Process for shredding tobacco stems by dry ice

A technology of shredded tobacco stems and dried tobacco stems, which is applied in the fields of tobacco, tobacco processing, application, etc., can solve the problems of waste and the inability to cut tobacco stems into shreds, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

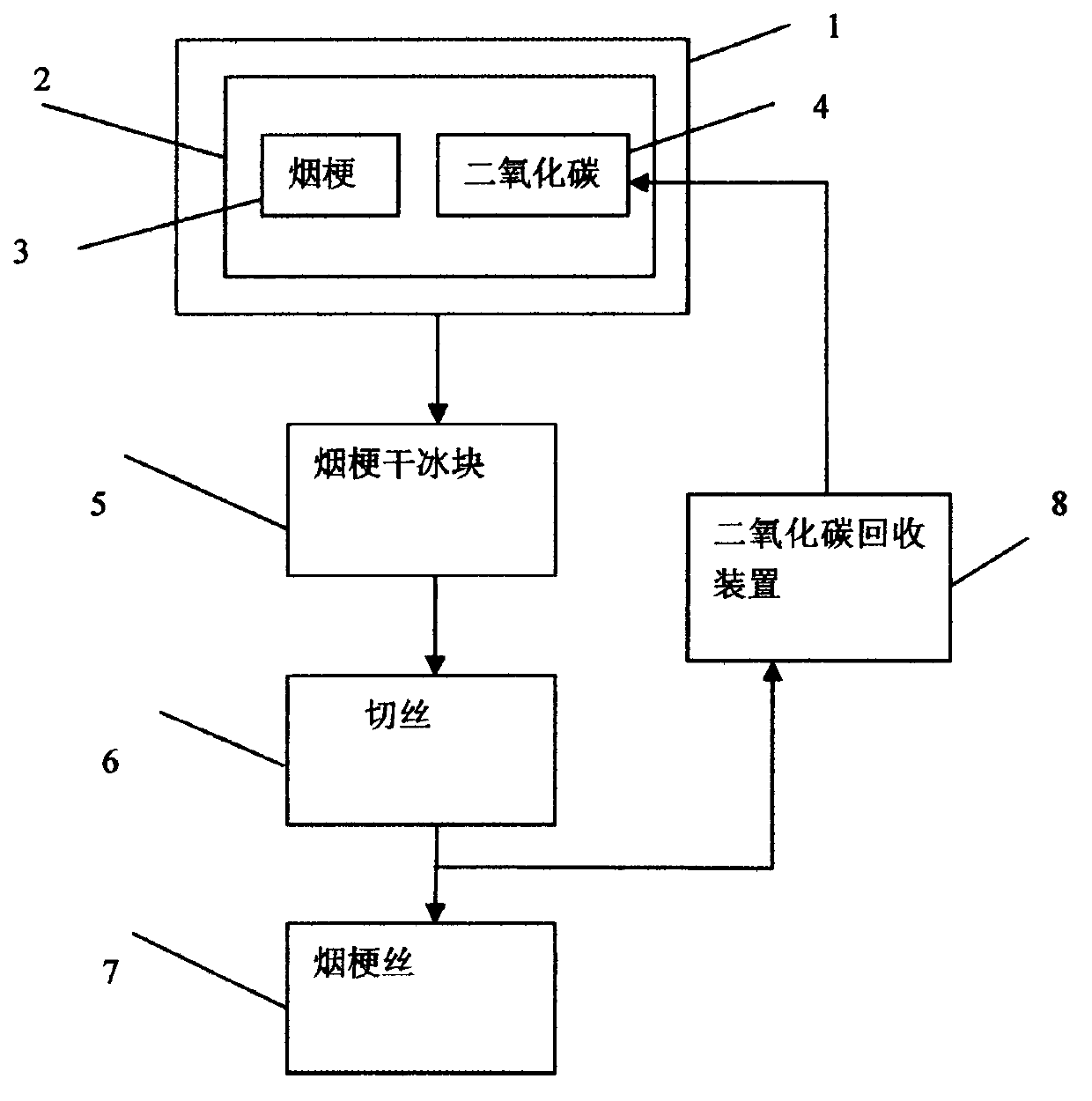

[0009] exist figure 1 Among them, in the dry ice production device (1), the special container (2) is equipped with tobacco stems (3) and carbon dioxide (4), through the production procedure of the dry ice production device (1), the tobacco stems (3) and carbon dioxide (4) are condensed Tobacco stem dry ice cubes (5), take out the tobacco stem dry ice cubes (5) and cut them into shreds (6) according to the specification with a shredder, after the carbon dioxide (4) is sublimated, the tobacco stem shreds (7) are obtained, and the sublimated carbon dioxide enters The carbon dioxide recovery device (8) is recycled to the special container (2) for utilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com