A mobile crushing and loading machine

A technology of mobile crushing and loading machine, applied in the direction of conveyor objects, transportation and packaging, loading/unloading, etc., can solve the problems of low mining work efficiency, inability to achieve continuous operation, high production cost, and achieve the expansion of mine production capacity, The effect of improving flexibility and efficiency, and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

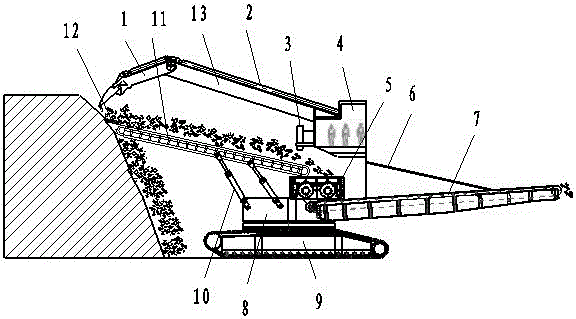

[0021] The present invention comprises crawler belt walking part 9, turning part 8, operating room 4 and working part, and turning part 8 is installed on the crawler belt walking part 9, and operating room 4 and working part are installed on the turning part 8.

[0022] Shown in the figure, its working part is made up of grooving device 12, scraping device, rock conveyor belt 11, particle size control baffle plate 3, crusher 5, reloading conveyor belt 7 and hydraulic cylinder.

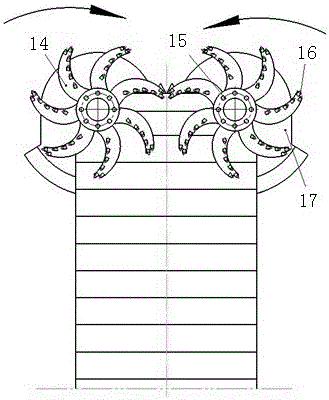

[0023] It is shown in the figure that the cutting device 12 is composed of a cutting arm 14, a rotating wheel 15, a pick 16, and a bucket 17. The cutting device 12 is fixed on the front end of the ore conveying belt 11, and its function is to dig out the ore pile. dig. There are two rotating wheels 15, and a plurality of arc-shaped cutting arms 14 are installed on each rotating wheel 15 circumference. The central axis of the rotating wheel 15 is connected with the motor by a chain. A pick 16 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com