Wet strength agent, paper production technology and paper

A production process and wet strength agent technology, applied in the direction of reinforcing agent addition, etc., can solve the problems of easy decomposition and recycling, unfavorable to the environment, difficult paper, etc., and achieve the effects of recycling, good wet strength, and easy decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

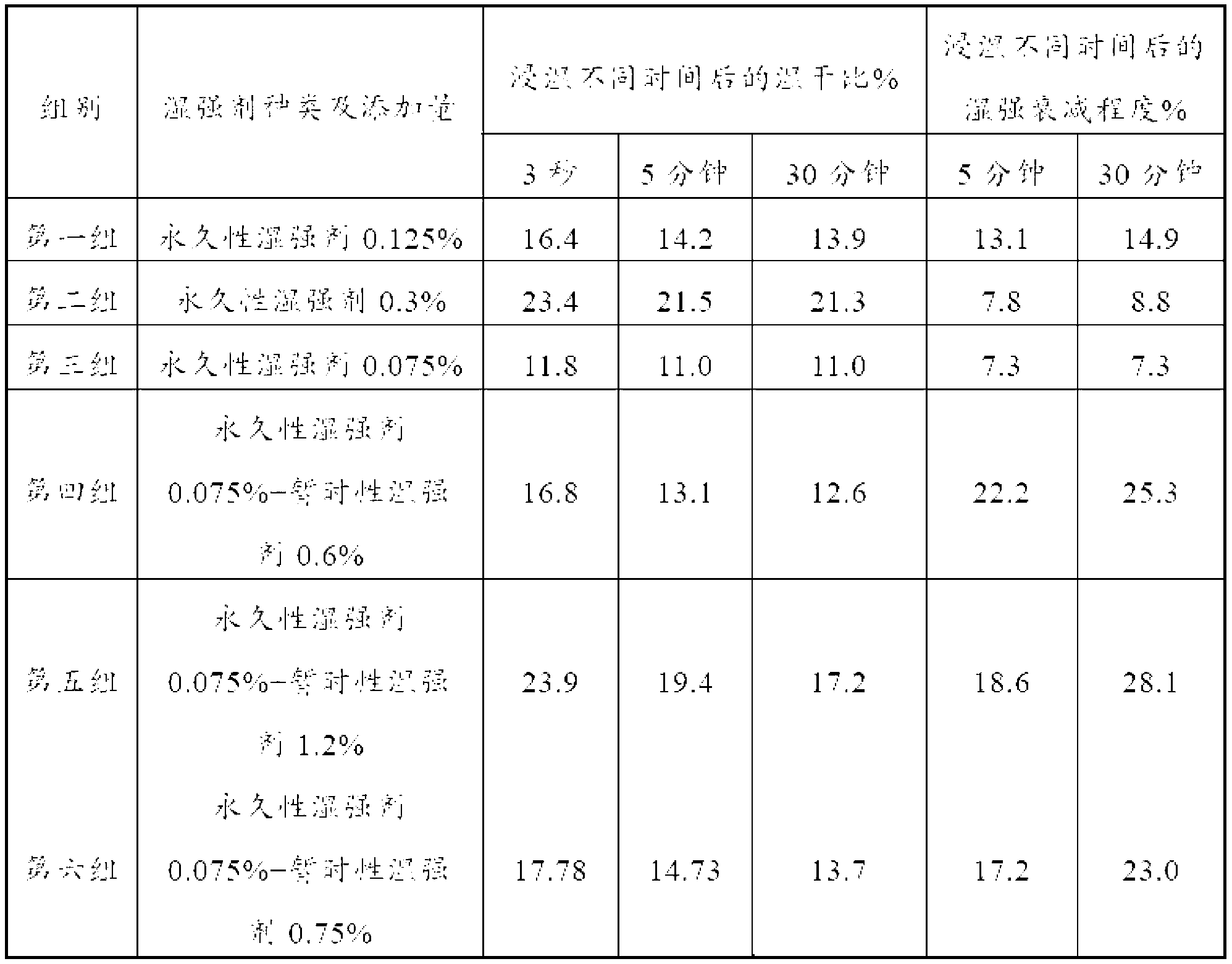

[0010] The embodiment of the present invention provides a wet strength agent, which is mainly composed of a permanent wet strength agent and a temporary wet strength agent, wherein the mass ratio range of the permanent wet strength agent to the temporary wet strength agent is 0.02 to 0.5: 0.2 to 5.

[0011] As is well known to those skilled in the art, the general basis for judging the permanent wet strength agent and temporary wet strength agent involved in the present invention is: compared with the initial wet strength of the paper after wetting, the wet strength of the paper after 10 After 2 seconds to 2 hours, the wet strength agent that loses less than 20% of the wet strength of the paper is a permanent wet strength agent, and after the paper is wet for 10 seconds to 2 hours, the wet strength loss of the paper is greater than or equal to 50%. The strengthening agent is a temporary wet strength agent.

[0012] The permanent wet strength agent mainly includes urea-formald...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com