Stainless steel composite anti-skid plate

A skid plate, stainless steel technology, applied to the hull deck, floor, hull parts, etc., can solve the problems of accelerated aging of the skid plate, easy entry of the skid plate, loss of the anti-slip effect of the anti-skid plate, etc., achieving long service life and good anti-slip effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

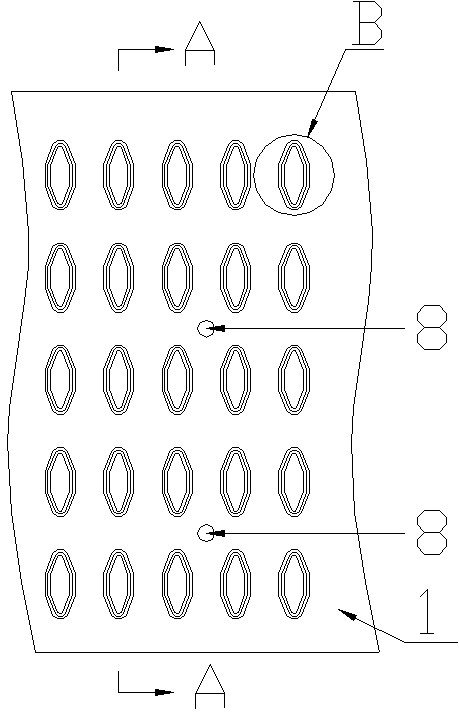

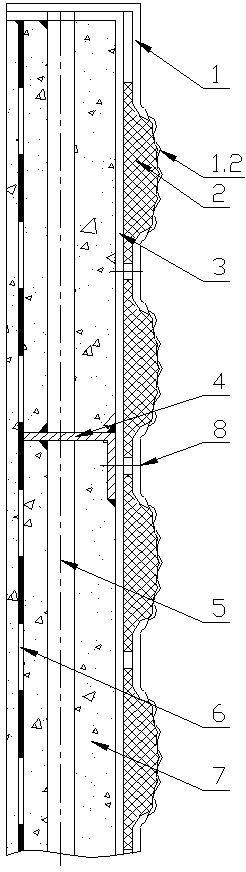

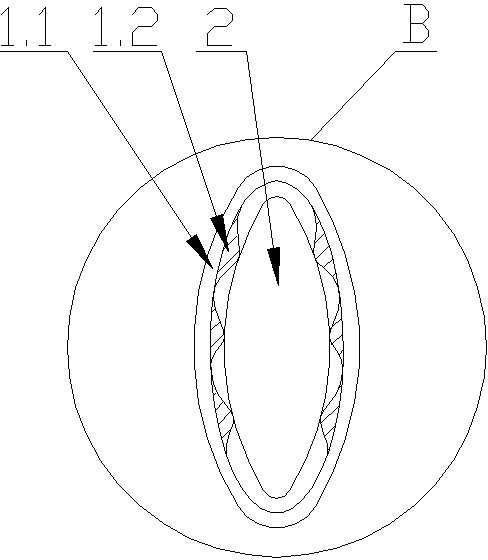

[0029] see Figure 1-4 , the present invention relates to a stainless steel composite anti-skid plate, which includes a base plate 1, rubber nails 2, sealing plate 3 and bolts 8 (see figure 2 ), the substrate 1 is provided with holes 1.1 arranged in an array (see figure 1 ), the hole wall of the hole 1.1 is provided with serrations 1.2 (see image 3 ), the rubber nail 2 includes a step part 2.1 and a pad part 2.2, the step part 2.1 is embedded in the hole 1.1, the pad part 2.2 is attached to the back side of the substrate 1, and the back side of the pad part 2.2 is sealed with a sealing plate 3, so The sealing plate 3 is fixed by the bolt 8 and the base plate 1, the back of the sealing plate 3 is provided with reinforcing ribs 4 and round steel 5, the round steel 5 passes through the reinforcing rib 4, and the round steel 5 and the reinforcing rib 4 are criss-crossed Arrangement, the back side of the sealing plate 3 with the reinforcing rib 4 and the round steel 5 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com