Secondary equipment for front-board installation, front-board wiring, and front-board operation

A technology of secondary equipment and front wiring, applied in the directions of busbar/line layout, substation/switch layout details, electrical components, etc., which can solve the problems of unfavorable external logo and product name spraying or pasting, narrow space, and increased manufacturing costs, etc. , to achieve the effect of ensuring the integrity of the appearance, reducing the number of cabins, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

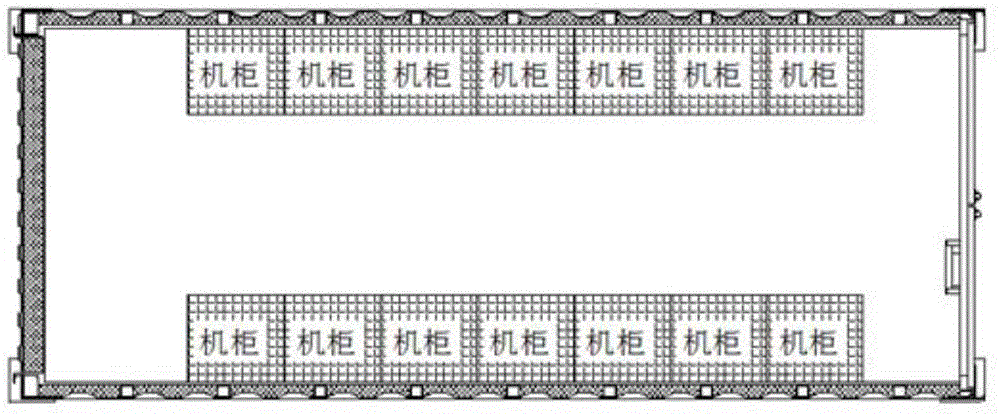

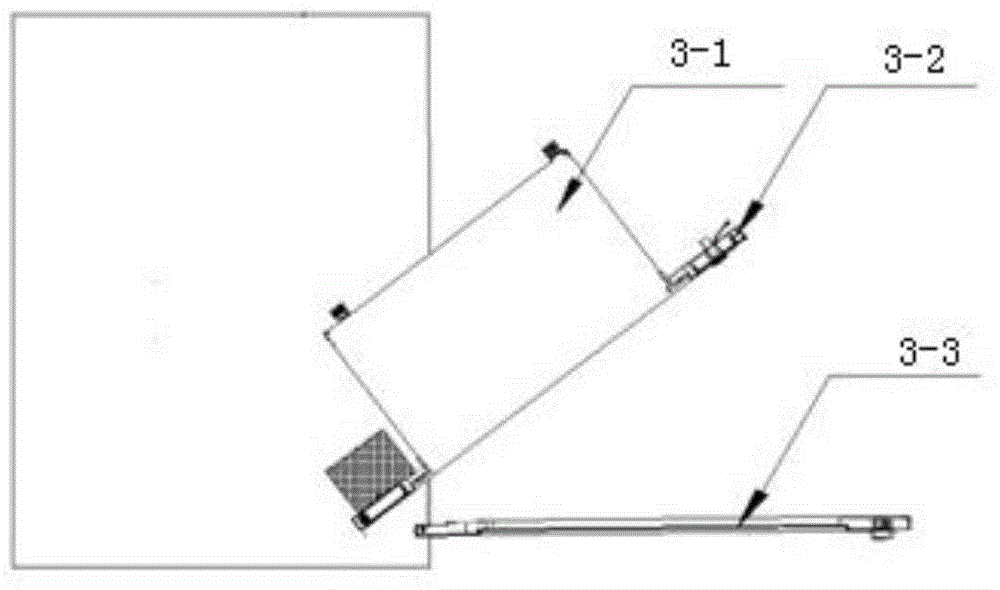

[0031] Such as Figure 4 As shown, the traditional secondary equipment adopts the method of front-panel installation and rear-panel wiring. The human-computer interaction module 1 is located on the front side of the device, and there is a motherboard 3 inside the box body 4. The connectors are connected to each other. The plug-in 2 is provided with a wiring interface and a test port. The end face of the plug-in faces the opposite direction to the human-computer interaction module. When wiring or testing, pull out the plug-in 2 from the end face, such as Figure 4 The direction indicated by the arrow in the middle; if it is necessary to monitor the status of the system or press keys, etc., the user needs to operate on the human-computer interaction module 1 in front.

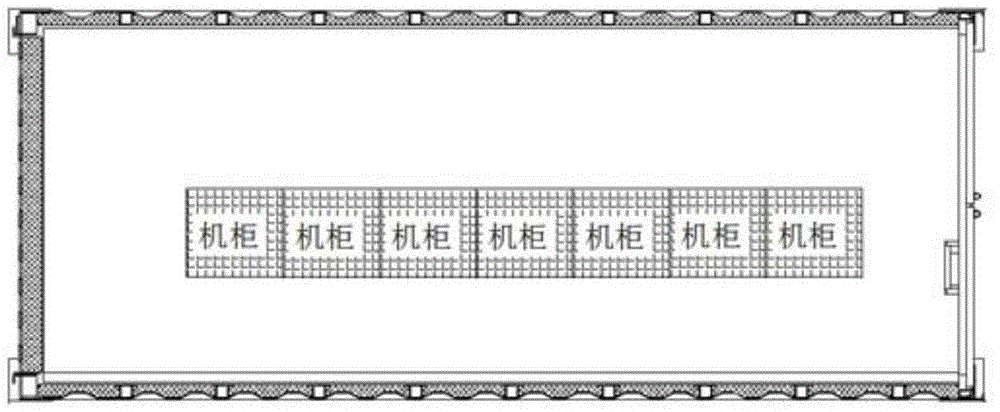

[0032] Such as Figure 5 As shown, the secondary equipment device for fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com