Controllable silicon closing time prolonging control technology for motorcycle fuel saving rectifier

A technology of closing time and control technology, applied in the direction of output power conversion device, electrical components, etc., can solve the problems of fuel waste, high temperature of thyristor, large load of magneto, etc., and solve the problem of breakdown and high temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

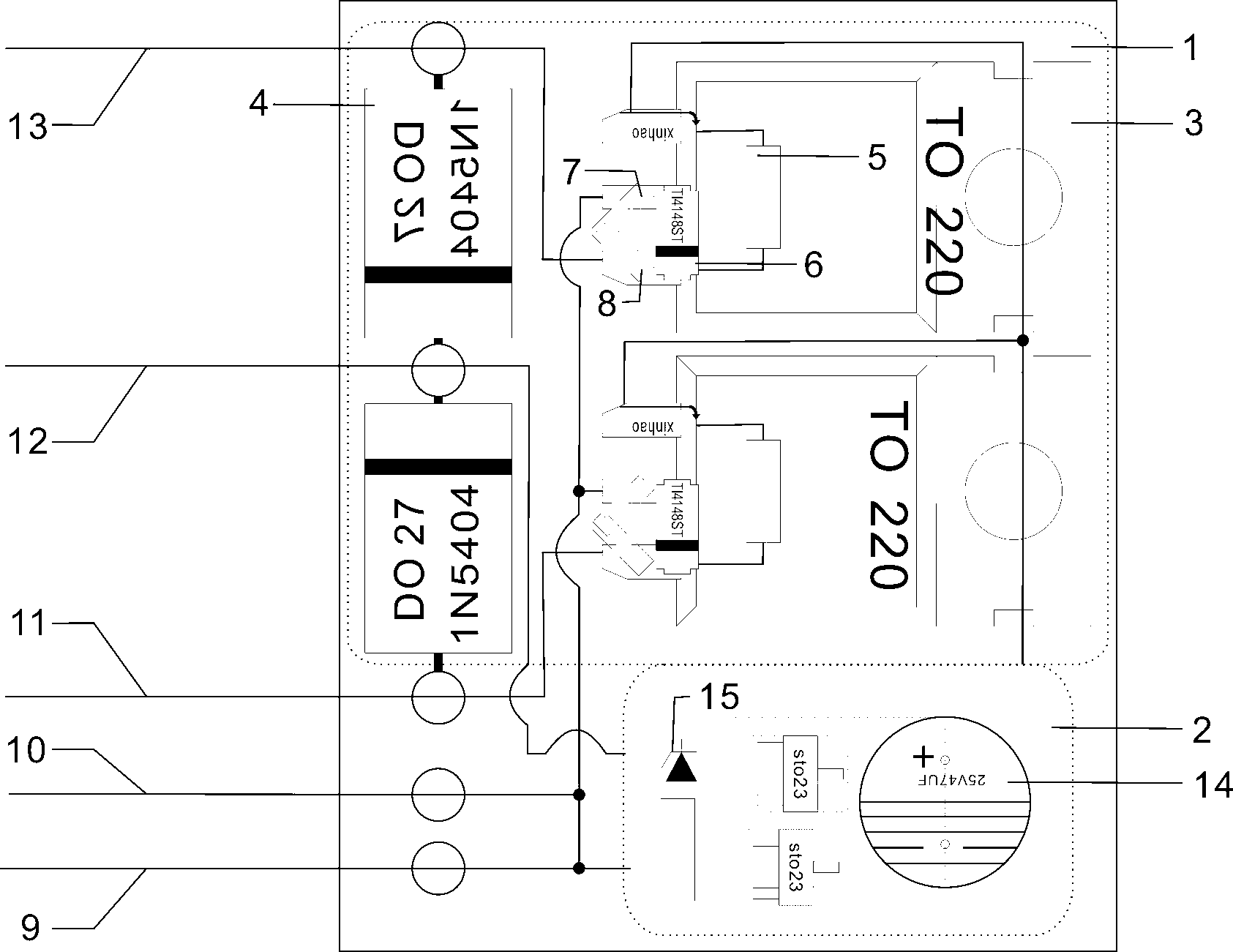

[0021] figure 1 It is a structure diagram of a rectifier shut-off time extension control technology of a motorcycle fuel-saving rectifier in the present invention. The present invention is composed of a controllable rectification part 1 and a voltage stabilizing part 2. exist figure 1 Among them, the controllable rectification part 1 is mainly composed of a silicon controlled rectifier 3 and a rectifier diode 4. The cathodes of two rectifier diodes 4 are connected to each other and a positive line 12 is drawn out. Connect and lead out the No. 1 AC line 11 and the No. 2 AC line 13 respectively. The anodes of the two thyristors 3 are connected in parallel and lead out a negative line 9 and a negative line 10 of the battery. The positive line 12 and the negative line 9 are synchronized The input is connected to the input terminal of the voltage stabilizing part 2, the output terminal of the voltage stabilizing part 2 is connected in parallel with the control poles of the two thy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com