Integrated equipment with supporting and anchoring collaborative operation function

A technology of function and equipment, applied in the field of integrated equipment with the function of collaborative anchor protection, can solve the problems of complex overall structure, large equipment structure, and poor coordination ability of components, and achieve compact space structure, wide application range, and high turning performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] For ease of understanding, the specific structure and working method of the present invention are further described as follows:

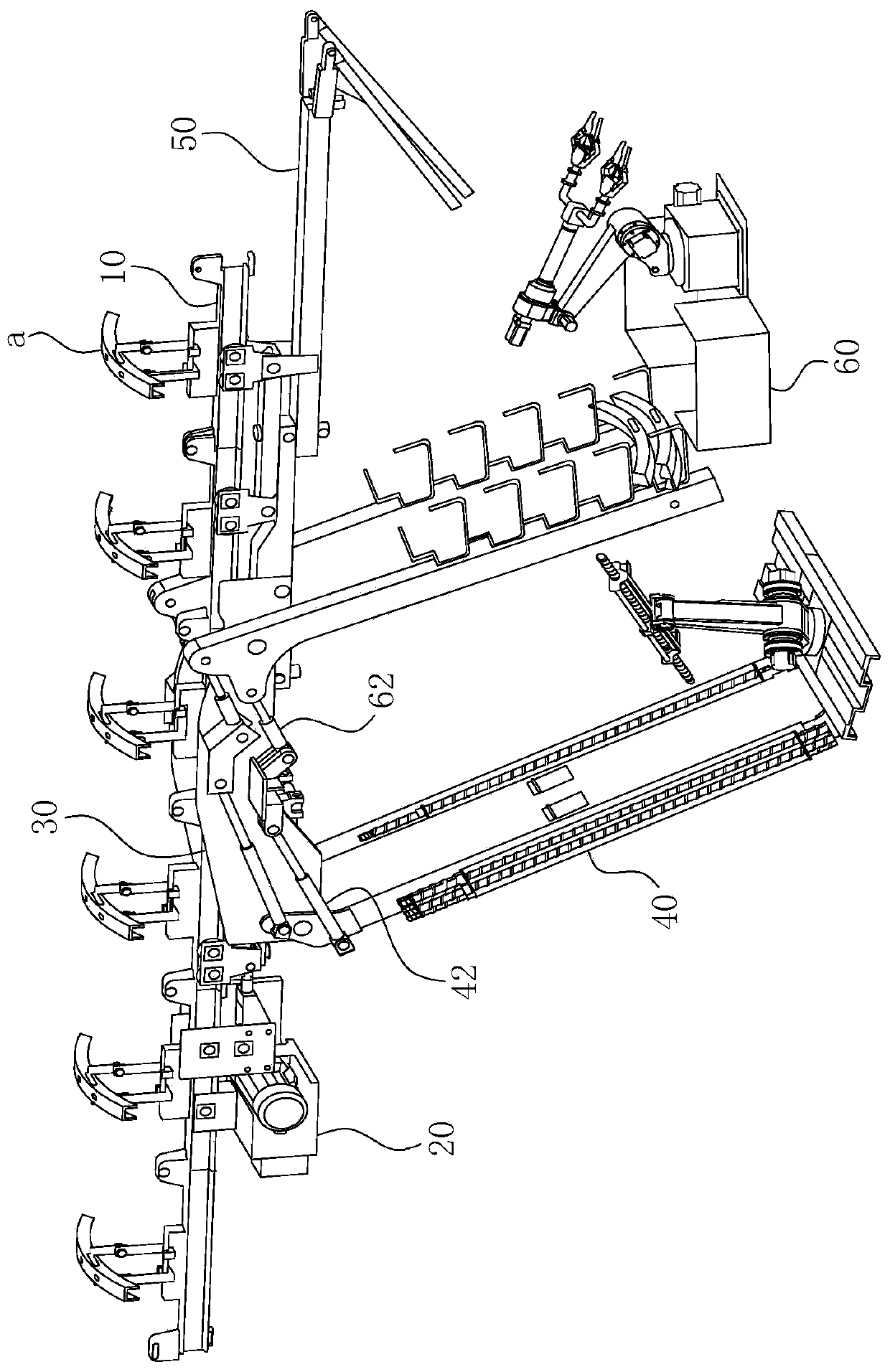

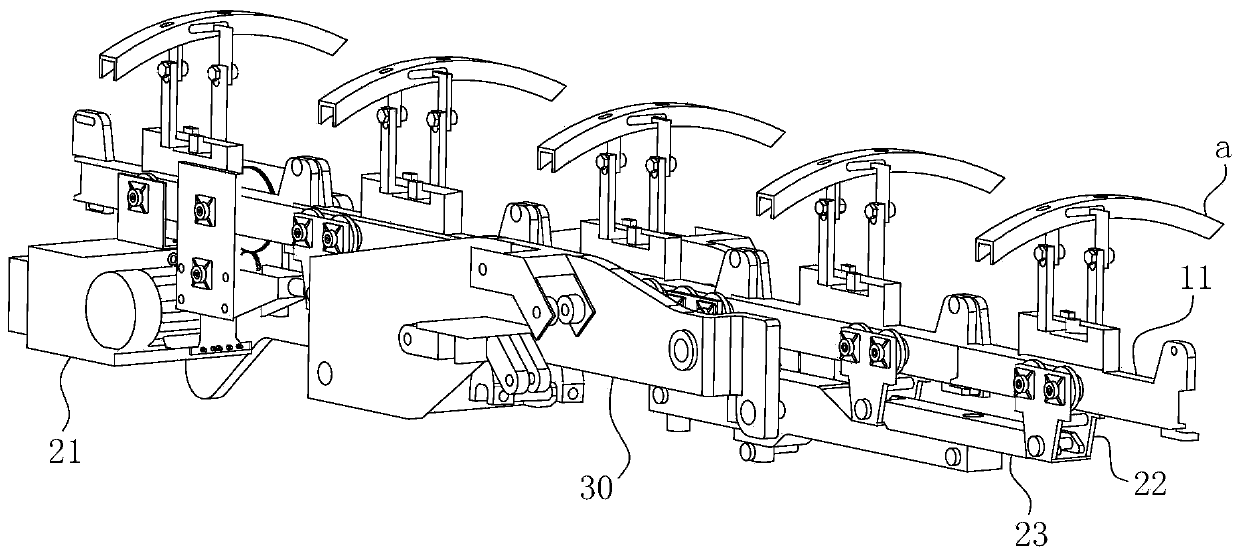

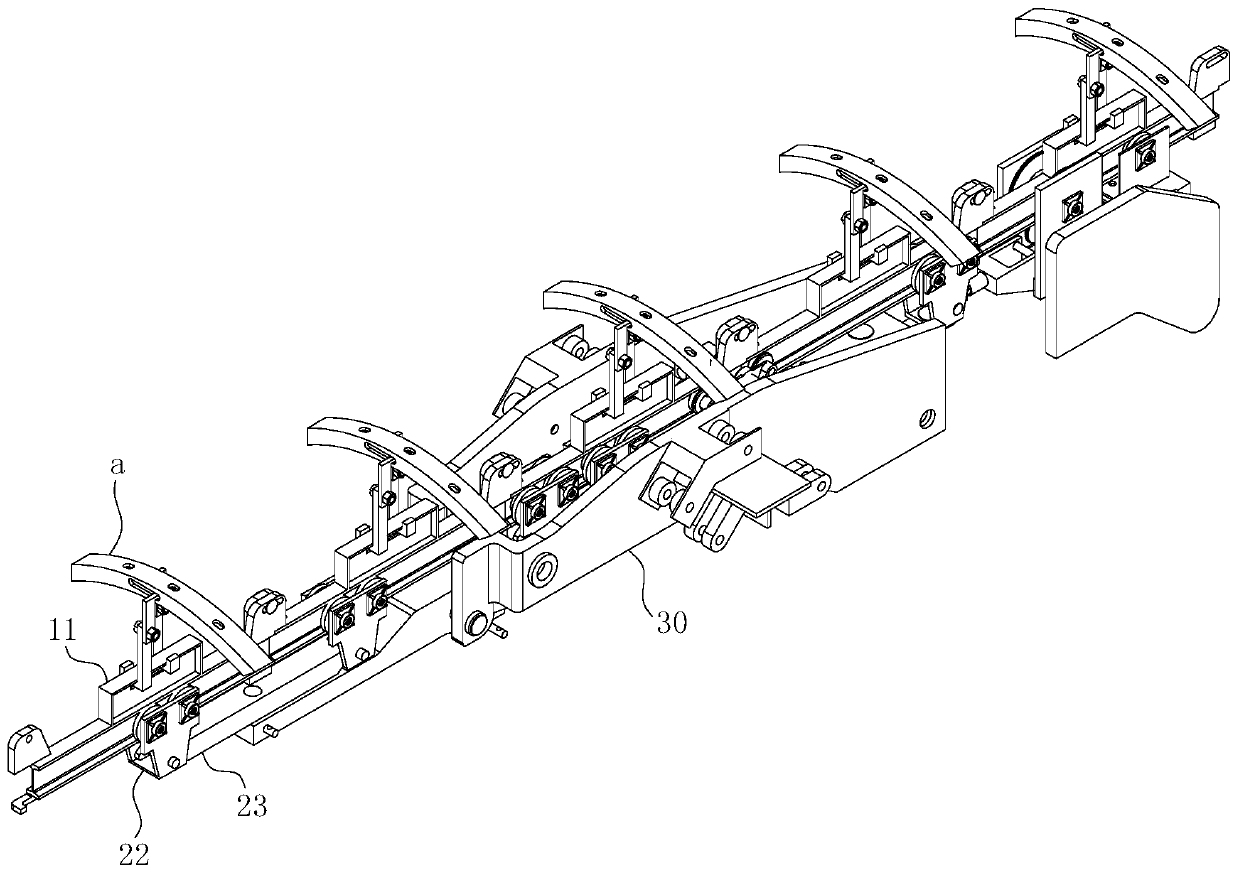

[0067] The concrete implementation structure of the present invention can refer to Figure 1-17 As shown, it is a three-dimensional anchor protection system formed by using the top support U-shaped beam a as the anchor point, and matching the empty rail component 10, the walking component 20, the drilling and anchor unit 40, the auxiliary handling component 60, and the palm-shaped advanced support 50. . In actual use, the functional part can also use other functional structures to form a specific three-dimensional system independently. At once Figure 1-17 As far as the specific embodiment is concerned, the three-dimensional anchor protection system of the present invention is completely independent of the excavation equipment, has an independent working rhythm, occupies relatively less space in the roadway, and each sub-component can make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com