Processing method for repairing blade tip mechanism of wind turbine generator set

A process method and technology for wind turbines, applied in the field of wind power, can solve problems such as deformation or welding of guide boxes, loss of power generation of wind turbines, etc., and achieve the effects of low maintenance cost, enhanced strength, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

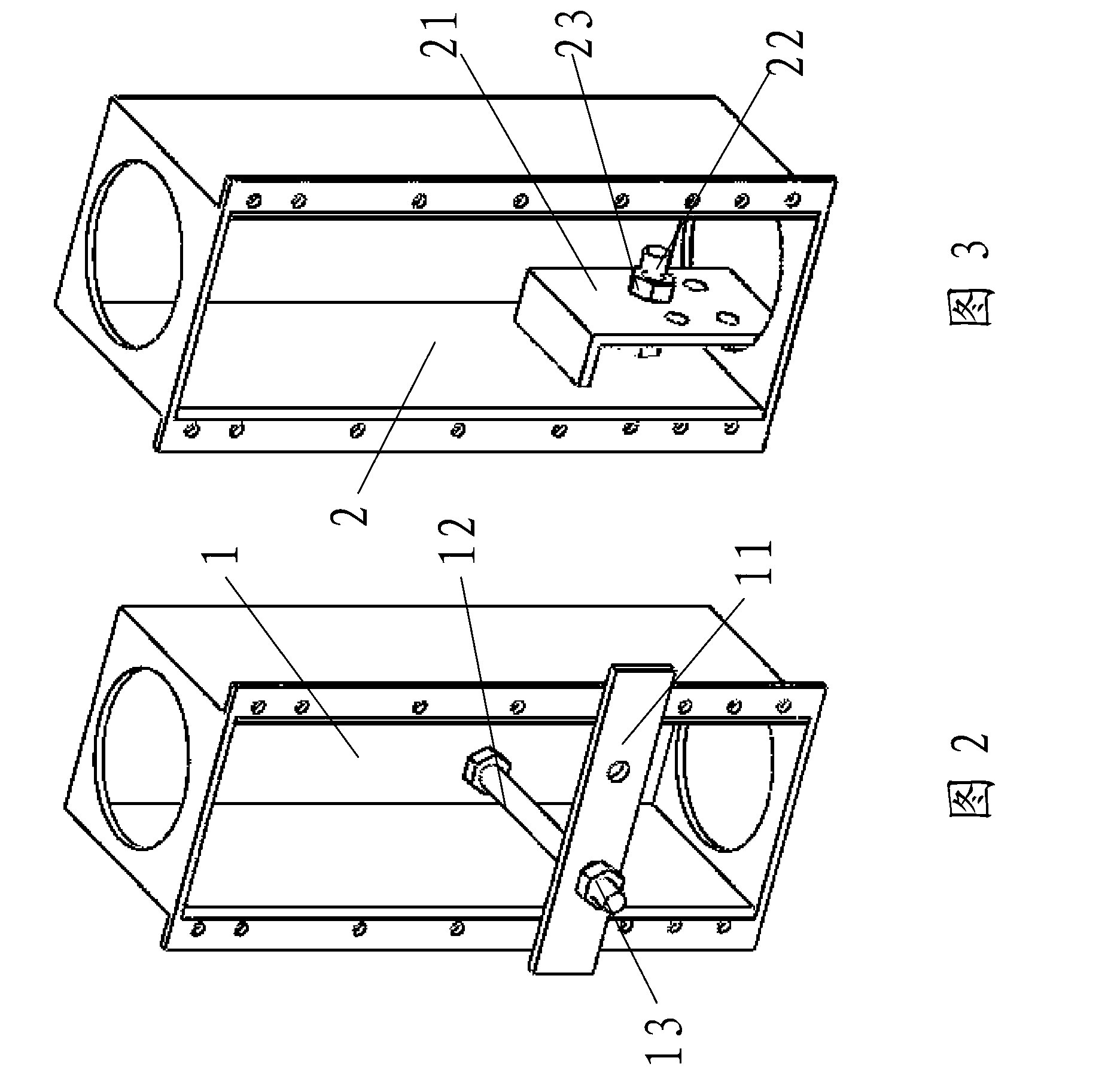

[0022] The invention corrects and welds the deformed or unwelded guide box, and then fills the back of the guide box so that the guide box and the web of the box girder become a whole, thereby achieving the purpose of repairing and strengthening the guide box, and avoiding the blades from running During the process, the guide box is deformed or the welding is opened.

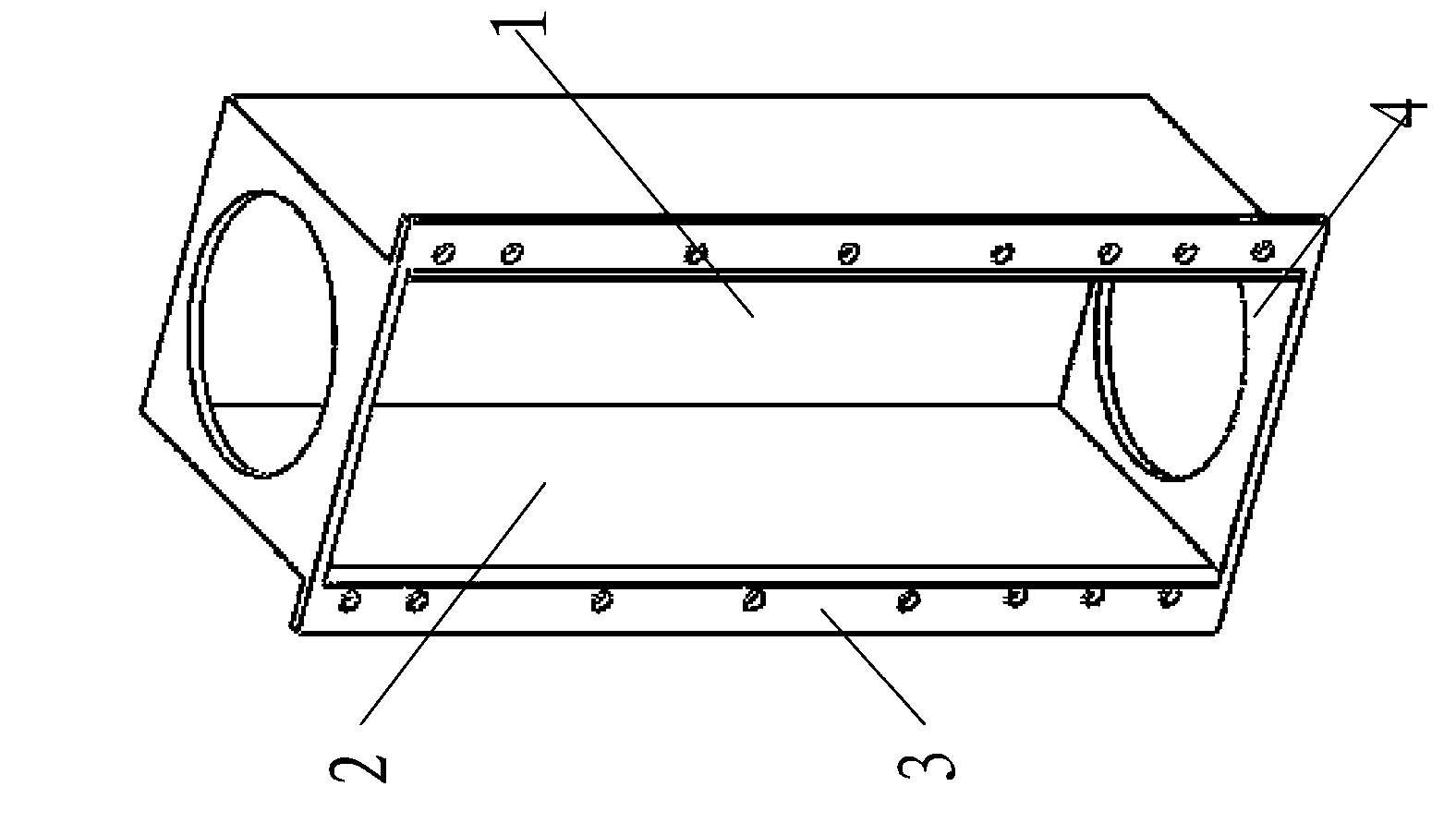

[0023] see figure 1 As shown, the existing common guide box of the tip brake system is a rectangular box formed by splicing three 4mm thick stainless steel plates, including a back plate 1 , a base 3 and a pair of side plates 2 . During the normal retraction process of the blade tip, the guide box achieves the purpose of positioning the blade tip by positioning the guide sleeve. During this process, the guide box needs to overcome the resistance during the rotation of the blade tip.

[0024] The specific steps of the process for repairing the blade tip mechanism of the wind turbine in the present invention are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com