Surface mount inductor and method of manufacturing the same

A technology of surface mounting and manufacturing method, applied in the direction of inductor/transformer/magnet manufacturing, transformer/inductor core, transformer/inductor coil/winding/connection, etc., can solve problems such as unfavorable high-density installation, and achieve low height The effect of high-density installation, small electrode area and high-density installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

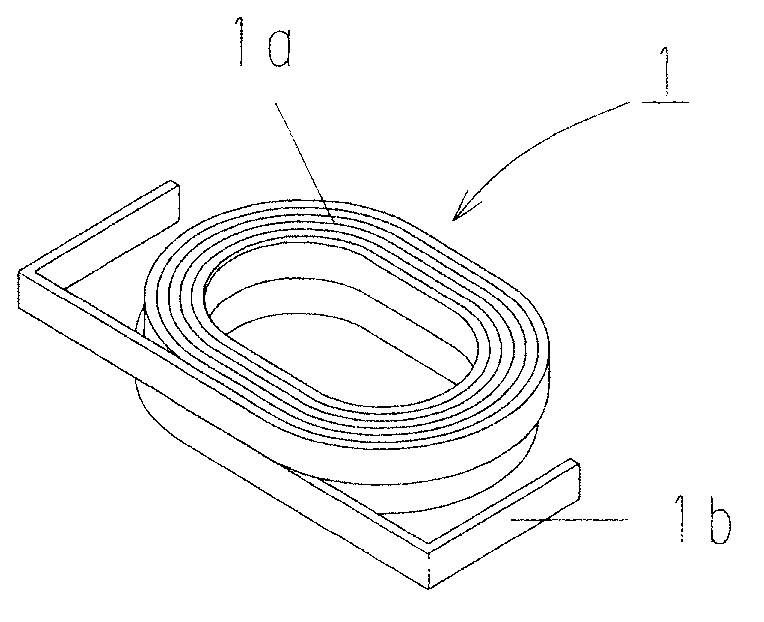

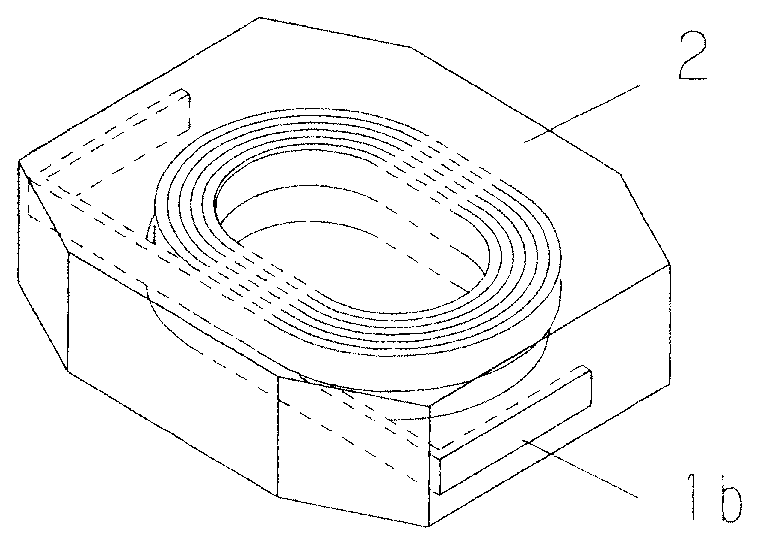

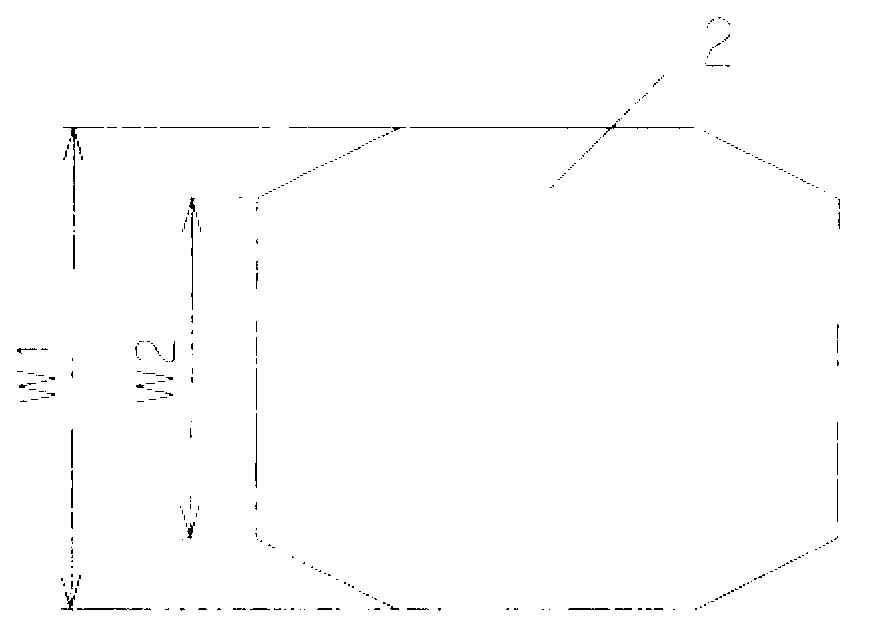

[0026] refer to Figure 1 to Figure 5 , the first embodiment of the surface mount inductor of the present invention will be described. figure 1 A perspective view of a coil used in the following examples is shown. figure 2 with image 3 Represents the core of the first embodiment of the present invention, figure 2 is a stereogram, image 3 For top view. Figure 4 A perspective view showing the surface mount inductor according to the first embodiment of the present invention viewed from the bottom side. Figure 5 A diagram illustrating the external electrodes of the surface mount inductor according to the first embodiment of the present invention is shown.

[0027] First, if figure 1 As shown in , using a winding core with an elliptical cross-sectional shape, a flat wire with a self-adhesive coating is wound into two layers of outer-to-outer winding (wound in such a way that the two wire ends form the outermost circumference). Coil 1. The coil 1 is formed into a sha...

no. 2 Embodiment

[0032] refer to Figure 8 ~ Figure 10 , to describe the second embodiment of the surface mount inductor of the present invention. Figure 8 with Figure 9 Showing the core of the second embodiment of the present invention, Figure 8 is a stereogram, Figure 9 for side view. Figure 10 A perspective view showing a surface mount inductor according to a second embodiment of the present invention viewed from the upper surface side. In addition, the sealing material used in the first embodiment is used in the second embodiment. The description of the part overlapping with the first embodiment is omitted.

[0033] First, the core 12 is formed by compression molding in such a manner that the coil is sealed inside the core 12 with a sealing material. exposed. In this embodiment, as in the first embodiment, the core portion 12 is formed in an octagonal shape, and, as Figure 9 As shown, the upper surface of the core 12 is tapered such that the height H2 of the end surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com