Feeding robot of drilling and tapping machine tool

A technology of robots and machine tools, applied in the field of transmission shafts, can solve the problems of high labor intensity, low production efficiency, and short service life of workers, and achieve the effects of improving production efficiency and economic benefits, saving processing time, and reasonable and practical design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

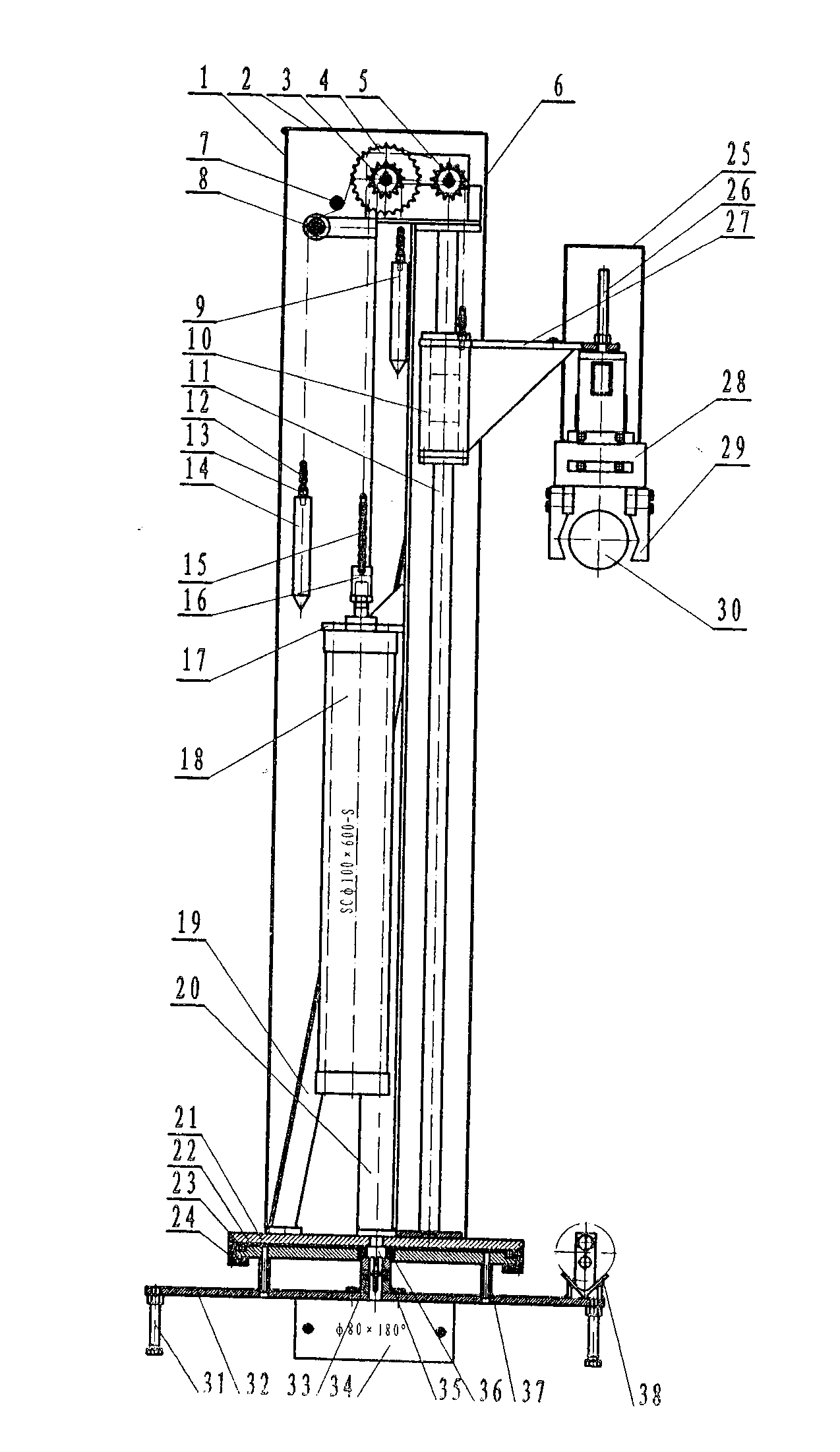

[0006] As shown in the figure, the feeding robot for drilling and tapping machine tools is mainly composed of a cover body 1, a cover cover 2, a small driving sprocket 3, a large driving sprocket 4, a supporting sprocket 5, a dust shield 6, and a chain pressing wheel 7. Support wheel 8, first weight 9, sliding sleeve 10, polished rod 11, lifting chain 12, chain joint 13, second weight 14, driving chain 15, cylinder joint 16, cylinder fixing plate 17, lifting cylinder 18. Column tie bars 19, column angle iron 20, turntable 21, load-bearing plate 22, turntable steel ball 23, turntable pressure plate 24, manipulator cover 25, lifting screw 26, lifting arm 27, manipulator cylinder 28, manipulator claw 29, workpiece 30 , supporting foot 31, bottom plate 32, coupling 33, gyrator cylinder 34, turntable shaft 35, turntable bearing 36, bottom plate spacing sleeve 37 and discharge V-shaped iron 38; 2 and dust baffle 6, the position on the inside is provided with driving small sprocket 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com