Apparatus for manufacturing glass sheet and method for manufacturing glass sheet

A manufacturing device and manufacturing method technology, which is applied in the field of glass plate manufacturing devices, can solve the problems of glass ribbon deformation, gas temperature influence, product warping, etc., and achieve the effect of suppressing warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

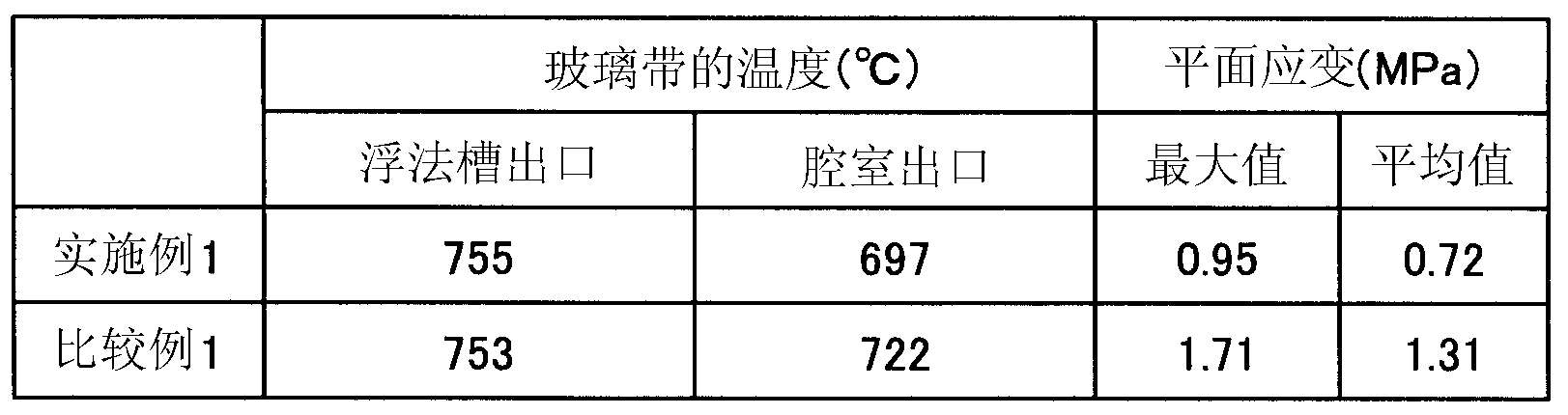

[0125] Hereinafter, the present invention will be specifically described using examples and the like, but the present invention is not limited by these examples.

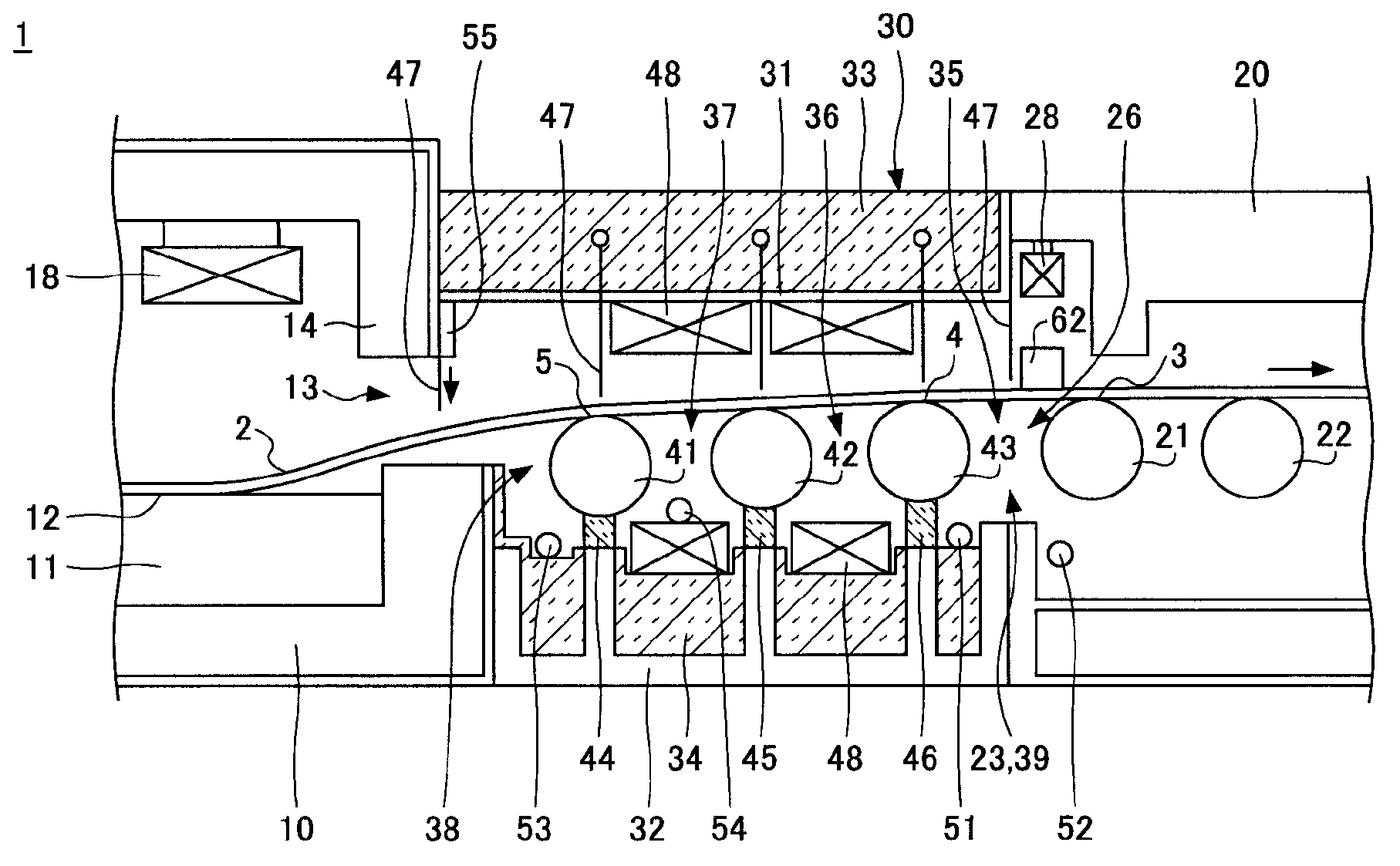

[0126] In Example 1, using figure 1 The shown manufacturing apparatus 1 manufactures the glass plate of 1800 mm in length x 1500 mm in width x 0.7 mm in thickness. Glass with an annealing point of 711° C. was used for the glass of this glass plate.

[0127] Apart from figure 1 In addition to the second air supply pipe 52 shown, since figure 1 Nitrogen is used as the gas supplied from the first gas supply pipe 51 , the third gas supply pipe 53 , the fourth gas supply pipe 54 , and the fifth gas supply pipe 55 shown. Air is used as the gas supplied from the second gas supply pipe 52 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap