A paint bucket for foundry sand core

A paint bucket and foundry sand technology, which is applied to casting molding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of dip coating thickness change, paint concentration reduction, and labor intensity, etc., to achieve constant paint concentration, The effect of eliminating downward sedimentation and ensuring the quality of dip coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

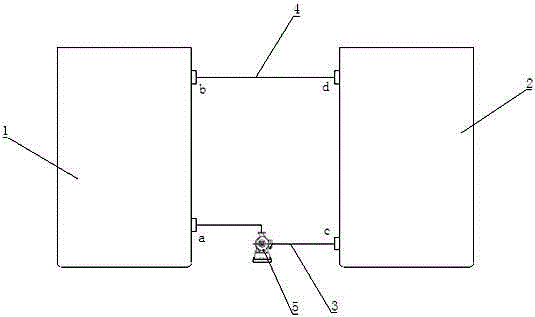

[0010] like figure 1 As shown, it includes a paint tank 1, an auxiliary material tank 2, a circulation pipe 3, an overflow pipe 4 and a circulation pump 5.

[0011] A liquid inlet a is opened at the bottom of the paint bucket 1, and an overflow b is opened on the top side wall;

[0012] A liquid outlet c is opened at the bottom of the auxiliary material barrel 2, and a return opening d is opened at the top, and the height of the return opening d is not higher than that of the overflow opening b.

[0013] The paint bucket 1 and the auxiliary material bucket 2 are placed side by side, the liquid inlet a of the paint bucket 1 is connected with the liquid outlet c of the auxiliary material bucket 2 through the circulation pipe 3, and the circulation pump 5 is installed on the circulation pipe 3, and the overflow of the paint bucket 1 The port b communicates with the return port d of the auxiliary barrel 2 through the overflow pipe 4 .

[0014] A liquid level gauge is installed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com