Light-emitting diode (LED) ball lamp in automatic production

A technology of LED light sources and ball lamps, which is applied to components of lighting devices, semiconductor devices of light-emitting elements, lighting devices, etc., can solve problems such as complex assembly, high production intensity, and low production efficiency, and achieve simple connection and simplified structure , Improve the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

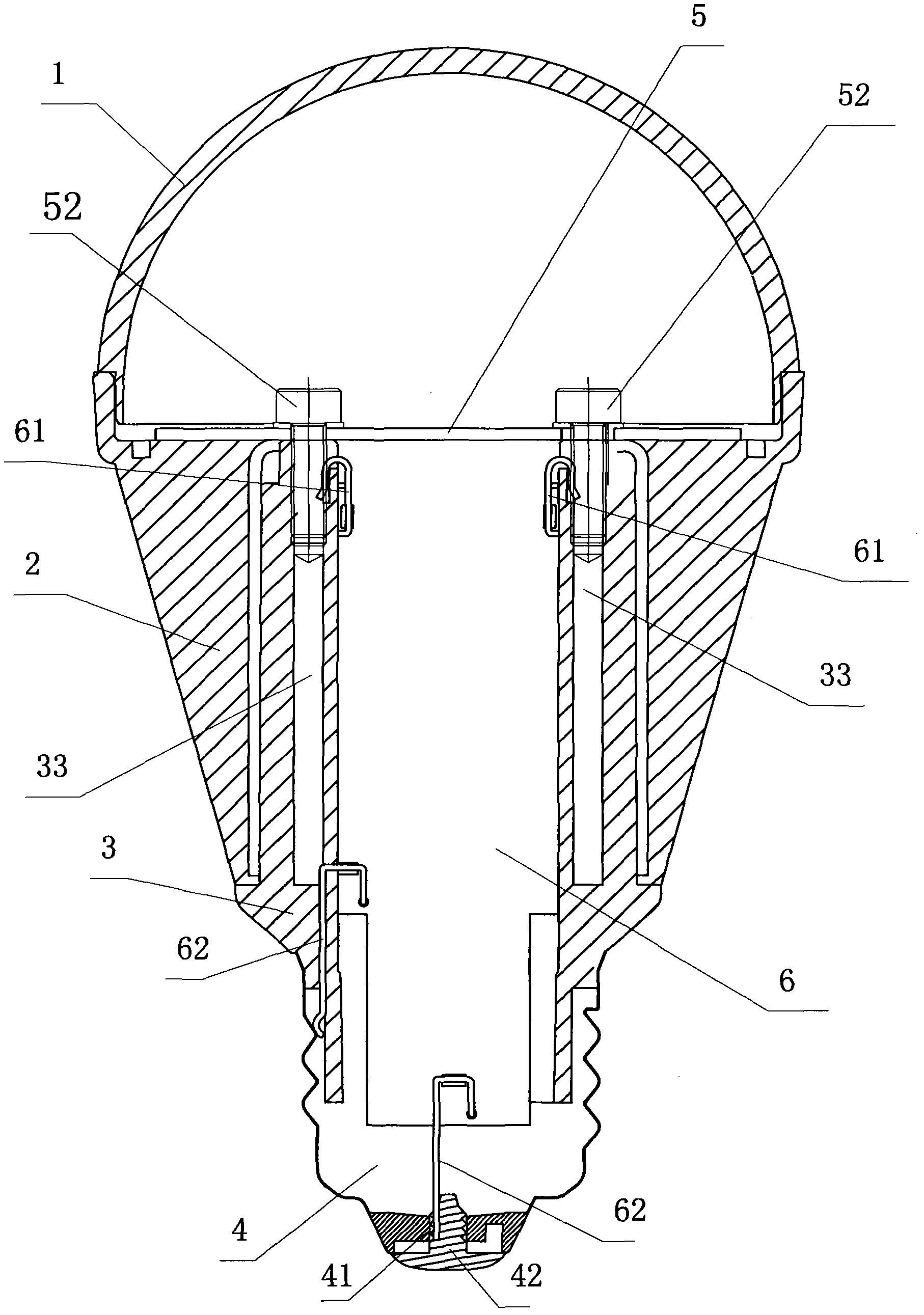

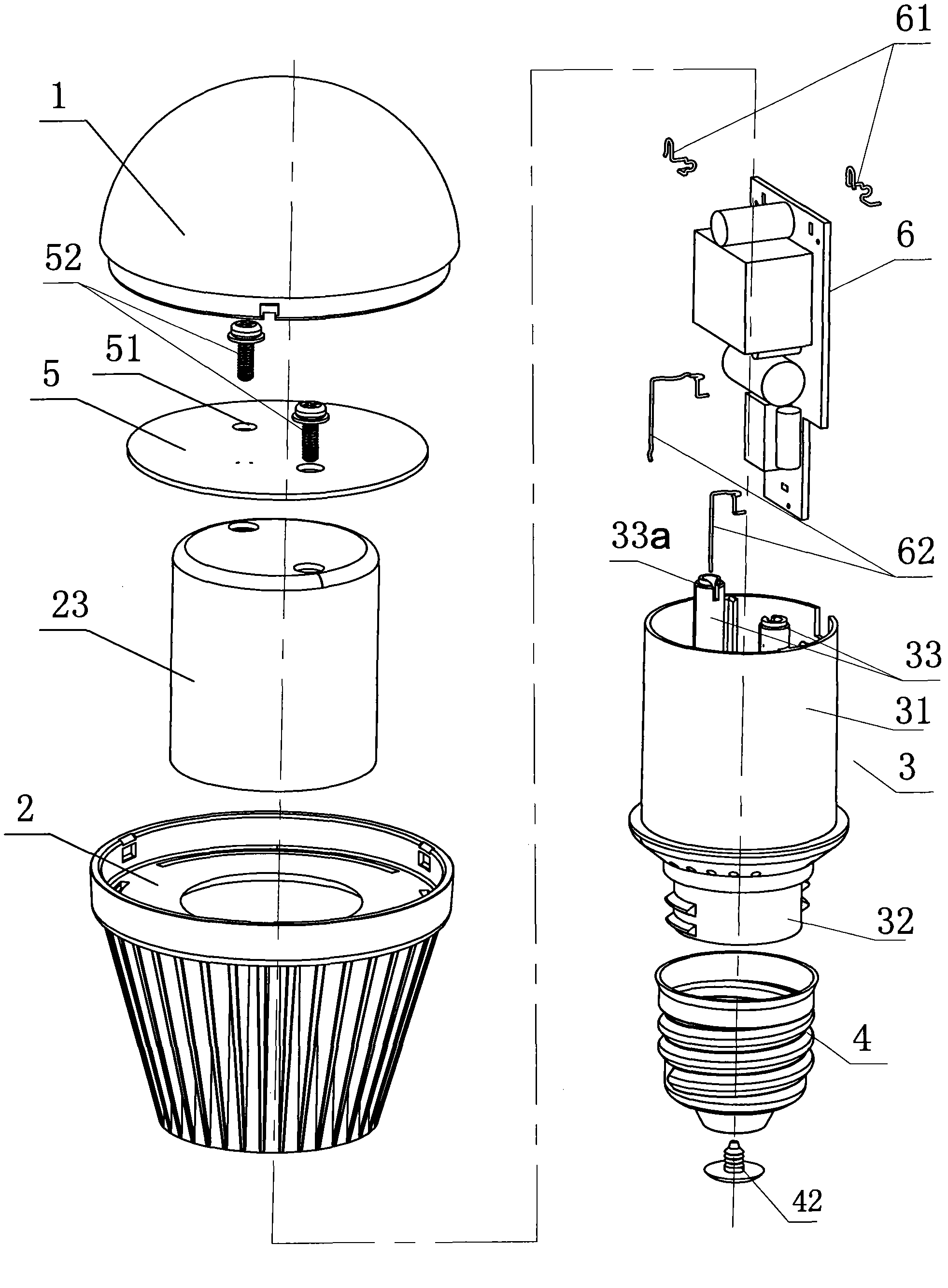

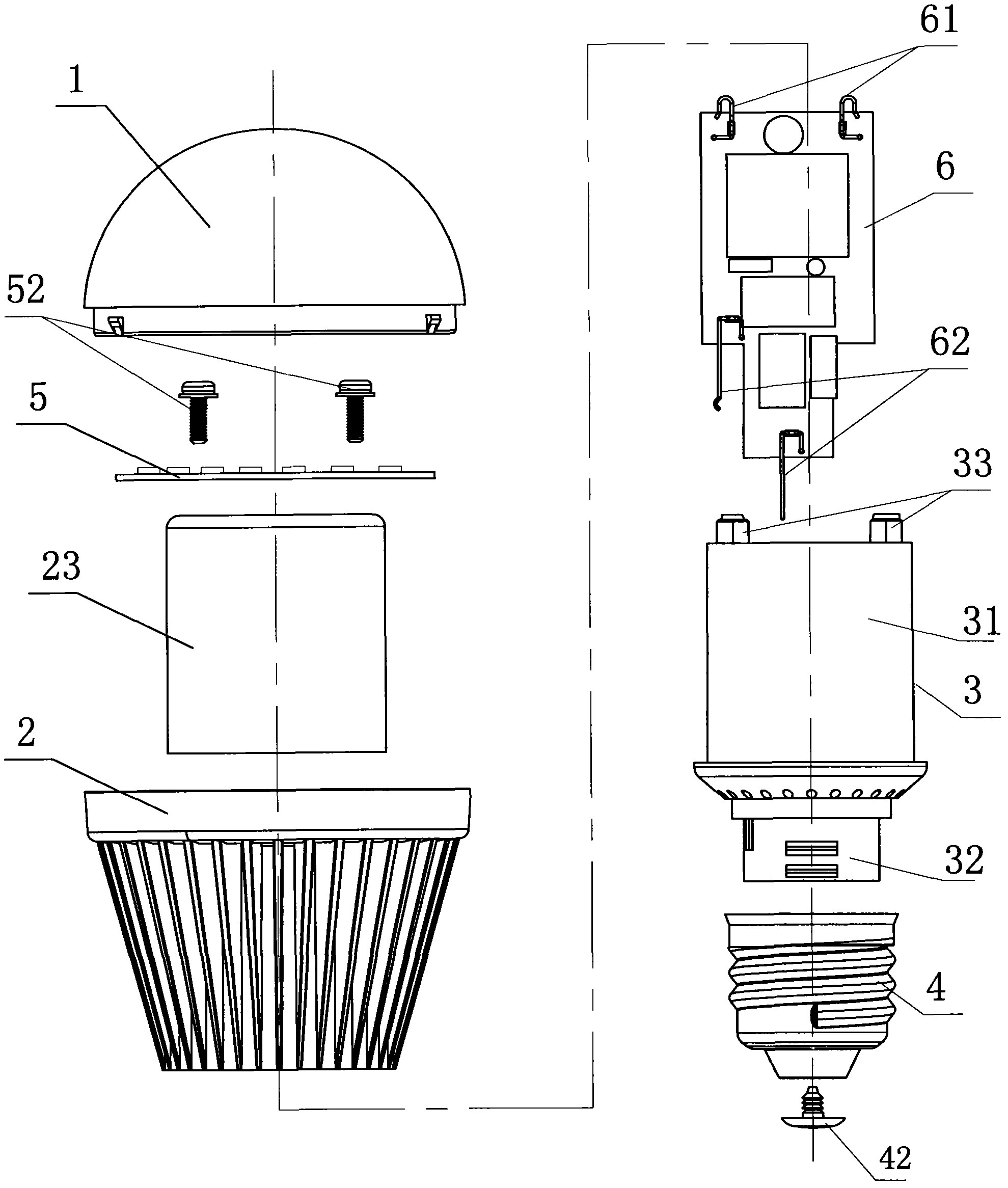

[0052] Such as Figure 1 to Figure 34 Shown: an automatically produced LED ball lamp, including an inner hollow lamp body composed of a lens 1, a heat dissipation lamp cup 2, a connecting seat 3, and a lamp cap 4 connected in sequence, and an LED light source in the lamp body. The LED light source includes a luminous lamp bead Circuit board 5 and power supply circuit board 6, the two sides of power supply circuit board 6 upper part are symmetrically provided with the output connecting line 61 that free end is barb-like extending out of the board surface, middle and lower part are respectively provided with the input that free end is vertically arranged. The connecting line 62, the connecting seat 3 is cylindrical, and includes a barrel body 31 and a connector 32 with a lower neck. Vertical inner space positioning columns 33 are arranged along both sides of the barrel body 31, and the upper ends of the two positioning columns 33 are respectively opened. There is a gap 33a, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com