Material returning fault self-healing control system for circulating fluidized bed boiler

A circulating fluidized bed, fault self-healing technology, used in fluidized bed combustion equipment, fuel burning in a molten state, lighting and heating equipment, etc. problems, to avoid operational errors, improve safety, and achieve the effect of self-healing control of return failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

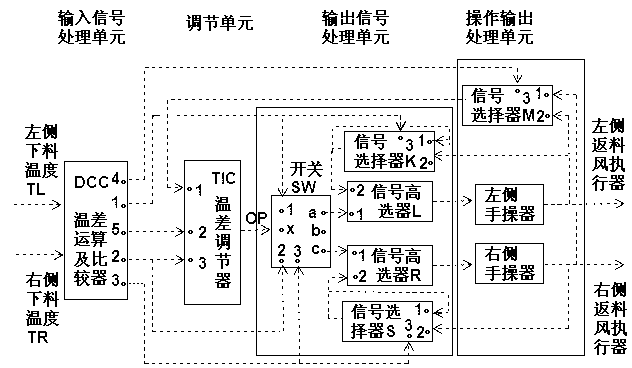

[0020] As shown in the accompanying drawings, a circulating fluidized bed boiler fault self-healing control system proposed by the present invention includes an input signal processing unit, an adjustment unit, an output signal processing unit, an operation output processing unit and a return air actuator.

[0021] input signal processing unit

[0022] The left blanking temperature TL and the right blanking temperature TR are connected to the input terminal of the temperature difference calculation and comparator DCC. The left blanking temperature TL minus the right blanking temperature TR is defined as the temperature difference. The upper limit of the temperature difference ranges from 20°C ~30°C, the lower limit of the temperature difference ranges from -30°C to -20°C, the temperature difference calculation and comparator DCC has 5 output terminals DCC-1, DCC-2, DCC-3, DCC-4, and DCC-5 respectively corresponding to the temperature difference If the temperature difference i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com