Cutting and detection method of full-automatic surface mount tomography (SMT) template cutting and detection integrated system

A detection method and fully automatic technology, applied in welding equipment, laser welding equipment, metal processing equipment and other directions, can solve the problems of low detection efficiency and accuracy, unreliable SMT template, etc., to improve detection efficiency and accuracy, The effect of saving production cost and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A cutting and testing method of an integrated automatic SMT template cutting and testing system comprises the following steps:

[0031] a) The CCD linear scanning component moves to the cutting area in the X and Y directions, and to the scanning position, while the upper beam moves to the non-cutting area;

[0032] b) Press down on the light box above the beam, clamp the cut steel sheet with the upper glass surface of the CCD linear scanning component below, and enter the scanning state for scanning detection;

[0033] c) The cutting and scanning files, position, direction, front and back judgment work is automatically completed by the main control computer;

[0034] d) After scanning, the light box moves up, and the CCD scanning component moves down. After the cutting is completed, the waste vacuum device automatically exits the machine to clean up the waste;

[0035] e) After the waste dust suction device cleans up the waste residue, it returns to the main body of th...

Embodiment 2

[0041] A cutting and detection method of a fully automatic SMT template cutting and detection integrated system, the steps of which are the same as in Example 1.

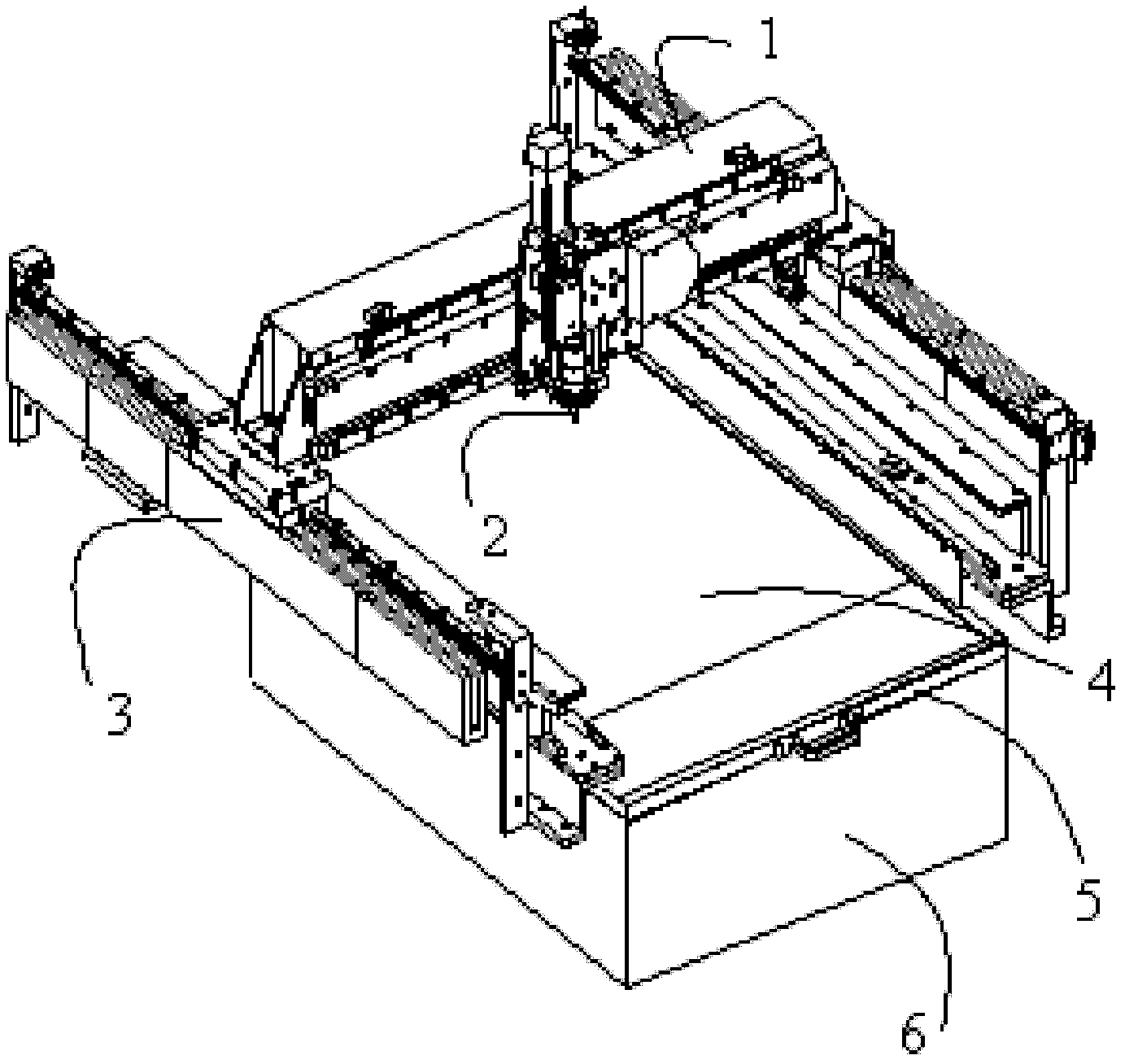

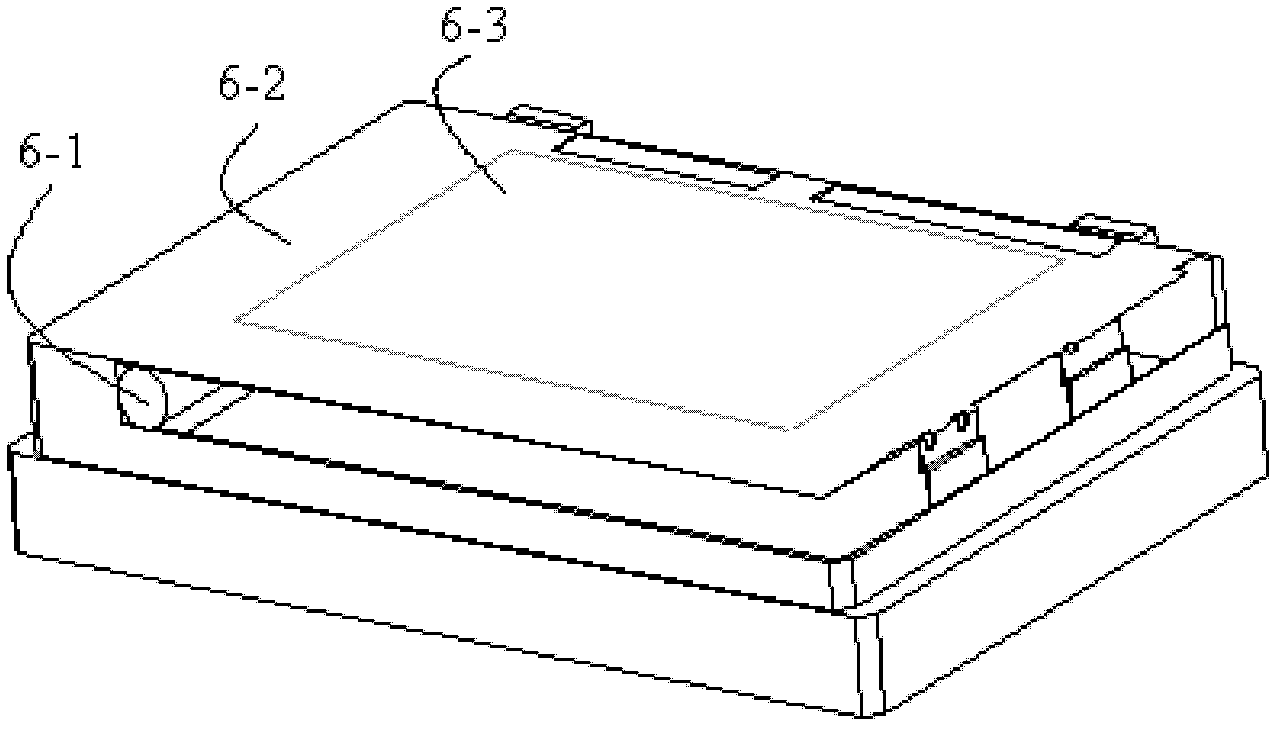

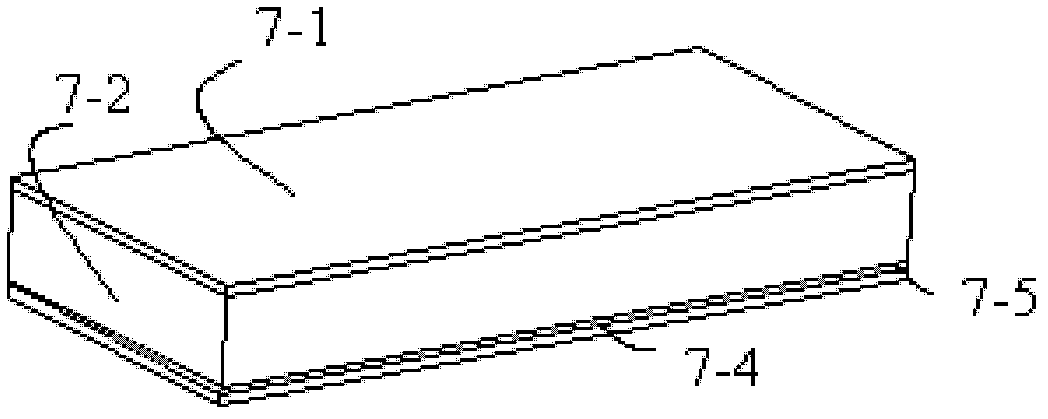

[0042] Fully automatic SMT template cutting and testing integrated system, including cutting head, X-direction moving beam, Y-direction moving beam, steel sheet stretching mechanism, waste dust suction part, CCD linear scanning component and main control computer, the cutting head is located in X direction On the moving beam, the waste dust suction part is located under the steel sheet stretching mechanism, the CCD linear scanning component is located under the waste dust suction device, a light box is installed above the X-direction moving beam, the CCD linear scanning component has a glass surface, and the main computer controls the cutting head. , The movement of CCD linear scanning components. Three-dimensional light box image 3 As shown, 7-1 is a light box cover plate; 7-2 is a longitudinal support plate; 7-3...

Embodiment 3

[0046] A cutting and testing method of an integrated automatic SMT template cutting and testing system comprises the following steps:

[0047] a) The CCD linear scanning component moves to the cutting area in the X and Y directions, and to the scanning position, while the upper beam moves to the non-cutting area;

[0048] b) Press down on the light box above the beam, clamp the cut steel sheet with the upper glass surface of the CCD linear scanning component below, and enter the scanning state for scanning detection;

[0049] c) The cutting and scanning files, position, direction, front and back judgment work is automatically completed by the main control computer;

[0050] d) After scanning, the light box moves up, and the CCD scanning component moves down. After the cutting is completed, the waste vacuum device automatically exits the machine to clean up the waste;

[0051] e) After the waste dust suction device cleans up the waste residue, it returns to the main body of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com