Stirring method

A mixing method and technology for a mixer, which are applied to mixer accessories, chemical instruments and methods, mixers with a rotating mixing device, etc., can solve problems such as failure to use normally and the mixer is stuck, avoid being stuck, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

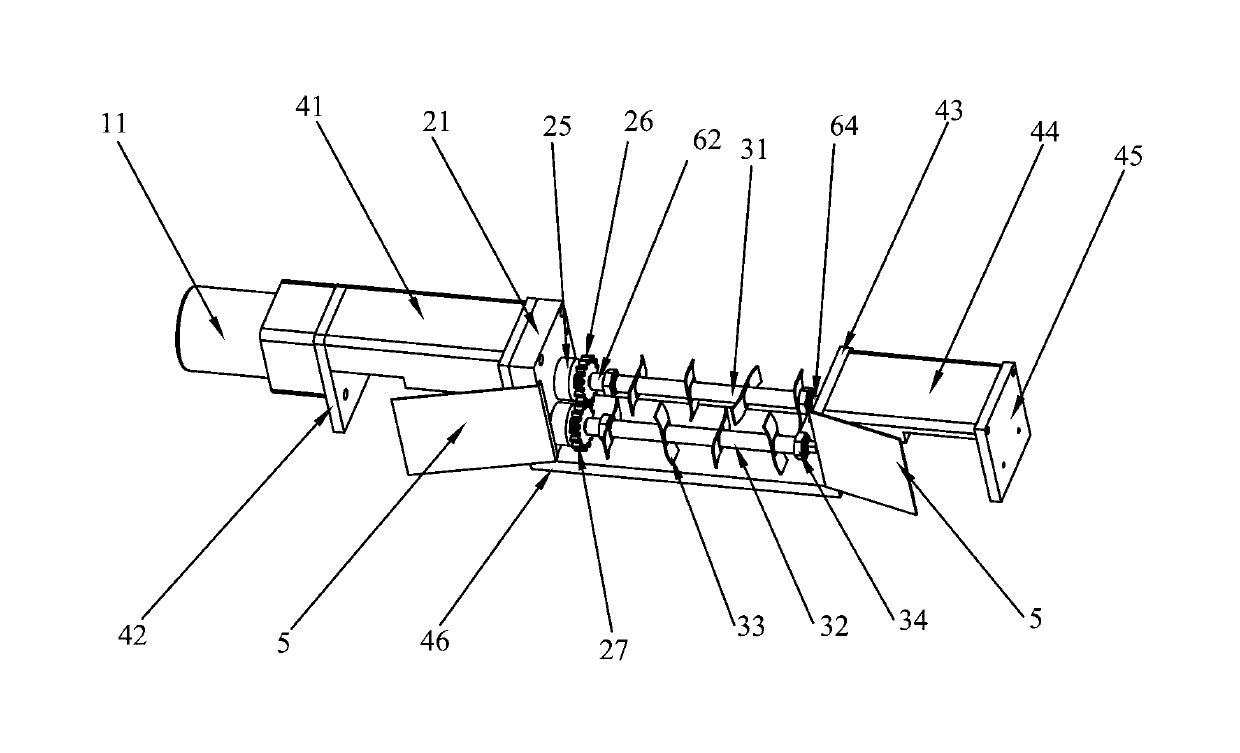

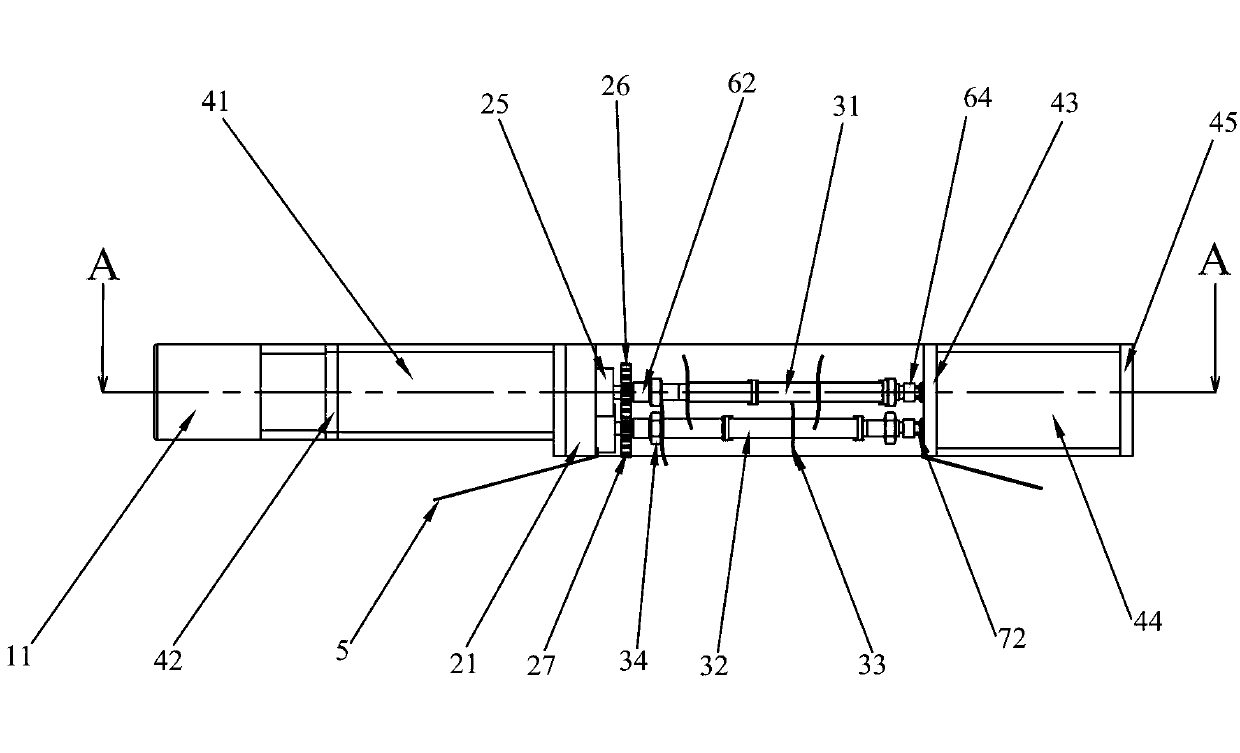

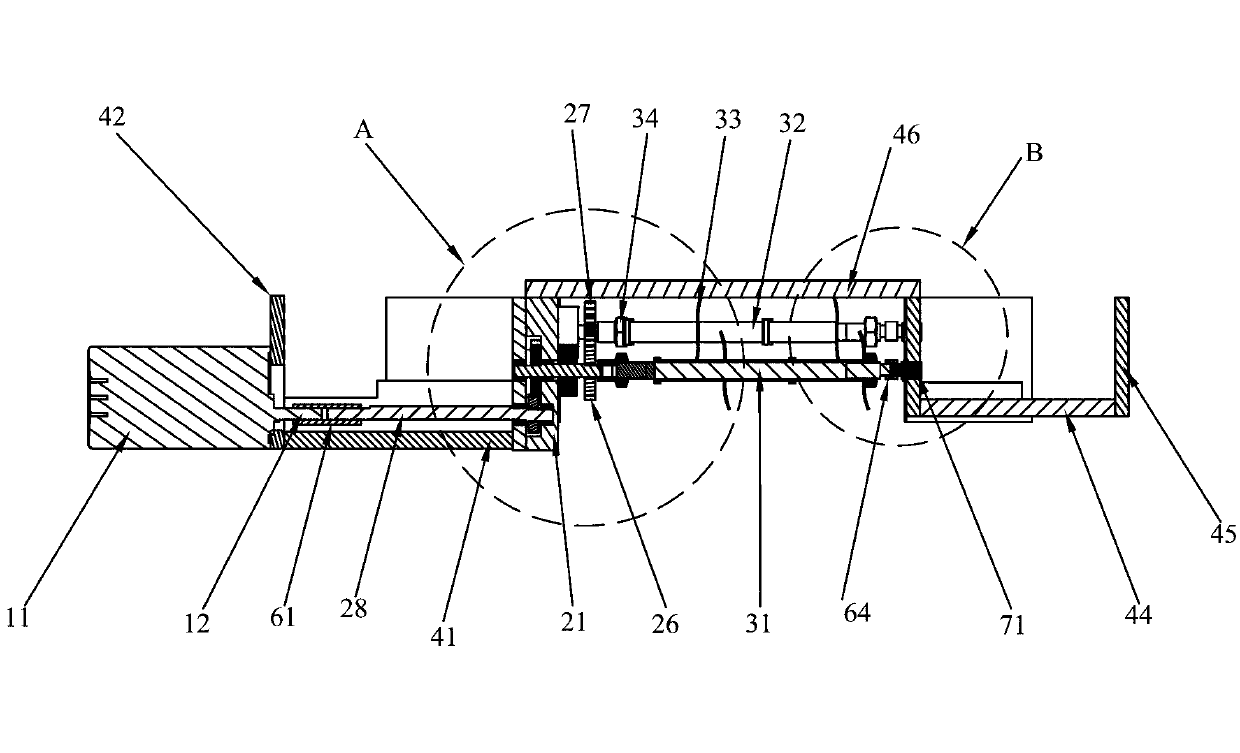

[0034] see Figure 1-Figure 5 It shows a preferred embodiment of the mixer used in the mixing method disclosed in the present invention, including a power assembly, a transmission assembly, a stirring assembly and a supporting assembly.

[0035] The power assembly includes a motor body 11 and a motor shaft 12 .

[0036] The transmission assembly includes an input shaft 28, a closed transmission box 21 (with the side wall of the transmission box 21 close to the stirring assembly as the base plate), an output shaft 24, a driven wheel fixed shaft 29, a driving wheel 26, a driven wheel 27, and a first positioning column 25 , the second positioning column.

[0037] The stirring assembly includes a main stirring shaft 31 and an auxiliary stirring shaft 32 arranged up and down, and stirring blades 33 fixed on the main stirring shaft 31 and the auxiliary stirring shaft 32 at the same time.

[0038] The supporting assembly includes a first bracket 41 , a first limiting plate 42 , a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com