Chewing gum base containing polyfarnesene and chewing gum products made there from

一种口香糖胶基、聚法尼烯的技术,应用在口香糖领域,能够解决难以始终如一地配制高品质的口香糖产品等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] The following examples of the invention and comparative formulations are provided to illustrate and not to limit the invention defined by the claims. Amounts listed are in weight percent.

[0065] Four polyfarnesenes with different molecular weights were prepared. The reaction mechanism of preparation is as follows:

[0066]

[0067] Molecular weight, polydispersity (determined by GPC), glass transition temperature (determined by DSC), and thermal degradation (temperature at which 1% of the sample is lost during thermogravimetric analysis) were measured for two polyfarnesene samples, and They are reported in Table 1 below.

[0068] Table 1

[0069]

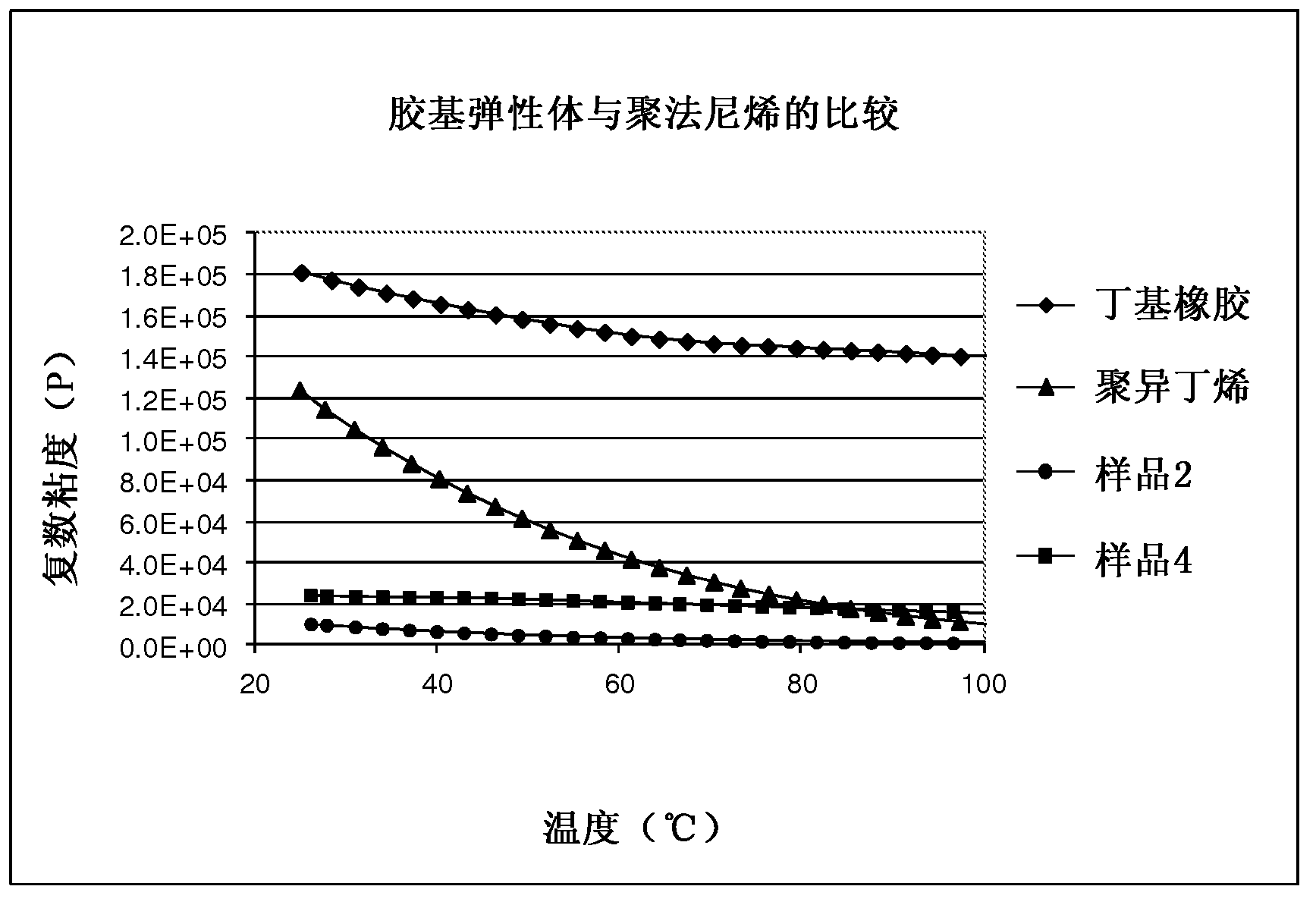

[0070] figure 1 The complex viscosities of polyfarnesene samples 2 and 4 are shown compared to two conventional chewing gum base elastomers, butyl rubber and polyisobutylene. Complex viscosity (reported in poise (P)) is a good property for comparing polymers being considered for use in gum base. Complex viscosit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com