Control circuit and control method of primary side feedback constant current

A control circuit, primary side technology, applied in the direction of electric lamp circuit layout, control/regulation system, electric light source, etc., to achieve the effect of improving the constant current effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

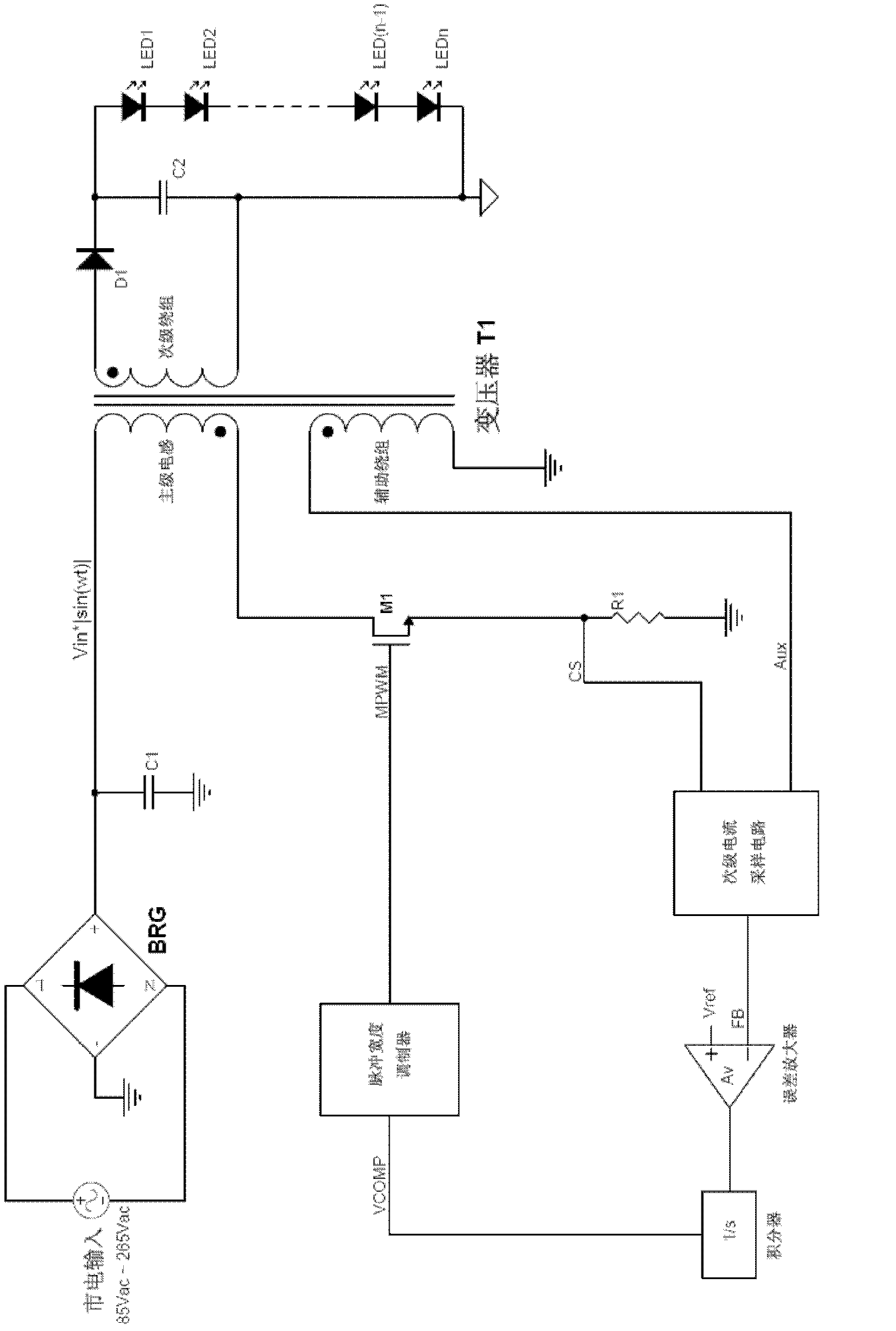

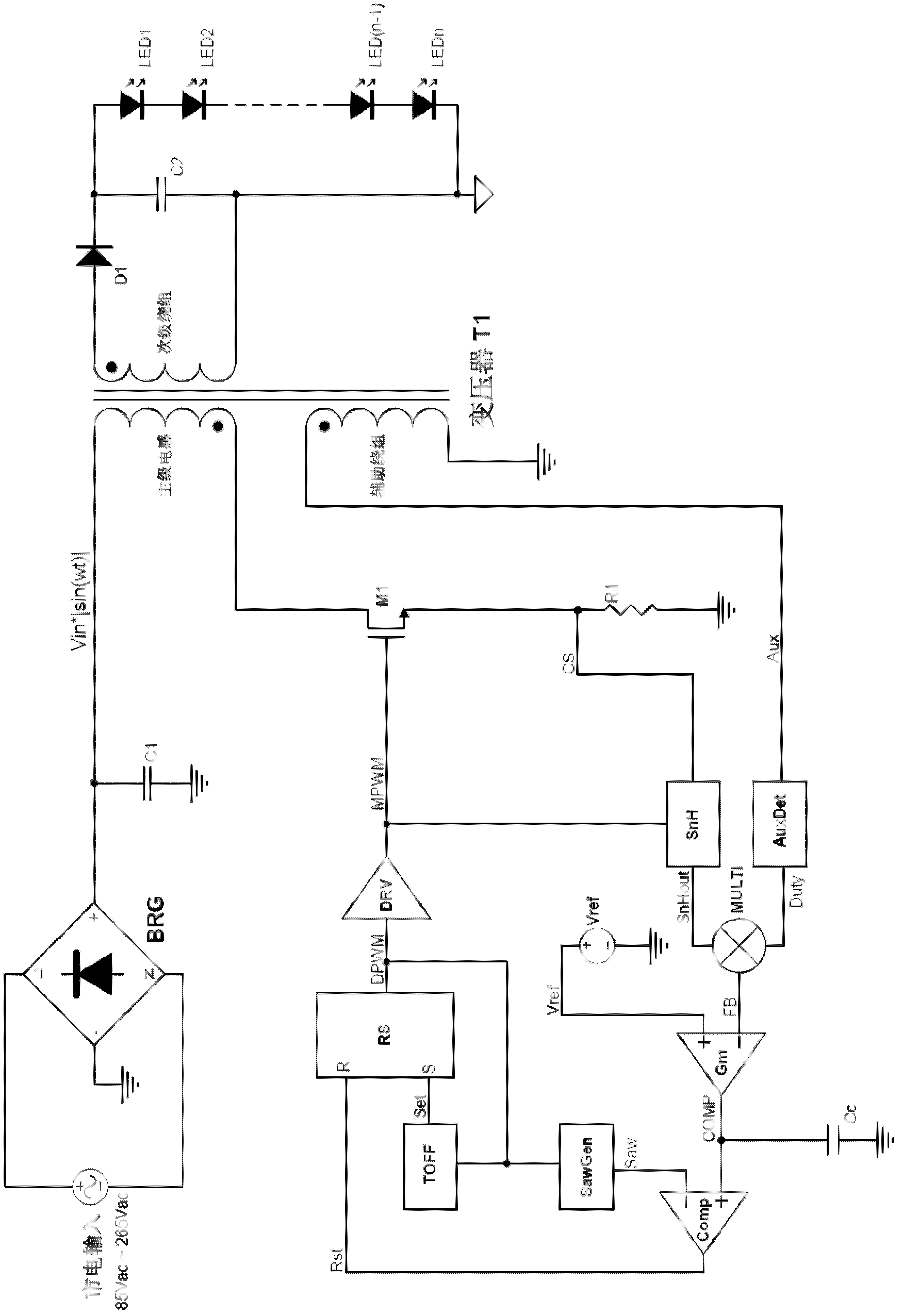

[0019] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the present invention.

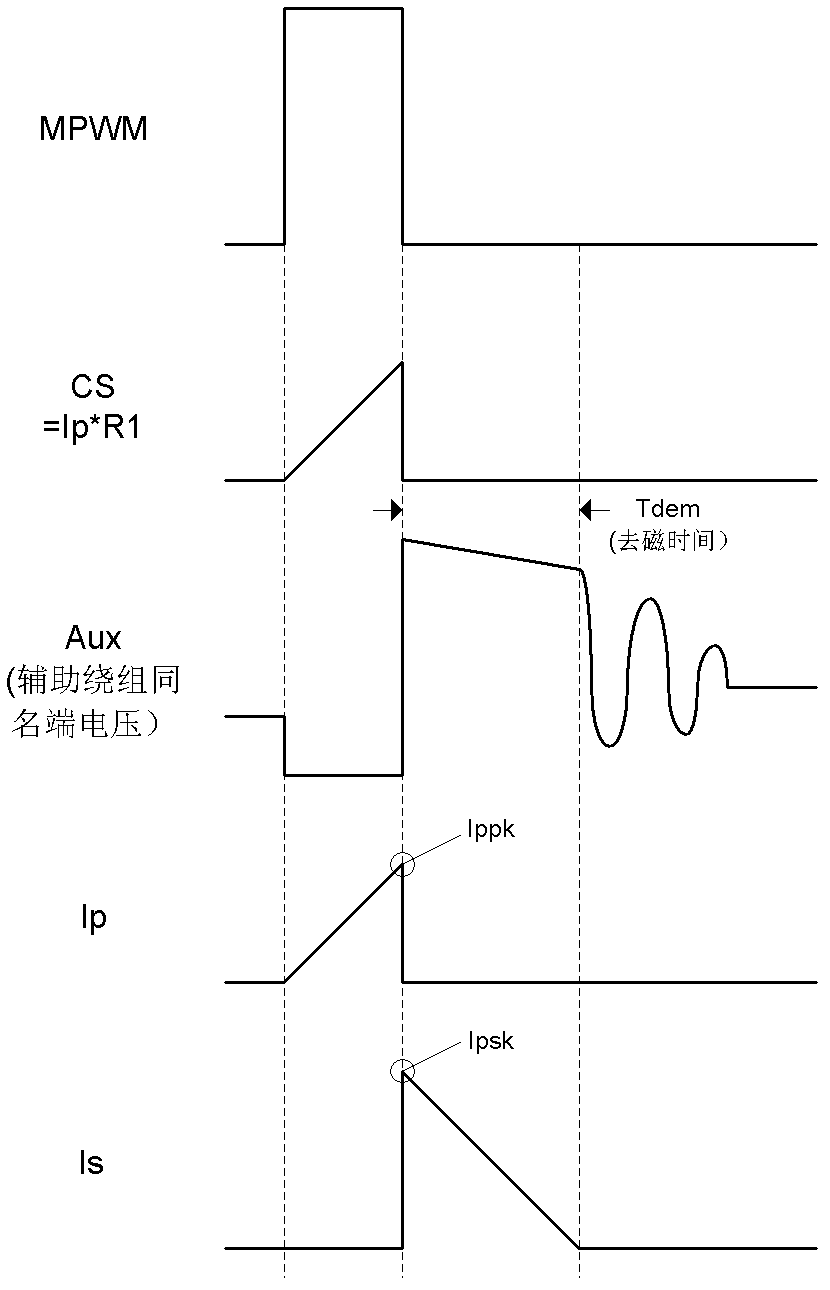

[0020] figure 2 based on figure 1 Waveform diagram of each node under the control of the structure. figure 2 Among them, CS is the voltage waveform at both ends of the sampling resistor R1; Aux is the voltage waveform at the terminal with the same name of the auxiliary winding. According to the working principle of the transformer, the secondary winding voltage is proportional to the auxiliary winding voltage; Ip is the primary inductor current waveform, and Ippk is at In each switching cycle, the peak value of the primary inductor current; Is is the waveform of the secondary inductor current, and Ispk is the peak value of the secondary inductor current in each switching cycle.

[0021] Assuming that the switching period of MPWM is T, then in any switching period nT, the output current of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com