Solar energy internal light source microalga bioreactor

A technology of microalgae biology and solar energy, which is applied in the field of solar thermal utilization and bioengineering, and can solve the problems of high cost and small space, such as automatic or manual

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical scheme of the solar internal light source microalgae bioreactor of the present invention will be further described below in conjunction with the accompanying drawings and examples.

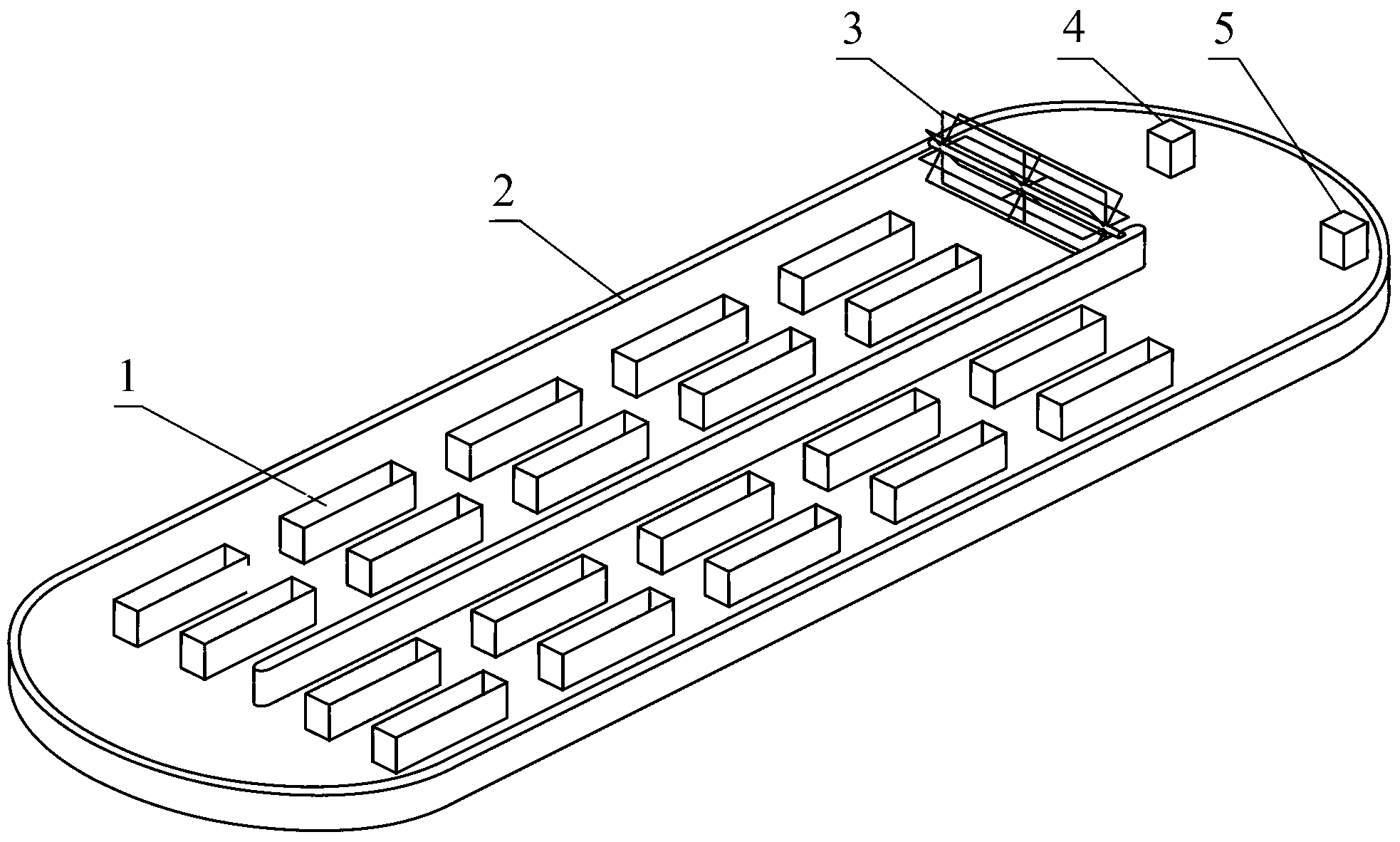

[0027] Such as figure 1 As shown, the solar internal light source microalgae bioreactor of the present invention includes a runway pool 2, a stirring impeller 3, an air supply device 4 and a liquid supply device 5, and a solar internal light source module 1 is arranged in the runway pool 2. Among them, the solar inner light source module 1, the key component, is a light-transmitting container with an upward opening, an impermeable surrounding and a bottom, made of a transparent plate with a smooth surface, and the specific shape of the module can be in many ways.

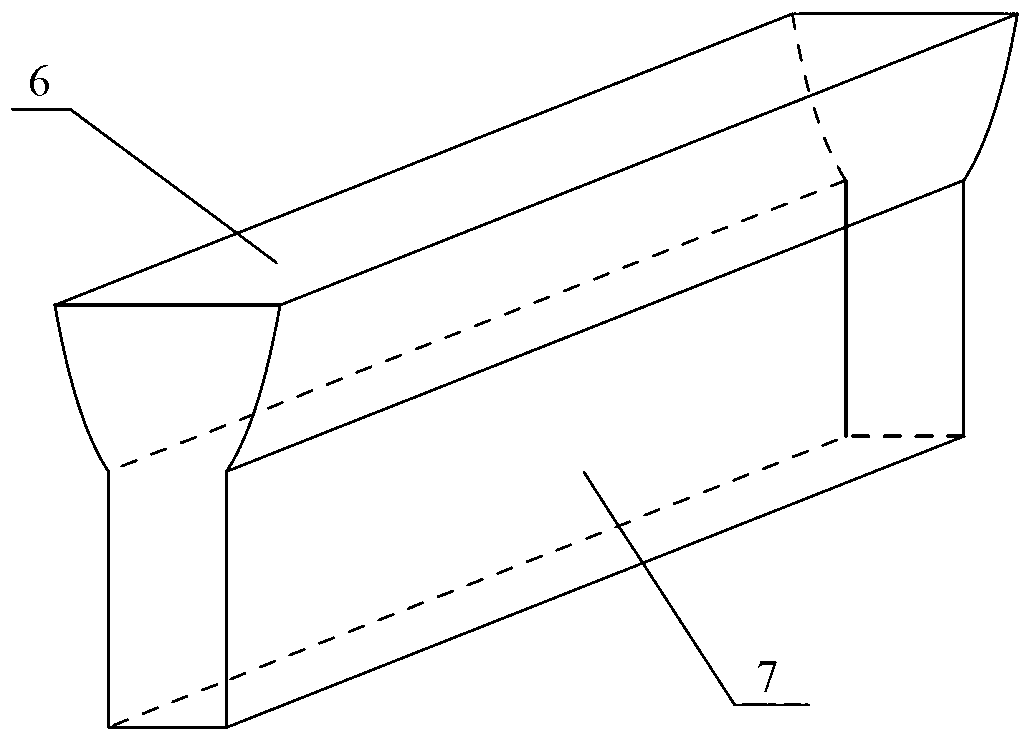

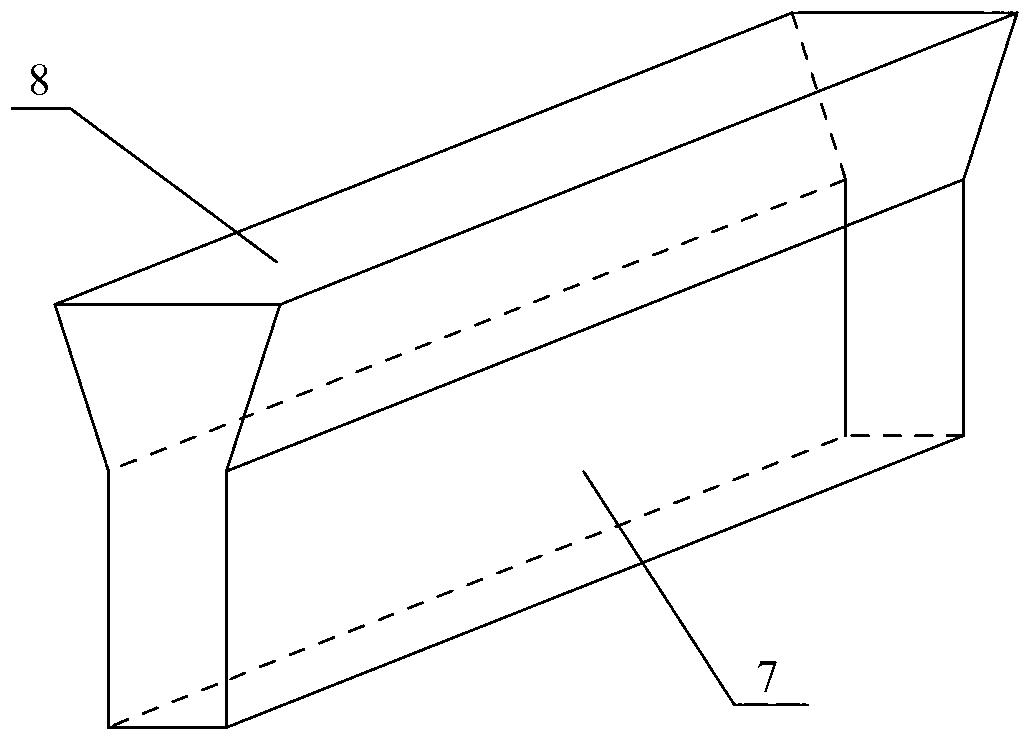

[0028] figure 2 Shown is a way of the solar energy internal light source module 1, which is composed of a rectangular light guide groove and a deformed CPC groove 6; the cross section of the deformed CPC groove 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com