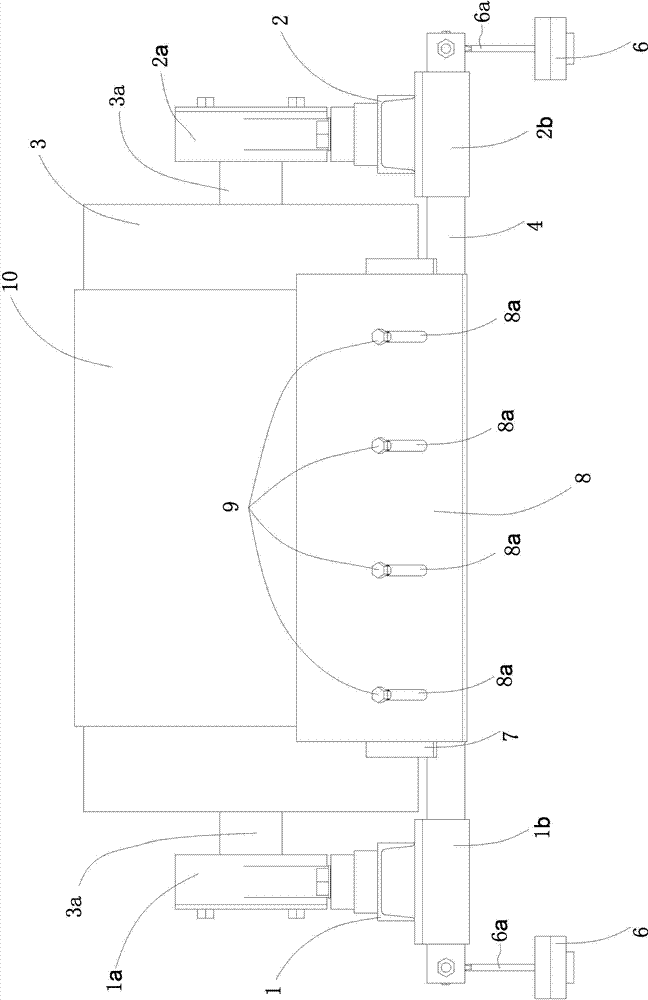

[0018] Such as Figures 1 to 2 As shown, the scraper 8 is a rectangular ultra-high molecular weight polyethylene plate with a thickness of 10mm (molecular weight of more than 3 million). There are four locking through holes 8a in the middle of the scraper 8, and the locking through holes 8a are waist-shaped Through hole, scraper plate 8 rear end has the scraper end surface 8b that contacts with belt 10 on the outer wall of belt drum 3 .

[0019] Such as Figures 3 to 5 As shown, the horizontally arranged left bracket 1 is fixed with a first bearing seat 1a by bolts, and the horizontally arranged right bracket 2 is fixed with a second bearing seat 2a by bolts. The left bracket 1 and the right bracket 2 are coplanar and parallel, and the belt pulley 3 A roller shaft 3a is installed in the axial direction, and the two ends of the roller shaft 3a are respectively matched with the first bearing seat 1a and the second bearing seat 2a, and a belt 10 is attached to the outside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com