High-power battery charging device capable of preventing reverse current charging and battery reversal

A current backfeeding and battery charging technology, which is applied to battery circuit devices, circuit devices, emergency protection circuit devices, etc., can solve the problems of personnel electric shock, external exposure, polarity reverse connection, etc., to prevent personnel from electric shock and battery short circuit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

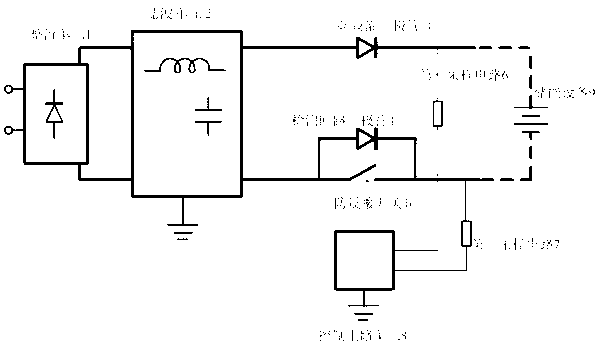

[0012] Such as figure 1 As shown, the high-power battery charging device that prevents current backfeeding and battery reverse connection includes a rectifier unit 1 and a filter unit 2. The output terminal of the rectifier unit 1 is connected to the filter unit 2, and the positive output terminal of the filter unit 2 is connected to the anti-backfeed unit. Diode 3, the output negative terminal of the filter unit 2 is connected to the anti-reverse connection switch 5 and the detection circuit diode 4, the control circuit unit 8 is connected to the anti-reverse connection switch 5 to control the opening and closing of the anti-reverse connection switch 5, and the anti-reverse connection diode 3 The cathode of the detection loop diode 4 is connected to the first sampling circuit 6, the cathode of the detection circuit diode 4 and one end of the anti-reverse connection switch 5 are connected to the second sampling circuit 7, the first sampling circuit 6 and the second sampling cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com