Turbocharged direct-current electric actuating mechanism and method for automatically controlling blade openness thereof

A technology of electric actuators and DC motors, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve problems such as inability to form products, slow response speed, and large power consumption, and achieve fast response, high reliability, and high performance. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

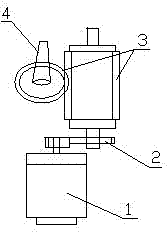

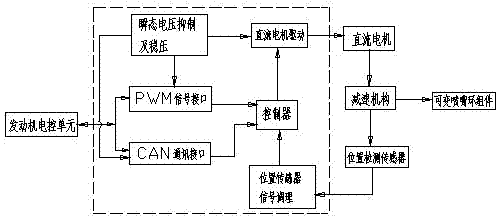

[0011] in figure 1 with figure 2 Among them, the DC electric actuator of the present invention includes a DC motor 1, a deceleration mechanism, a position detection sensor and a circuit control board ( figure 2 In the dashed box), the reduction mechanism includes a transmission gear pair 2, a worm gear pair 3 and a drive crank 4. The two ends of the transmission gear pair are respectively connected with the worm gear pair and a DC motor, and the worm gear pair is connected with the drive crank. The drive crank is connected to the variable nozzle ring assembly on the turbocharger. The circuit control board is provided with a signal processing circuit, and the signal processing circuit includes a transient voltage suppression and voltage stabilization module, a PWM signal interface, and a CAN communication interface , A controller, a DC motor drive module and a position sensor position conditioning module, the transient voltage suppression and voltage stabilization module is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com