The method of 3D locator to realize movable measurement

A technology of mobile measurement and locator, applied in the direction of wheel testing, etc., can solve the problems of difficult vehicle locator, lack of measurement accuracy, and inability to use outdoors, and achieve the effect of strong resistance to ambient light interference and high recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

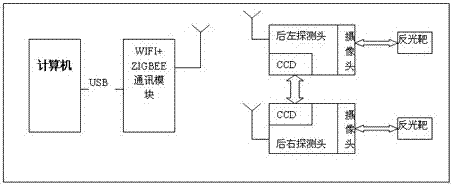

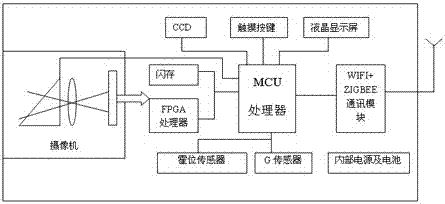

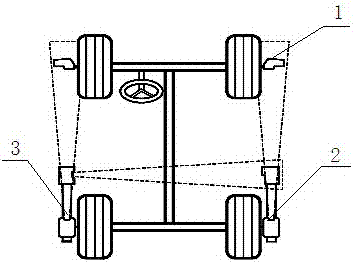

[0016] The coordinate system of the portable 3D locator is established by measuring and calculating the changes in the imaging of the reflective target on the front tire and the reflective target on the car body through the detection head clamped on the rear wheel. The sensor measures the angle between the rotation axis and the concentric axis by identifying the reflective target point on the front tire when the vehicle backs up and rotates at an angle of θ and the change of the reflective target pattern on the car body, and establishes a coordinate system based on the concentric axis. The intersection point of the plane where the outer shaft of the rear left wheel or the rear right wheel is located and the concentric axis is the coordinate zero point, so the measurement site can be changed at will. Since the distance between the identified point and the sensor is relatively fixed, the effective imaging pixels are identified >50% of the total pixels.

[0017] Since the front a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com