Self-detecting self-positioning universal screw machine and positioning method thereof

A screw machine, general-purpose technology, applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of screw machine can not be fully automated positioning, unsatisfactory versatility, etc., to achieve novel ideas, achieve versatility, improve assembly The effect of quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

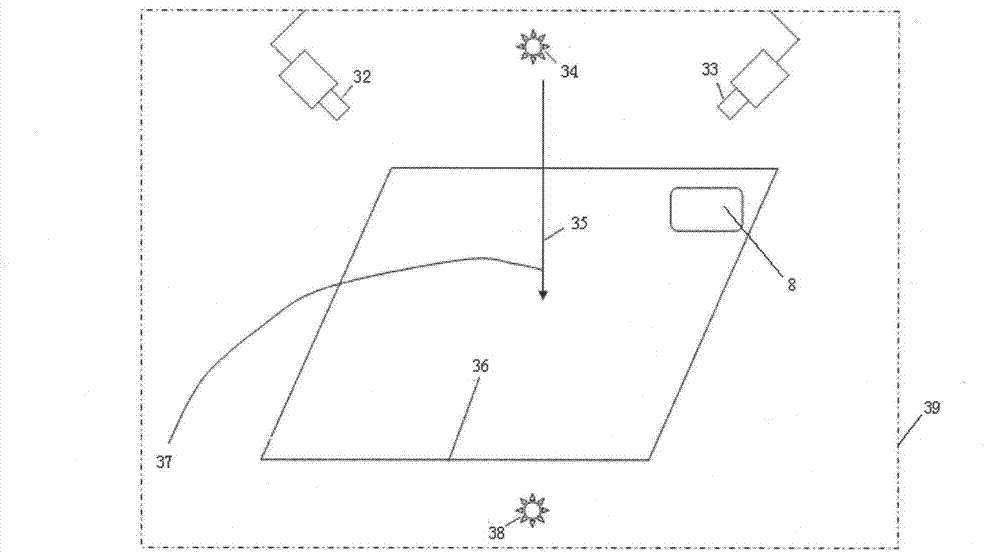

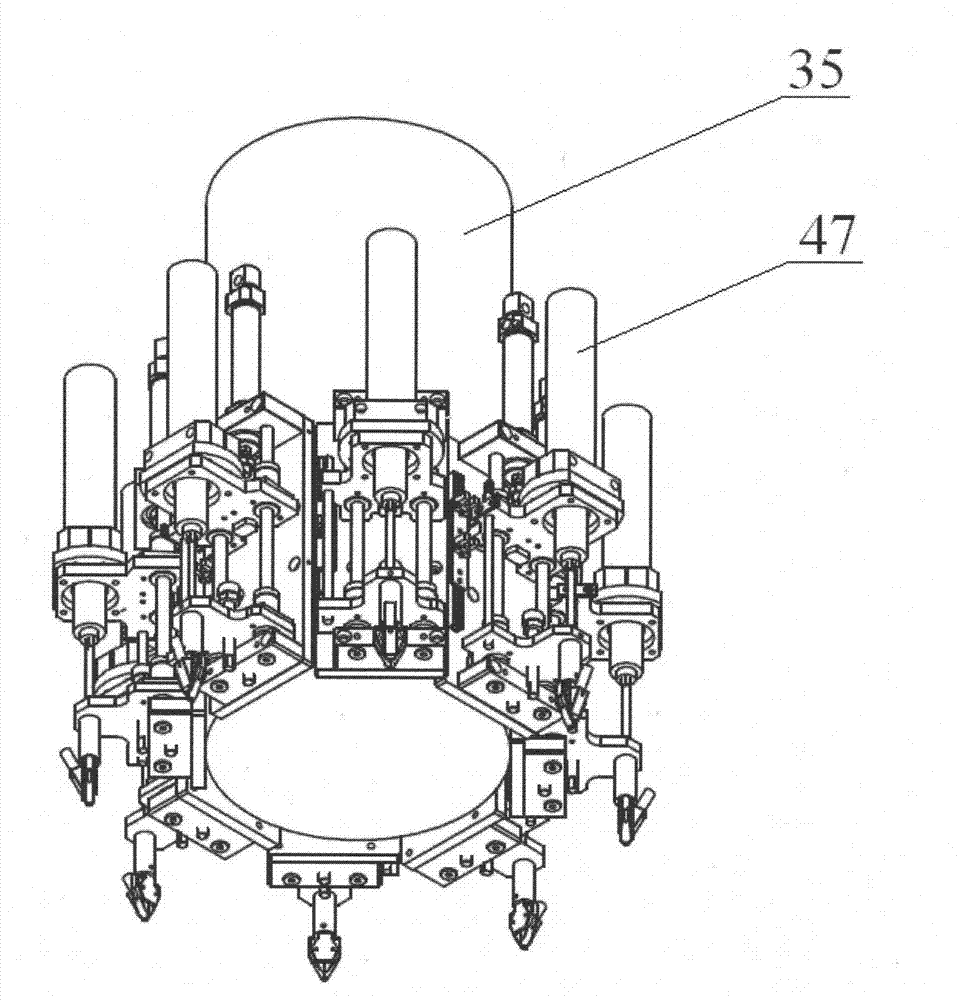

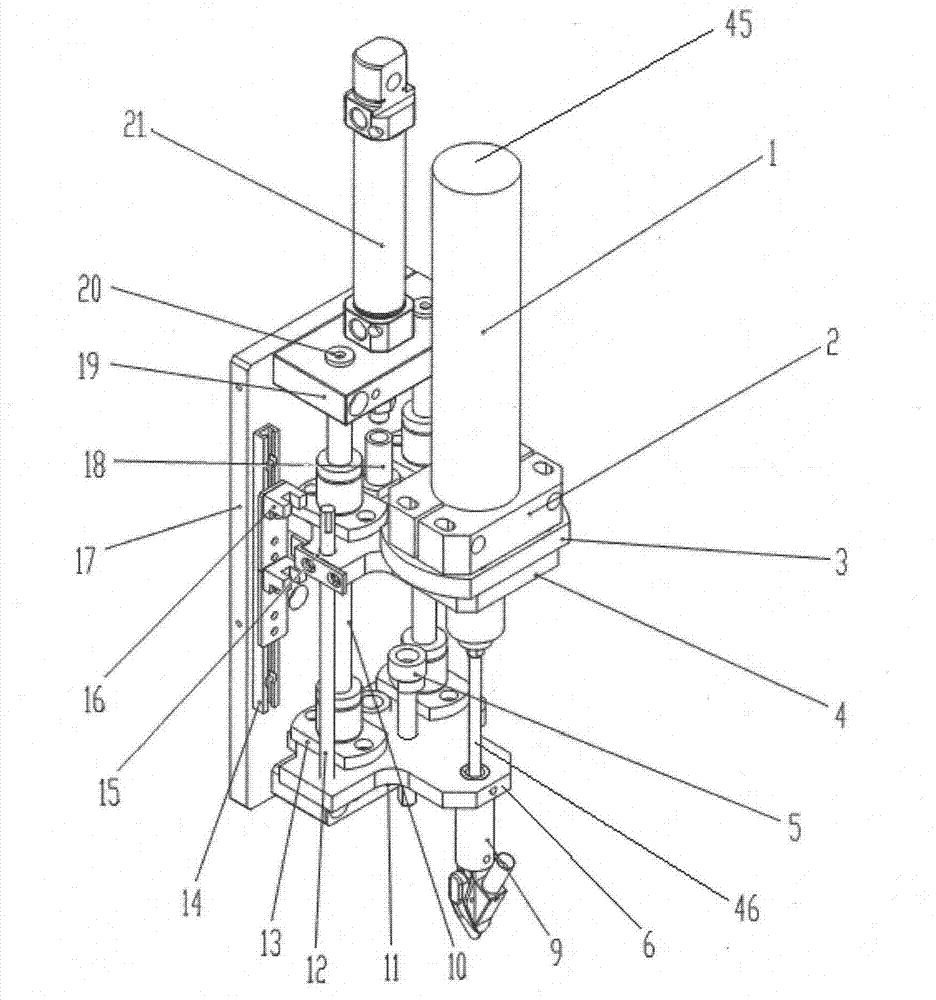

[0034] Such as Figure 1-8 As shown, the structural diagram of the self-checking and self-positioning general-purpose screw machine provided by the present invention includes a screw machine body 36, a screw driving mechanism 35 is arranged on the screw machine body 36 through a frame, and a control system 8 is provided on the screw machine body 36 . Such as figure 2 As shown, eight screwing units 47 are arranged on the main shaft of the screwing mechanism 35 . Such as Figure 3-4 As shown, the screwing unit 47 is fixed on the base plate 17 on the main shaft of the screwing mechanism 35. One side of the base plate 17 is provided with an upper support plate 15 and a lower support plate 6, and the upper support plate 15 is provided with a driving assembly. Be connected with upper support plate 15, lower support plate 6 by guide shaft 10, be provided with limit column one 18 on the upper support plate 15, be provided with limit column two 5 on the lower support plate 6. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com