A kind of 3D glasses and manufacturing method thereof

A technology for 3D glasses and glasses brackets, applied in the field of 3D glasses, can solve problems such as strong nose pressure, difficulty in assembly, unstable electrical connection performance, and difficulty in assembling 3D glasses, and achieves avoidance of wire welding and assembly, light weight, and high electrical performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

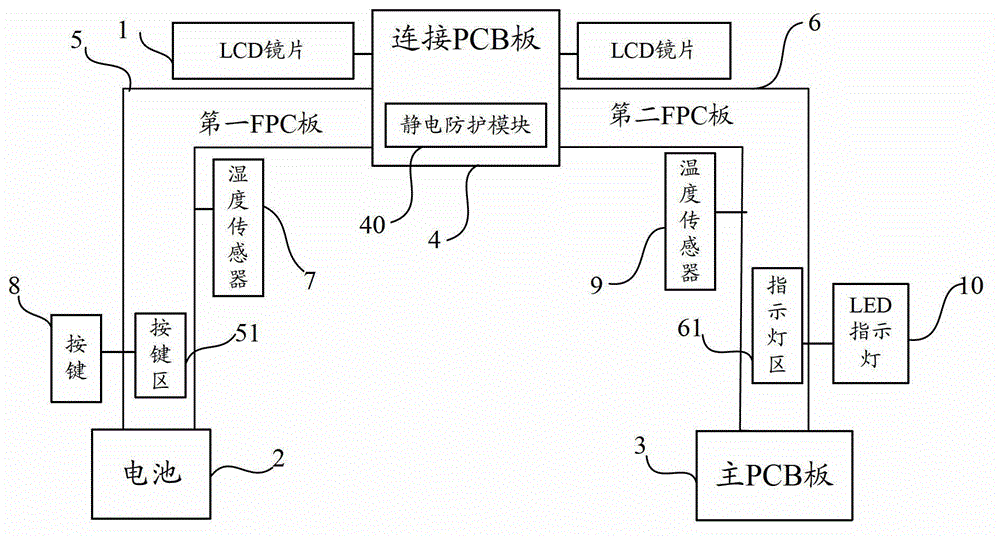

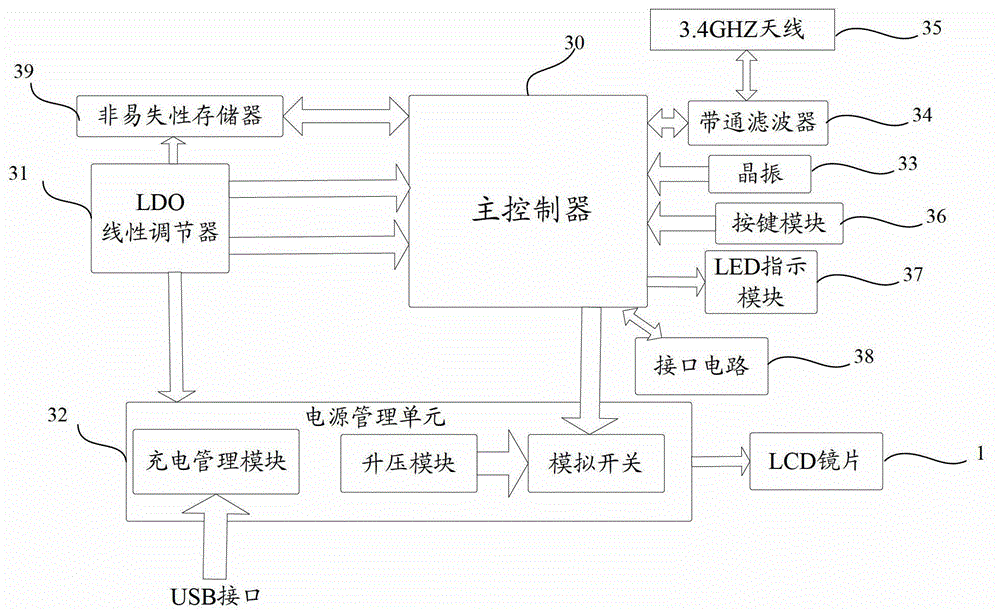

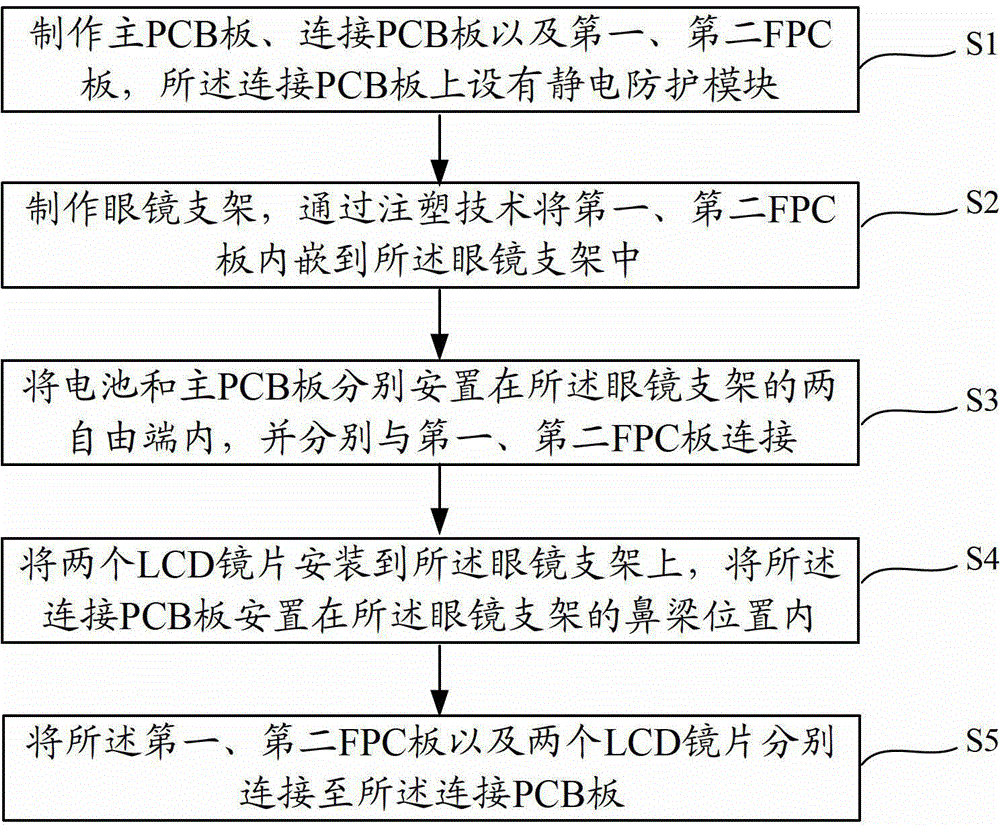

[0025] The core idea of the present invention is to disclose a kind of 3D glasses and its manufacturing method. The 3D glasses include a glasses bracket, two LCD lenses, a battery, a main PCB board, a connecting PCB board and embedded into the glasses bracket by injection molding technology. The first and second FPC boards; the connection PCB board is arranged in the bridge of the nose position of the glasses holder and connects the two LCD lenses; end, and are respectively connected to the connection PCB board through the first and second FPC boards, and the connection PCB board is provided with an electrostatic protection module. The manufacturing method of the 3D glasses includes: making a main PCB board, connecting the PCB board and the first and second FPC boards, the connecting PCB board is provided with an electrostatic protection module; Two FPC boards are embedded in the glasses bracket; the battery and the main PCB board are placed in the two free ends of the glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com