Test device and test method for static and dynamic characteristics of rolling support linear feed system

A technology of linear feed system and rolling support, which is applied in the testing of machine gears/transmission mechanisms, etc., can solve problems such as difficult measurement of influence laws, and achieve the effects of clear testing principles, wide application, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

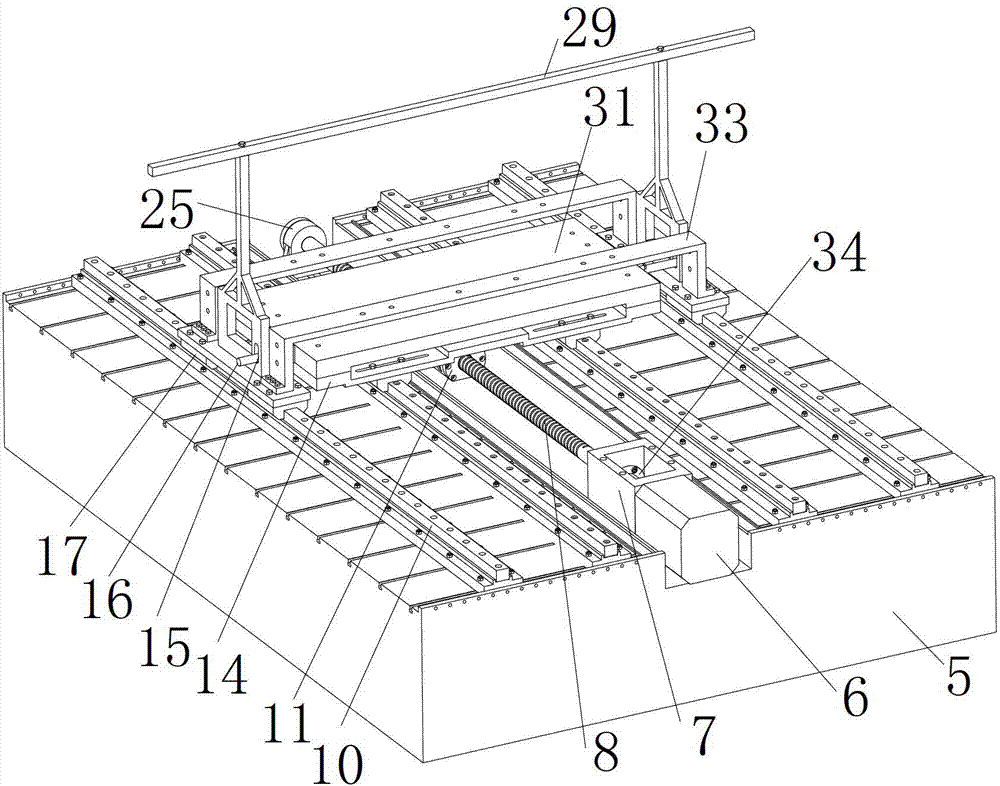

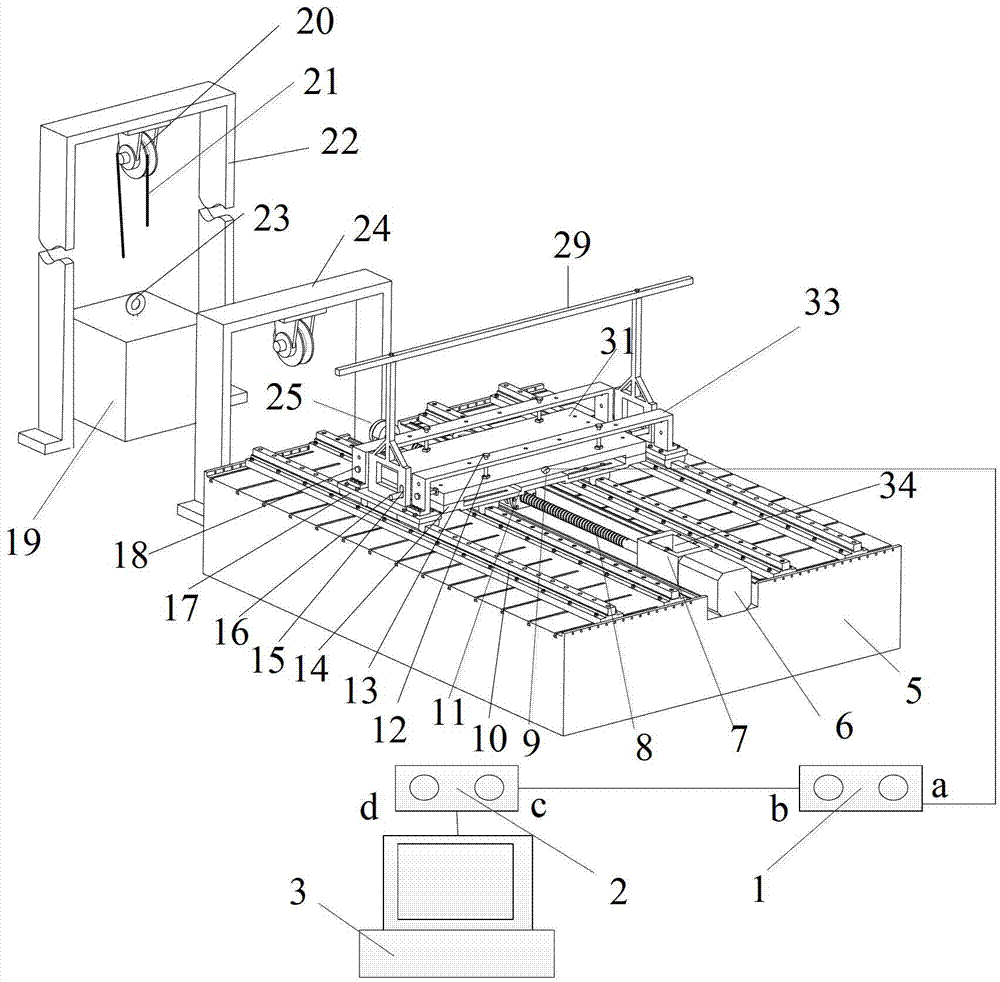

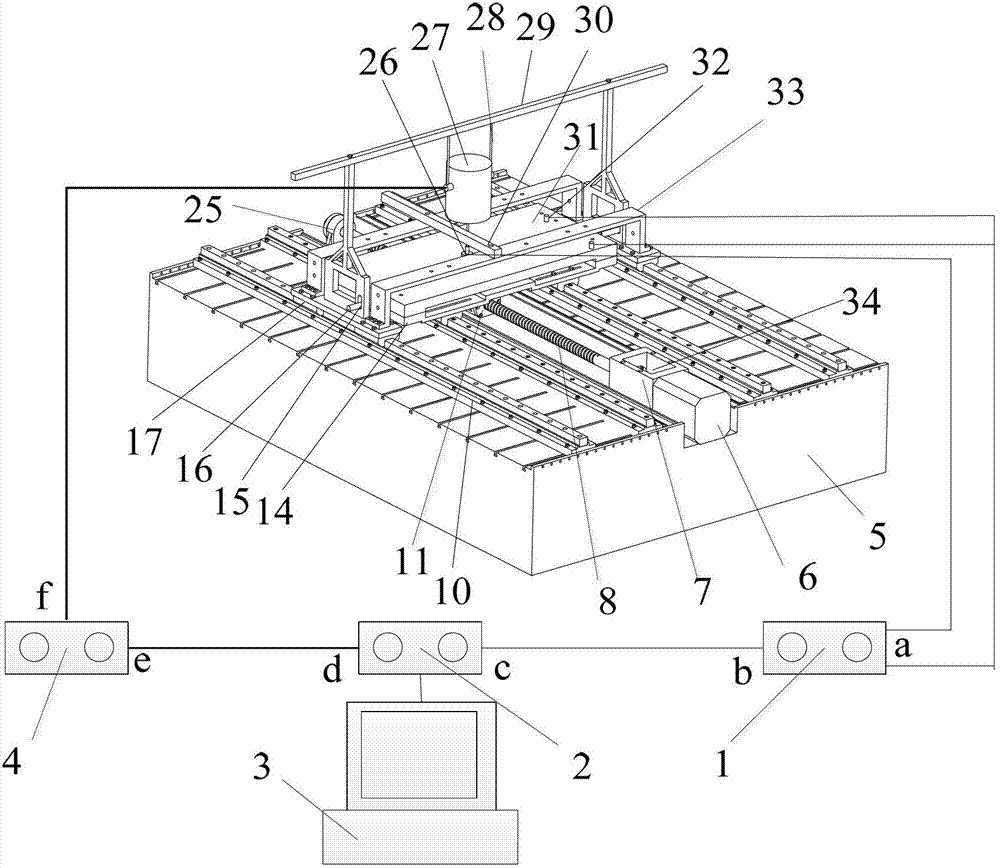

[0040] combine figure 1 , a rolling support linear feed system static and dynamic characteristics testing device, including a test platform and a test system connected to each other, the test platform includes a base 5, a rolling guide rail 10, a rolling guide rail slider 17, a bearing seat 7, a bearing 25 , motor 6, coupling 34, ball screw pair 8, nut seat 11, connecting plate 14, suspension rod 30, workbench 31, synchronization frame 29, synchronization push rod 16, bridge plate 33, rubber ring 15;

[0041] The upper surface of the base 5 is fixedly connected with four mutually parallel rolling guide rails 10, each rolling guide rail 10 is provided with a rolling guide rail slider 17, and a synchronization frame 29 is arranged above the two rolling guide rail sliders in the outer side, and two synchronization frames 29 are arranged on the synchronization frame 29 The bridge plates 33 parallel to each other, the straight line where the bridge plates 33 are located are perpend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com