Milling Tooling for Fungus Root Blades of Steam Turbine

A milling tooling and fungus-shaped technology, which is applied in positioning devices, milling machine equipment, manufacturing tools, etc., can solve the problems of no steam turbine fungal-shaped blade root blade milling tooling, high machining dimensional accuracy requirements, and can not exceed 0.03mm, etc. Simple, ensure consistent processing, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

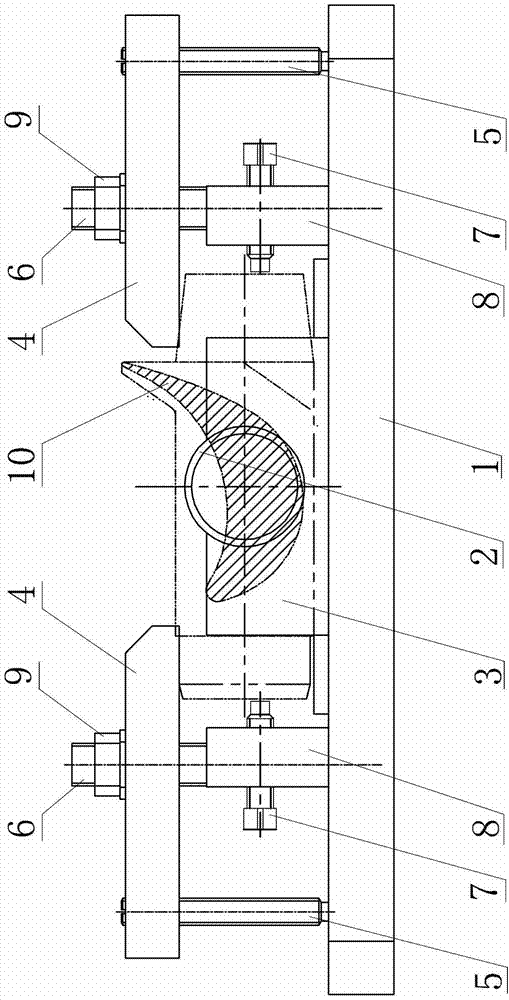

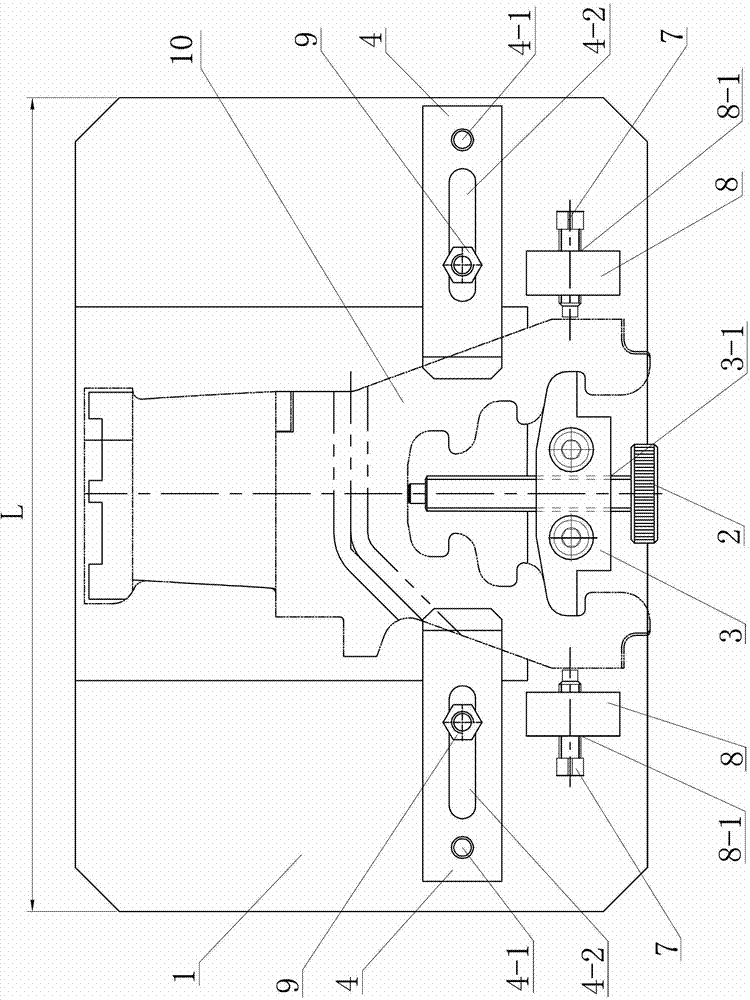

[0008] Specific implementation mode one: combine Figure 1 ~ Figure 3 Explain that the milling tooling of the steam turbine fungus root blade in this embodiment includes a bottom plate 1, a screw rod 2, a positioning block 3, two pressure plates 4, two support screws 5, two adjusting studs 6, and two threaded ejector rods 7 , two ejector rod bearings 8 and two nuts 9, the base plate is a rectangular base plate, the base plate 1 is horizontally arranged, the positioning block 3 is vertically fixed in the middle of one end of the upper end face in the width direction of the base plate 1, and the center of the end face of the positioning block 3 A positioning threaded hole 3-1 is processed, and the axial direction of the positioning threaded hole 3-1 is set perpendicular to the side wall of the one end of the bottom plate 1, and one end of the plate surface of the pressure plate 4 is processed with a first threaded hole 4 along the thickness direction of the pressure plate 4 -1, ...

specific Embodiment approach 2

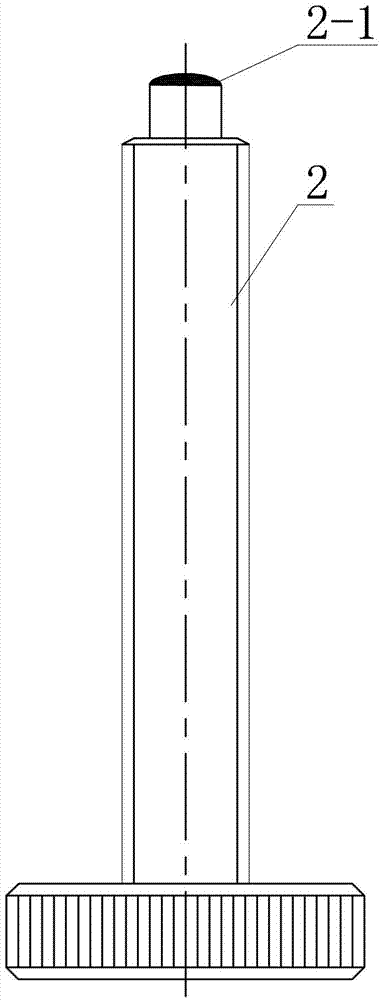

[0009] Specific implementation mode two: combination image 3 To illustrate, the end of the screw 2 in this embodiment is provided with a rubber head 2-1. Such setting makes the cooperation between the screw rod 2 and the mushroom-shaped leaf root 10 more closely, and the positioning effect is better. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 2 Note that the length L of the bottom plate 1 of this embodiment is 300 mm. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0011] Working principle: After the milling tool of the present invention is assembled, the mushroom-shaped root blade 10 to be processed is clamped on the milling tool, and then the milling tool is clamped on a horizontal milling machine for milling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com