LED (light emitting diode) display unit panel with shading films

A display unit and film technology, applied in electrical components, instruments, circuits, etc., can solve the problems of affecting the viewing angle of the display screen, poor light shape space consistency, and many components and processes. Hole process, improve reliability, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

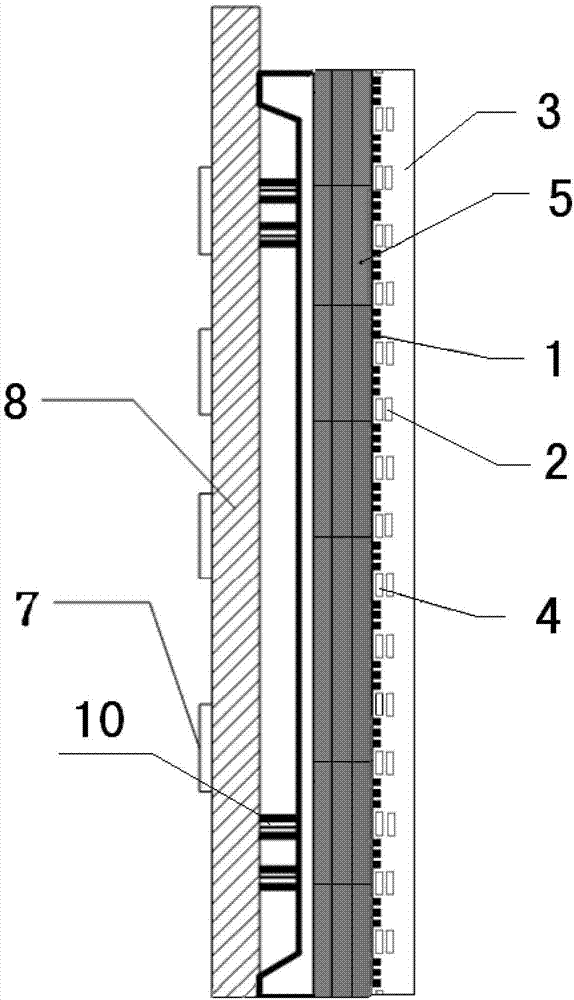

[0025] like figure 2 As shown, the LED display unit board with light-shielding film of the present invention comprises an LED display module made of driver IC7, driver circuit board 8, circuit board 5 and LED wafer 1, transparent mask 3 and light-shielding layer; driver IC7 is welded on On the driving circuit board 8, the rear surface of the circuit board 5 is connected to the driving circuit board 8 by pin headers 10, and m×n LED wafers 1 are fixed on the front surface of the circuit board 5; the light-shielding layer includes the first polarization Sheet 4 and the second polarizer 2, the two polarizers have windows corresponding to the position of each LED wafer 1; the first polarizer 4 is pasted on the front surface of the circuit board 5, and the second polarizer 2 is pasted on the first polarizer on the sheet 4, and the polarization directions of the first polarizer 4 and the second polarizer 2 are perpendicular to each other; the transparent mask 3 is a transparent enca...

Embodiment 2

[0036] like image 3 As shown, the LED display unit board with light-shielding film of the present invention comprises an LED display module made of driver IC7, driver circuit board 8, circuit board 5 and LED wafer 1, transparent mask 3 and light-shielding layer; driver IC7 is welded on On the driving circuit board 8, the rear surface of the circuit board 7 is connected to the driving circuit board 8 by a row of pins and sockets 10, and the LED wafer 1 is fixed on the front surface of the circuit board 5; the light-shielding layer includes a first polarizer 4 and a second polarizer sheet 2, the first polarizer 4 is bonded to the front surface of the circuit board 5, and a window is opened corresponding to the position of the LED wafer 1; the transparent mask 3 is a transparent encapsulation colloid, and the transparent encapsulation colloid is encapsulated between the first polarizer 4 and the On m×n LED wafers 1, the LED wafers 1 are embedded in the transparent packaging coll...

Embodiment 3

[0045] like Figure 4 As shown, the LED display unit board with light-shielding film of the present invention includes an LED display module composed of a driver IC7, a circuit board 6 and an LED wafer 1, a transparent mask 3 and a light-shielding layer; m×n LED wafers 1 are fixed on the front surface of the circuit board 6; the driver IC7 is fixed on the rear surface of the circuit board 6, and the driver IC is directly connected to the LED wafer through the circuit board 6; the light-shielding layer includes a first polarizer 4 and a second polarizer 2, both The polarizers have windows corresponding to the positions of the LED wafers 1; the first polarizer 4 is pasted on the front surface of the circuit board 6, the second polarizer 2 is pasted on the first polarizer 4, and the first polarizer 4 The polarization direction of the second polarizer 2 is perpendicular to each other; the transparent mask 3 is a transparent packaging colloid, and the transparent packaging colloid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com