Desulfurization wastewater dechlorination treatment method and desulfurization wastewater treatment equipment

A desulfurization wastewater and treatment method technology, applied in water/sewage treatment equipment, water/sewage treatment, flotation water/sewage treatment, etc., can solve problems such as difficult treatment, failure of electric dust removal, complicated system maintenance, etc. Convenient and simple maintenance, large saturated adsorption capacity, and convenient system connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

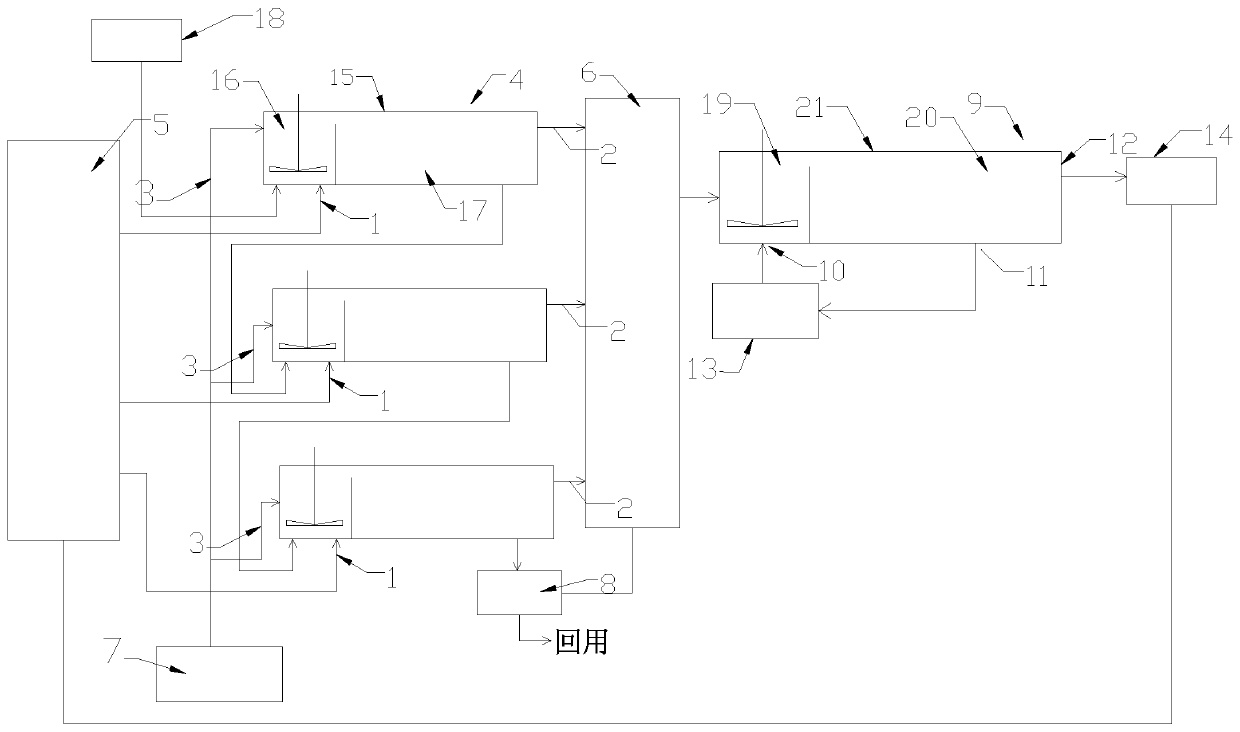

[0052] As shown in the figure, the dechlorination treatment method of desulfurization wastewater in this embodiment is used as a basic treatment method, and it includes the following steps:

[0053] A. First add acid to the desulfurization waste water taken from the hydrocyclone or from the triple box to adjust the pH value to 0.5-4, and then make it enter the mixing chamber of the primary dechlorination reactor and mix it with the liquid resin. After stirring for 1-10 minutes, it enters the corresponding separation chamber in this step, that is to say, before the desulfurization wastewater enters the stirring chamber of the primary dechlorination reactor, the desulfurization wastewater is pretreated by a triple box. It is recommended to remove calcium ions in the pretreatment , adding sodium carbonate to the reaction tank of the triple box to remove most of the calcium ions in the wastewater, and then take water from the clean water tank after the triple box treatment, wherein...

Embodiment 2

[0060] This embodiment is a technical solution further improved on the basis of Embodiment 1, which can achieve better processing functions. Specifically, the liquid resin entering the liquid resin buffer tank continues to enter the resin regeneration process section, The regeneration process section is also an important procedure to realize the zero-discharge industrialization of desulfurization wastewater. While the liquid resin entering the liquid resin buffer tank continues to enter the regeneration reactor mixing chamber of the resin regeneration process section, regenerated resin is added to the regeneration reactor mixing chamber. The medicament is stirred and mixed, and the chloride ions in the liquid resin are released into the regenerated medicament, and the chloride ions react with the regenerated medicament to form a chloride salt solution. After mixing and stirring, the mixture of the chloride salt solution and the liquid resin enters the process section. In the se...

Embodiment 3

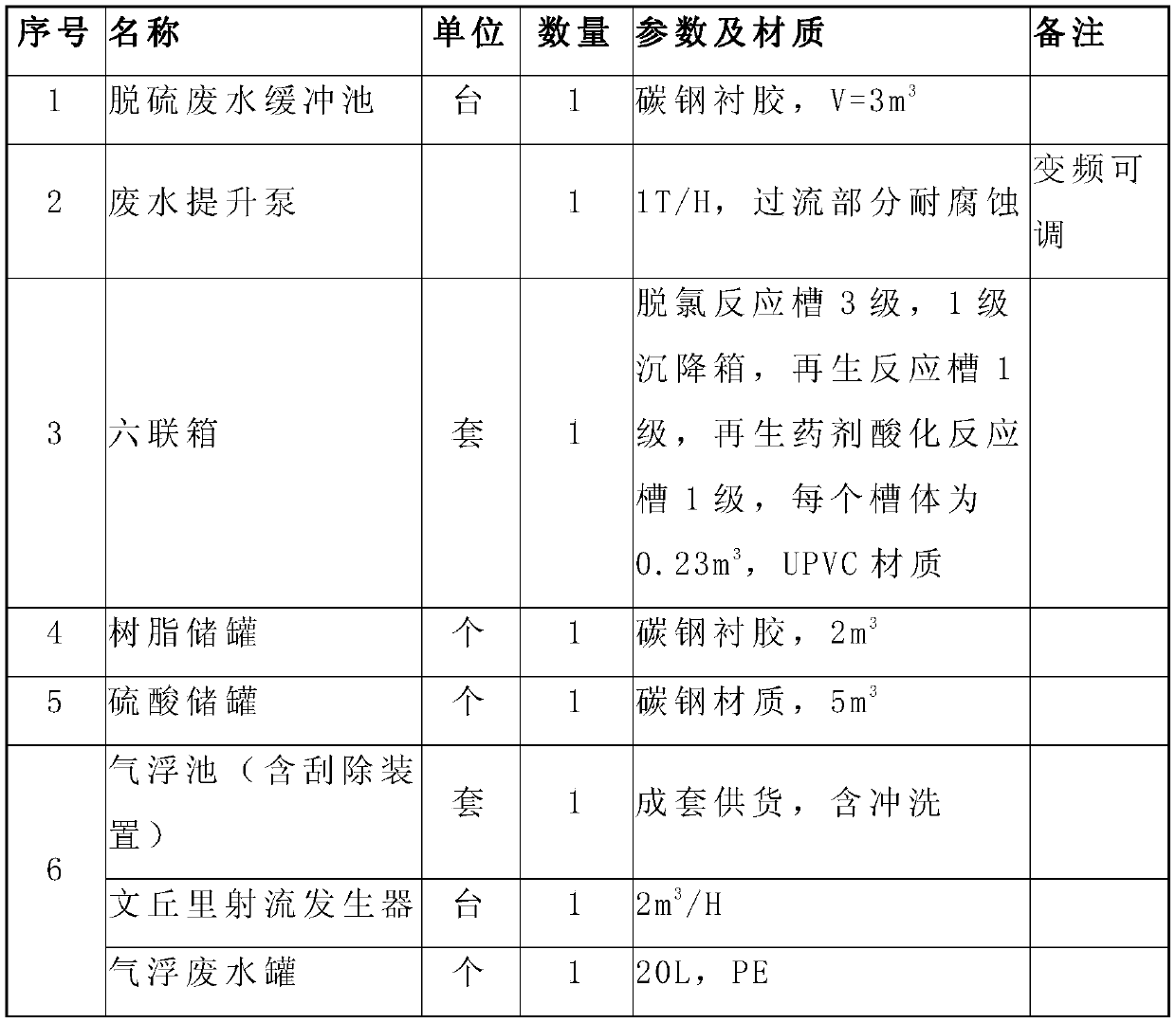

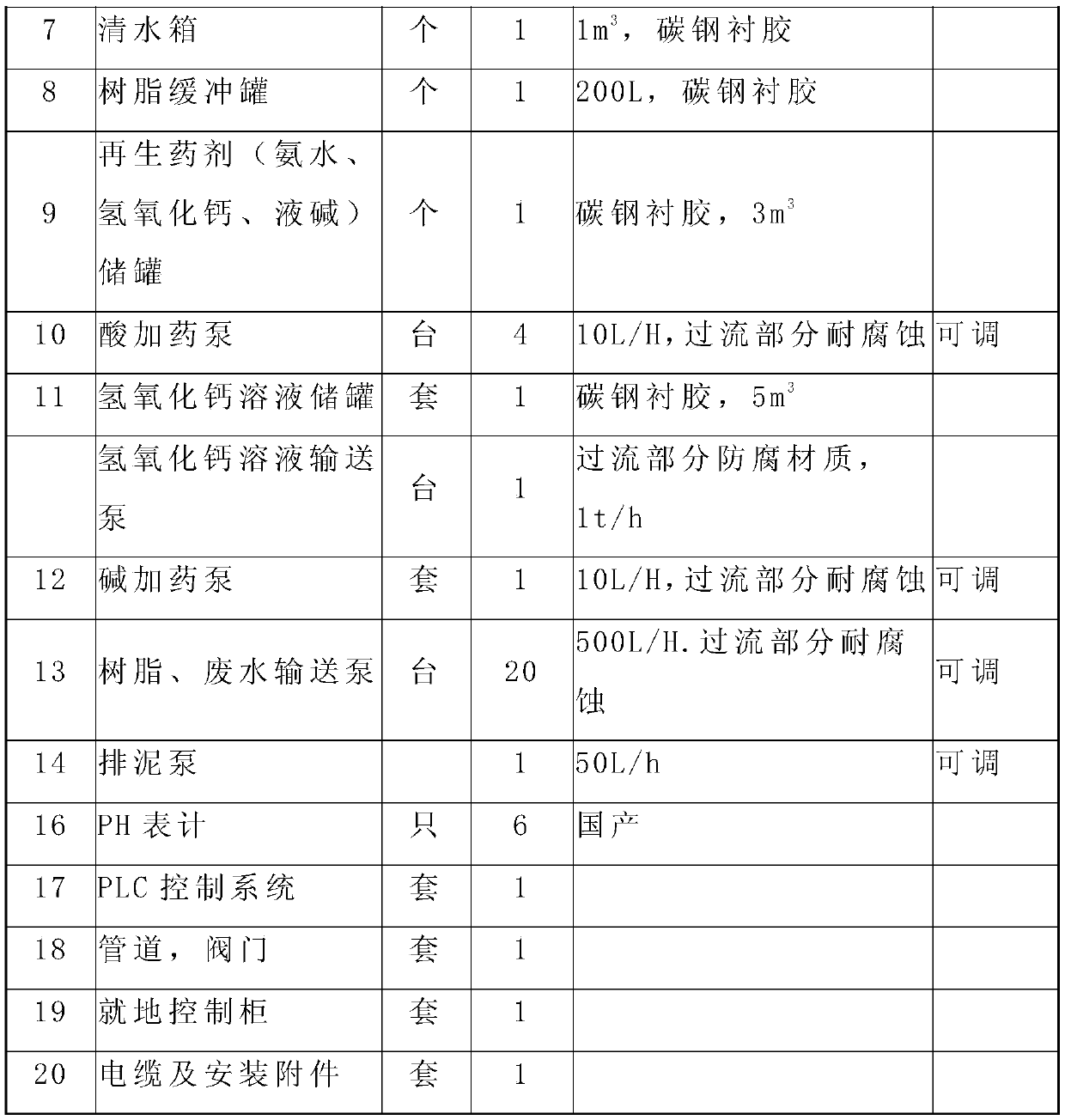

[0064] The desulfurization wastewater treatment equipment of the present embodiment comprises multistage dechlorination reactors 4 connected in series with resin inlet 1, resin outlet 2 and sulfuric acid inlet 3 (collectively referred to as connection port), said multistage dechlorination reactor 4 It is composed of N-level dechlorination reactors such as the first-level dechlorination reactor, the second-level dechlorination reactor, the third-level dechlorination reactor, and the fourth-level dechlorination reactor. Only the waste water is fed to the first-level dechlorination reactor The pump is connected with a waste water storage tank 18. In the present embodiment, the dechlorination reactors 4 at all levels include a dechlorination reaction tank 15 and a dechlorination stirring chamber 16 and a dechlorination mixing chamber 16 separated by partitions arranged in the dechlorination reaction tank. The separation chamber 17, the dechlorination stirring chamber 16 of the dech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com