Albumen hydrolysate and method for producing same

A manufacturing method and technology of clear water, applied in food science, food preparation, animal protein processing and other directions, can solve the problem of inability to reduce the sulfur smell of egg white, and achieve the effect of reducing the amount of hydrogen sulfide and expanding the demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

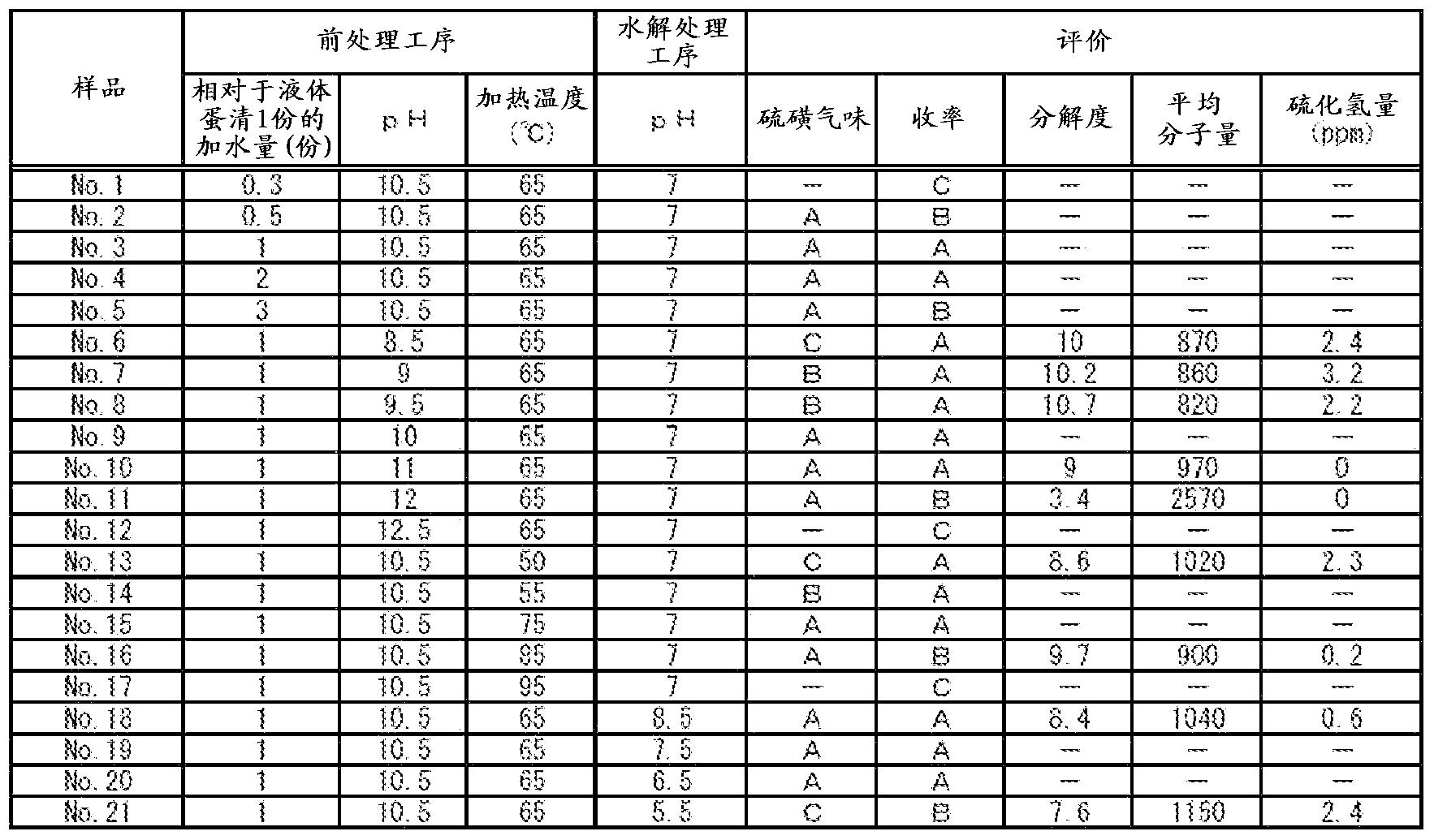

Image

Examples

Embodiment 1

[0072] The diluted egg white solution obtained by diluting 1 part of raw egg white with an equal amount of water was adjusted to pH 10.5 with an aqueous sodium hydroxide solution, and then heated at 70° C. for 30 minutes to perform pretreatment. After the pretreated egg white dilution was adjusted to pH 7.0 with hydrochloric acid aqueous solution, 2,000 units of neutral protease (Sumizyme FP, manufactured by Shin Nippon Chemical Industry Co., Ltd.) was added, and hydrolysis was performed at 40°C for 6 hours. Next, protease inactivation treatment was performed by heating at 90° C. for 15 minutes to obtain the egg white hydrolyzate of the present invention. Moreover, the soluble egg white hydrolyzate of this invention was obtained by filtering the obtained egg white hydrolyzate, and removing the insoluble matter.

[0073] The obtained egg white hydrolyzate and soluble egg white hydrolyzate were consumed, and as a result, the sulfur odor was sufficiently reduced.

[0074] The av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com