Automatic plate conveying machine

A plate feeding machine and automatic technology, which is applied in the direction of conveyor objects, object destacking, transportation and packaging, etc., can solve the problems of high production cost, high labor intensity, low conveying efficiency, etc., and achieve high efficiency and remarkable energy saving characteristics , good promotion value and market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

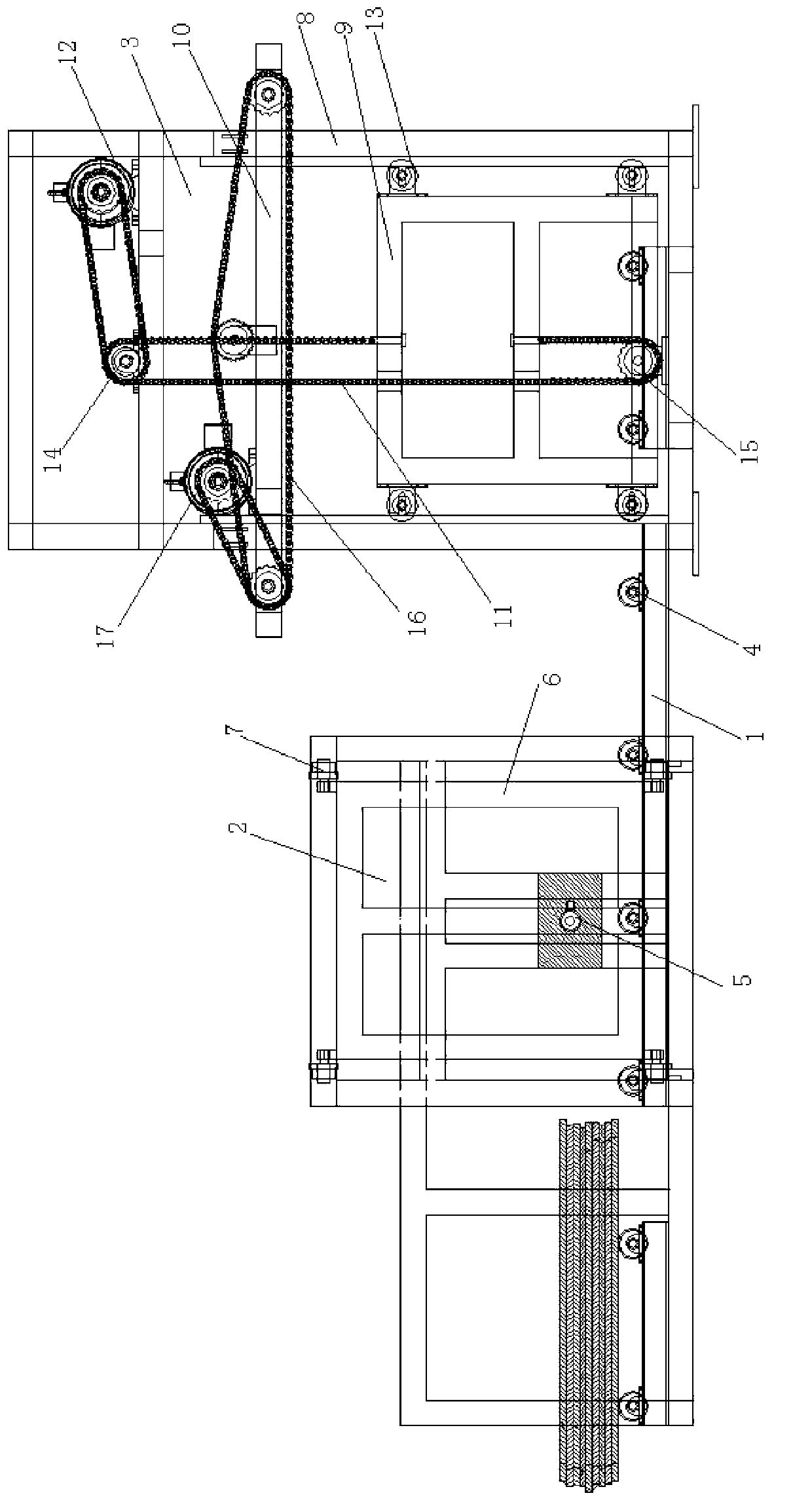

[0017] Referring to the accompanying drawings, an automatic board feeding machine includes a conveying track 1, a plate extruding device 2 and a plate feeding device 3, a roller 4 is arranged on the upper end of the conveying track 1, and the conveying track 1 passes through the extruding device 2 and the plate feeding device in turn 3. At the bottom, the extruding device 2 includes a cubic frame 4 and a hydraulic cylinder 5 arranged inside the cubic frame. The top of the hydraulic cylinder 5 is connected with an extruding crane 6, and the upper and lower ends of the extruding crane 6 are connected with the cubic frame. Guide wheel 7; plate feeding device 3 includes main frame 8, elevator 9, upper limit plate delivery 10, transmission chain 11 and lifting motor 12, elevator 9 is placed inside main frame 8, and its side passes through guide wheel 13 and main frame 8 Vertical sliding contact, a lifting motor 12 is installed on the top of the main frame, and the lifting motor 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com