Heating panel for cooking tool and frying dish used by heating panel

A technology for heating panels and panels, applied in applications, home appliances, kitchen appliances, etc., can solve the problems of difficult temperature control, affecting the cooking quality of frying pans, and temperature control errors, so as to improve accuracy and timeliness, and avoid limitations. Sexuality and hysteresis, the effect of expanding the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

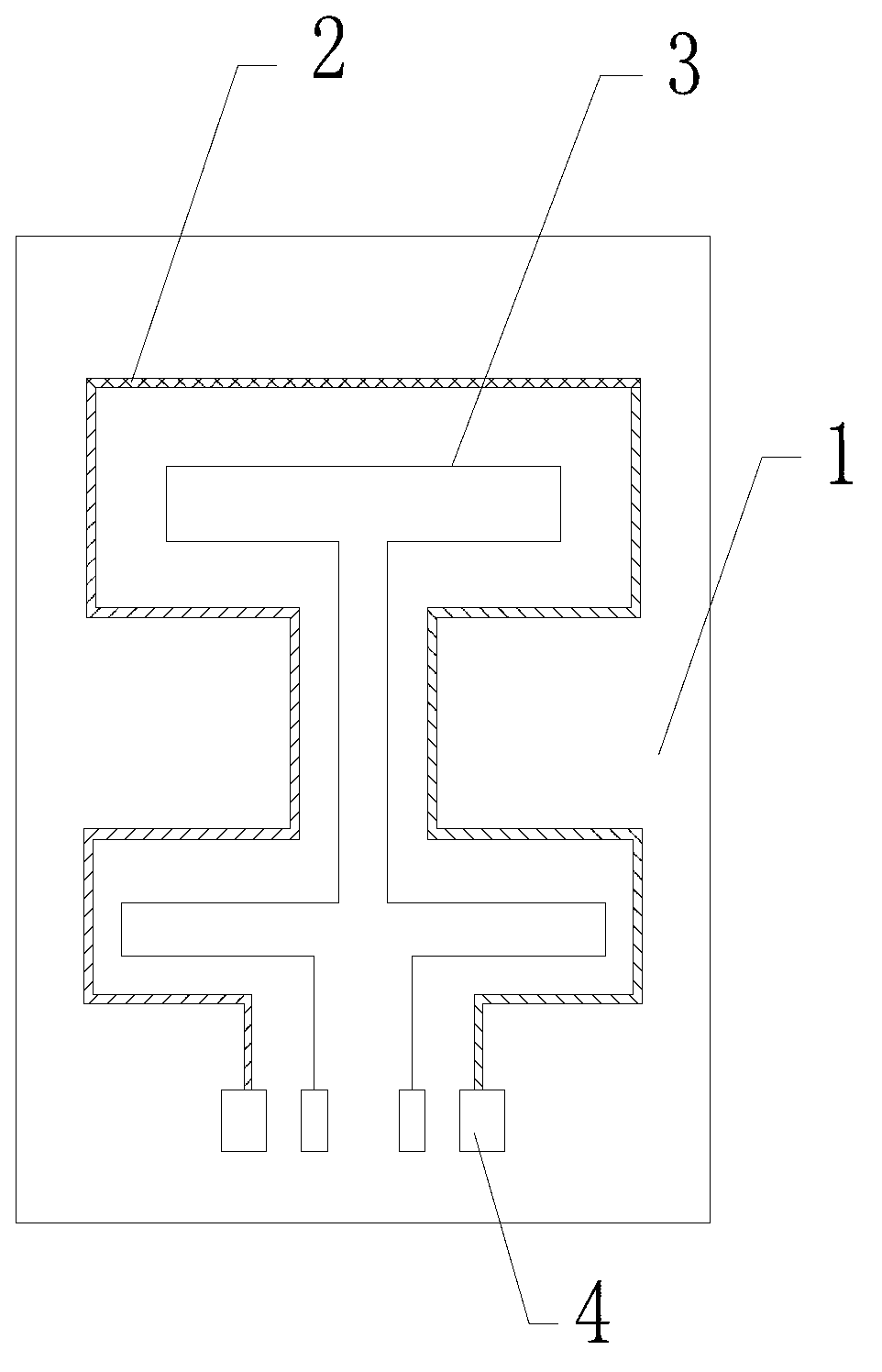

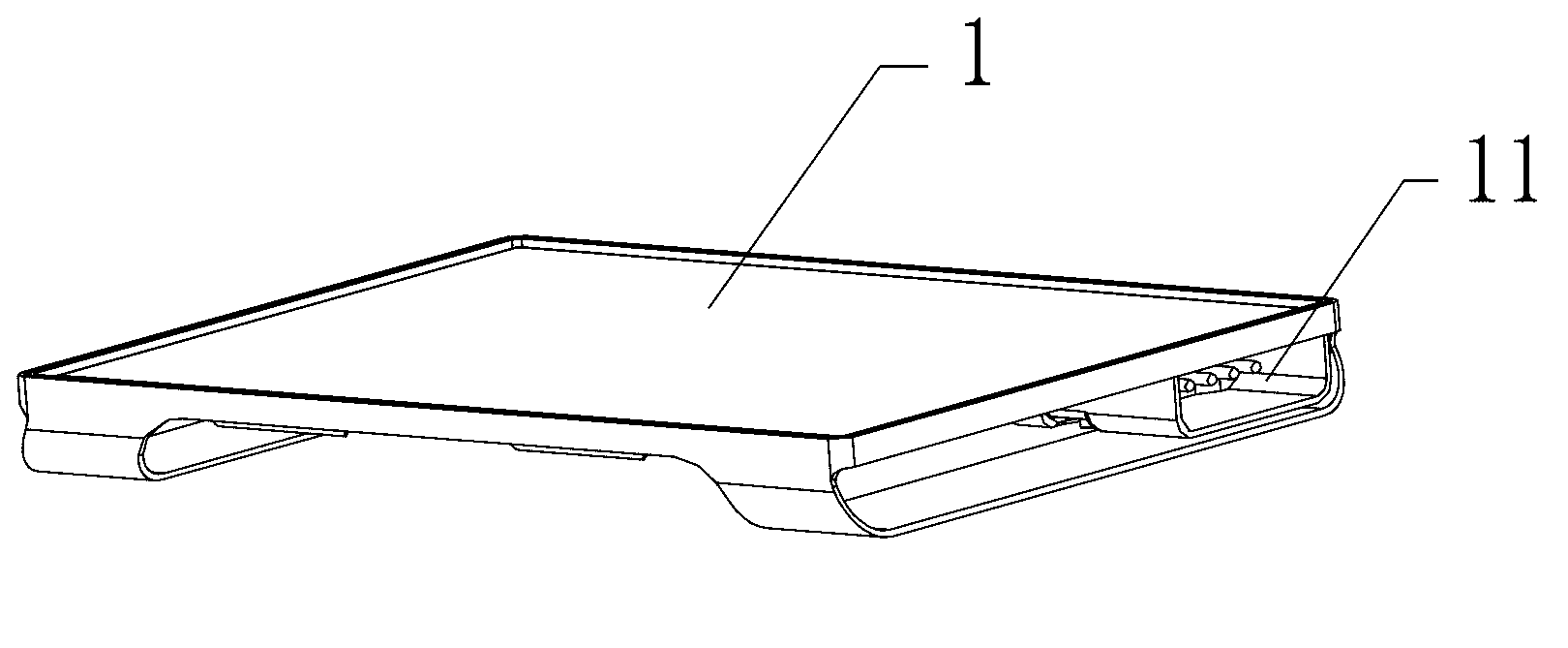

[0027] The heating panel of the present invention is as figure 1 As shown, the panel 1 is printed with a rare-earth thick-film heating circuit 2 and a rare-earth thick-film temperature-sensing resistance line 3 , and a layer of first insulating layer is covered above the rare-earth thick-film heating circuit 2 and the rare-earth thick-film temperature-sensing resistance line 3 ; The rare-earth thick-film heating circuit 2 is arranged in a multi-section zigzag shape, so that the whole is in an I-shape (according to requirements, the rare-earth thick-film heating circuit 2 can be arranged in one or more sections of S-shape, M-shape or arc); the rare-earth The thick-film temperature-sensing resistance wire 3 is arranged along the setting path of the rare-earth thick-film heating circuit 2, so that the rare-earth thick-film temperature-sensing resistance wire 3 is also arranged in a multi-section zigzag, and the whole is also in an I-shaped shape (the rare-earth thick-film temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com