Fluid resistance device

A technology of fluid resistance and components, applied in liquid/fluid solid measurement, detecting fluid flow by measuring pressure difference, pipe components, etc., can solve problems such as difficulty in achieving uniform product performance, inability to achieve compactness, time-consuming and labor-intensive, etc. To achieve uniform performance improvement, compact quantity, simple manufacturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

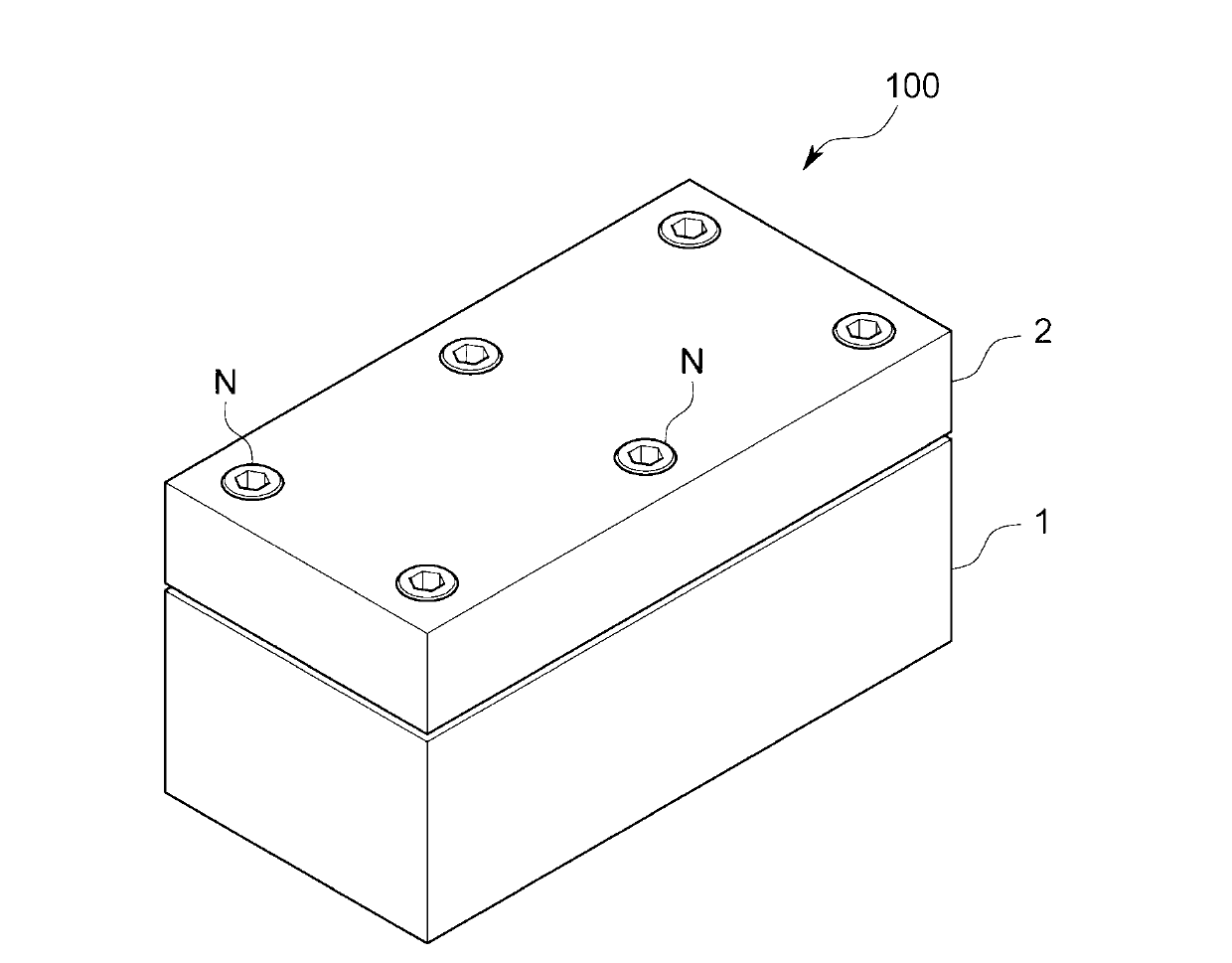

[0045] Next, the fluid resistance member 100 of this embodiment will be described with reference to the drawings.

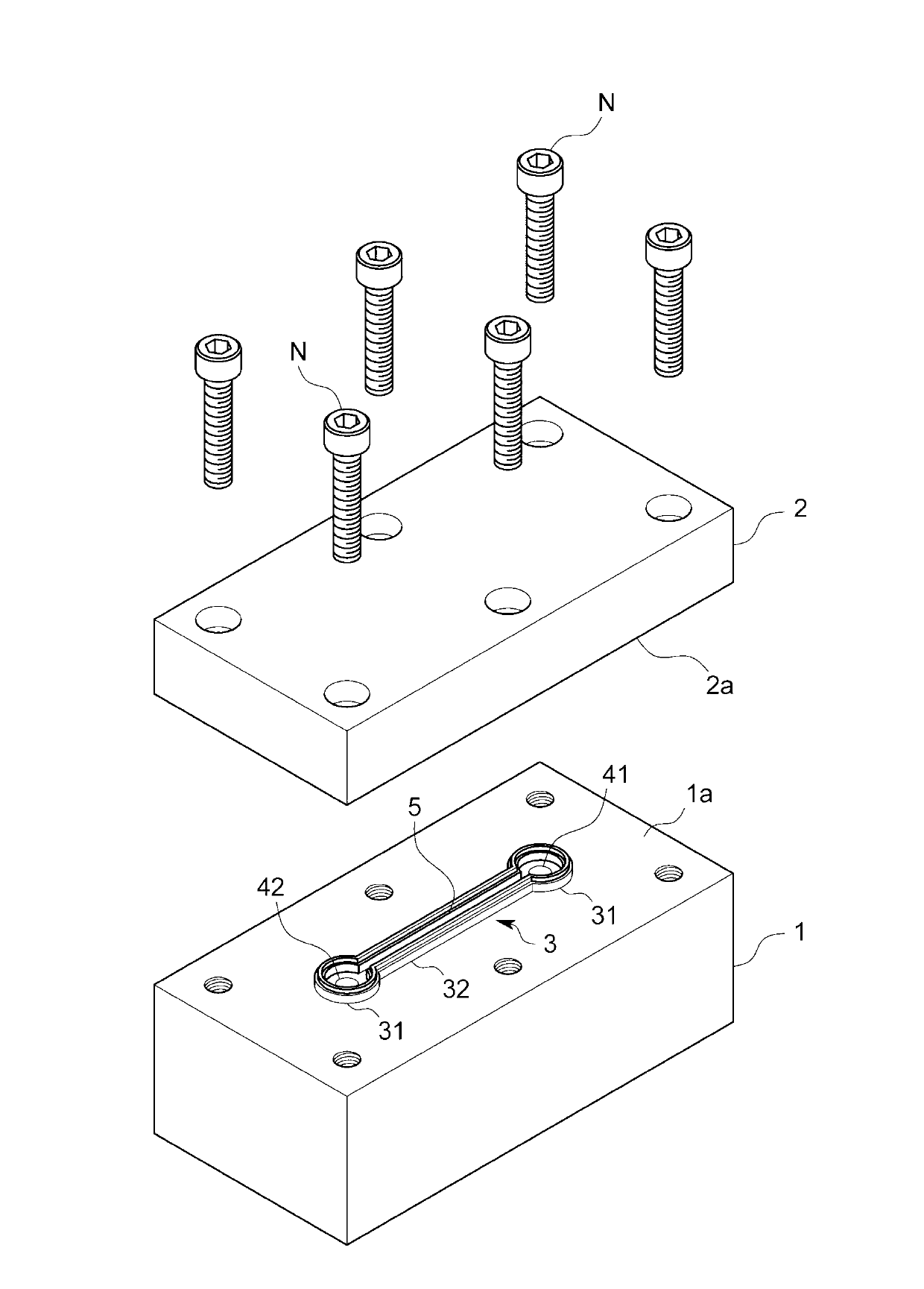

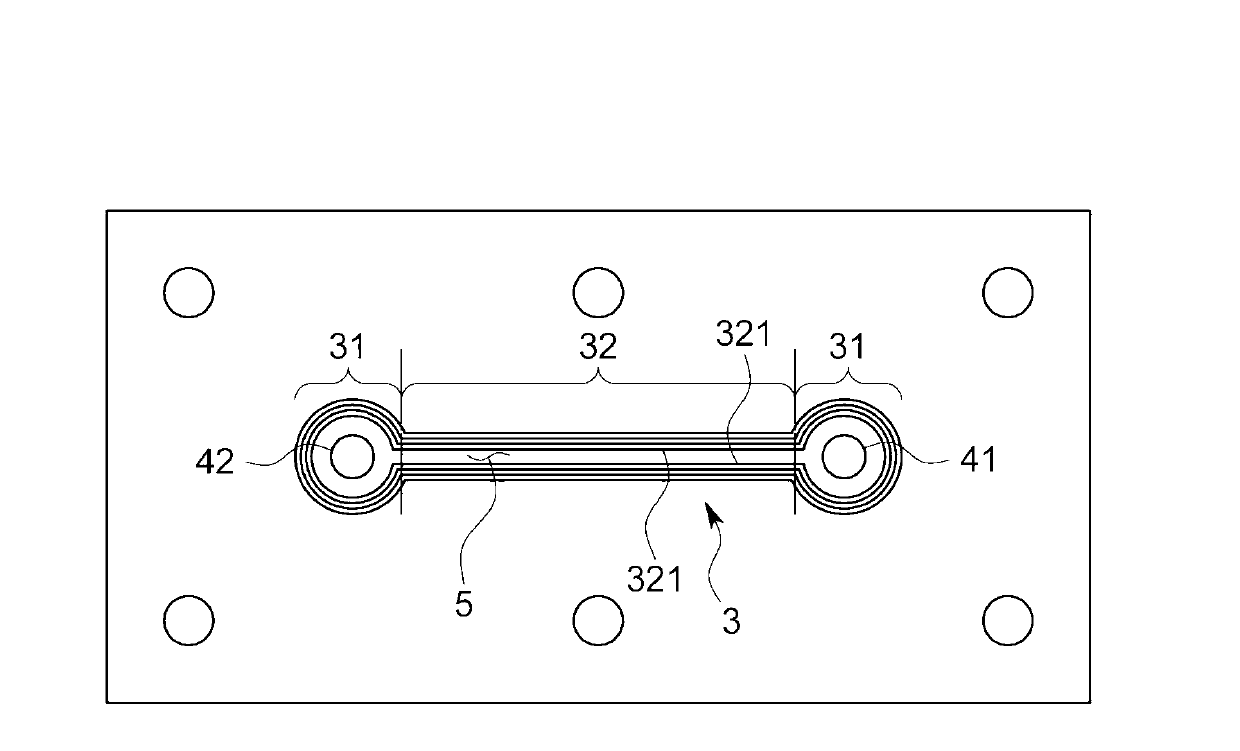

[0046] Such as figure 1 As shown, the fluid resistance component 100 is in the shape of a rectangular parallelepiped as a whole, and constitutes, for example, a part of a flow control device, that is, a part that measures the flow rate by measuring the pressure before and after the fluid resistance component 100 (specifically 3 cc / min or less liquid flow measurement part), in the inside of the fluid resistance component 100, an upstream channel (not shown), a downstream channel (not shown) and a fluid resistance channel 5 for fluid flow are formed, and the fluid resistance The flow channel 5 is connected between the upstream flow channel and the downstream flow channel (refer to figure 2 Wait).

[0047] More specifically, as figure 2 As shown, the fluid resistance member 100 includes a main body member 1 , a cover member 2 , and a ring member 3 , which corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com