Energy-saving diaphragm type pressure filter

A diaphragm type, energy-saving technology, applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of affecting the water content of the filter cake, increase, and the efficiency of machine filtration can not be obtained, and reduce the water content. , the effect of saving steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

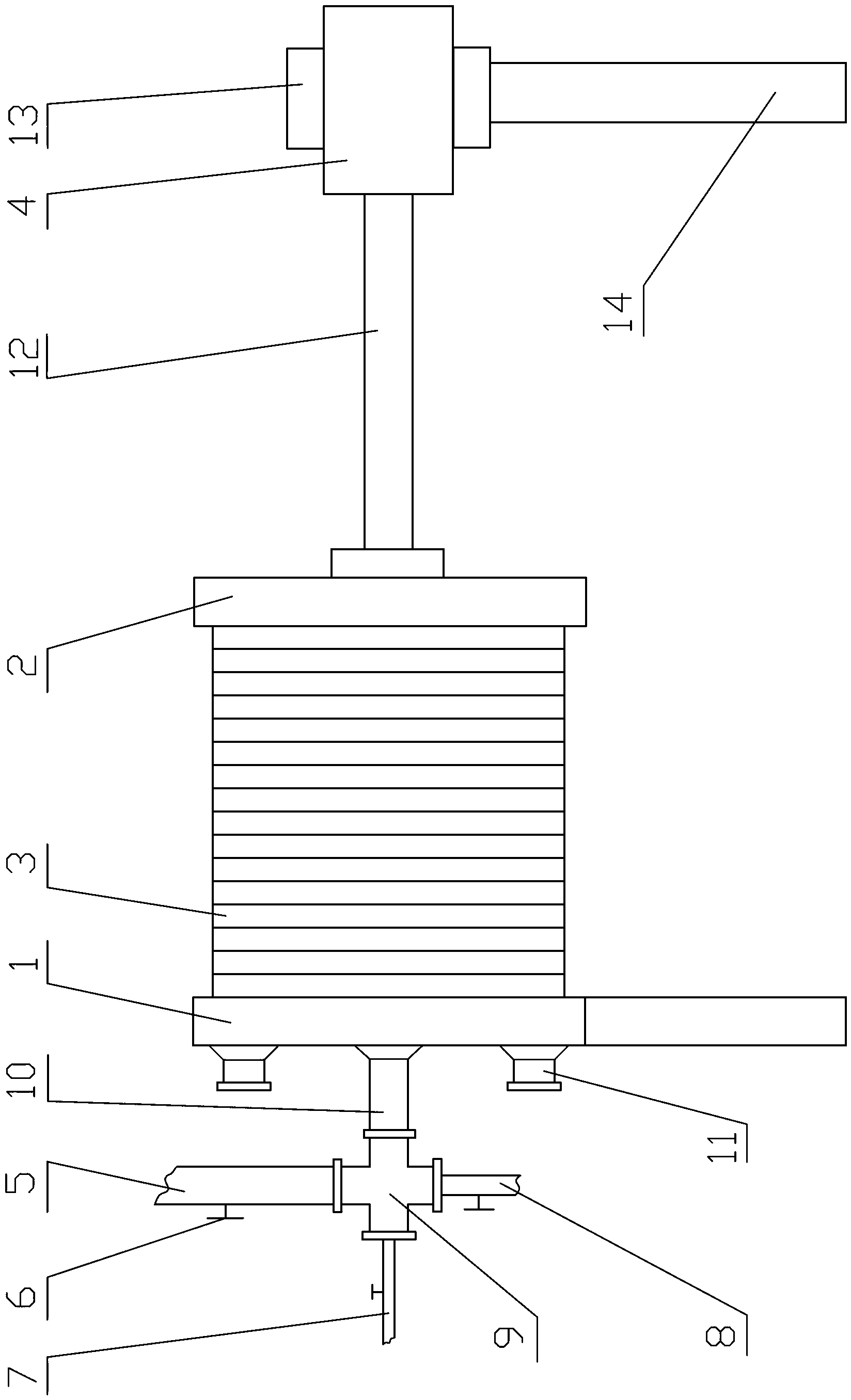

[0014] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

[0015] The energy-saving diaphragm filter press of the present invention comprises parts such as thrust plate 1, pressing plate 2, filter plate 3, top pressure oil cylinder 4, oil cylinder seat 13 and beam, and two beams connect oil cylinder seat 13 and thrust plate 1 Connected into a rectangular horizontal frame and supported on the bracket 14, the top pressure cylinder 4 is installed in the oil cylinder seat 13, the horizontal piston rod 12 of the top pressure cylinder 4 is stretched forward and connected to the compression plate 2 (placed on the beam), and the pressure is pressed The plate 2 is arranged opposite to the thrust plate 1, and several filter plates 3 are arranged in sequence and pressed between the pressing plate 2 and the thrust plate 1, and filter cloth is sandwiched between the filter plate 3 and the filter plate 3. A layer of elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com