Temperature-raising/temperature-measuring humidifying control method for ginning processing

A control method and temperature control technology, applied in the direction of textiles and papermaking, mechanical treatment, fiber treatment, etc., can solve the problems of lint comprehensive grade decline, affect production and processing, temperature and humidity can not meet the requirements, etc., to reduce production costs, Ease of operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

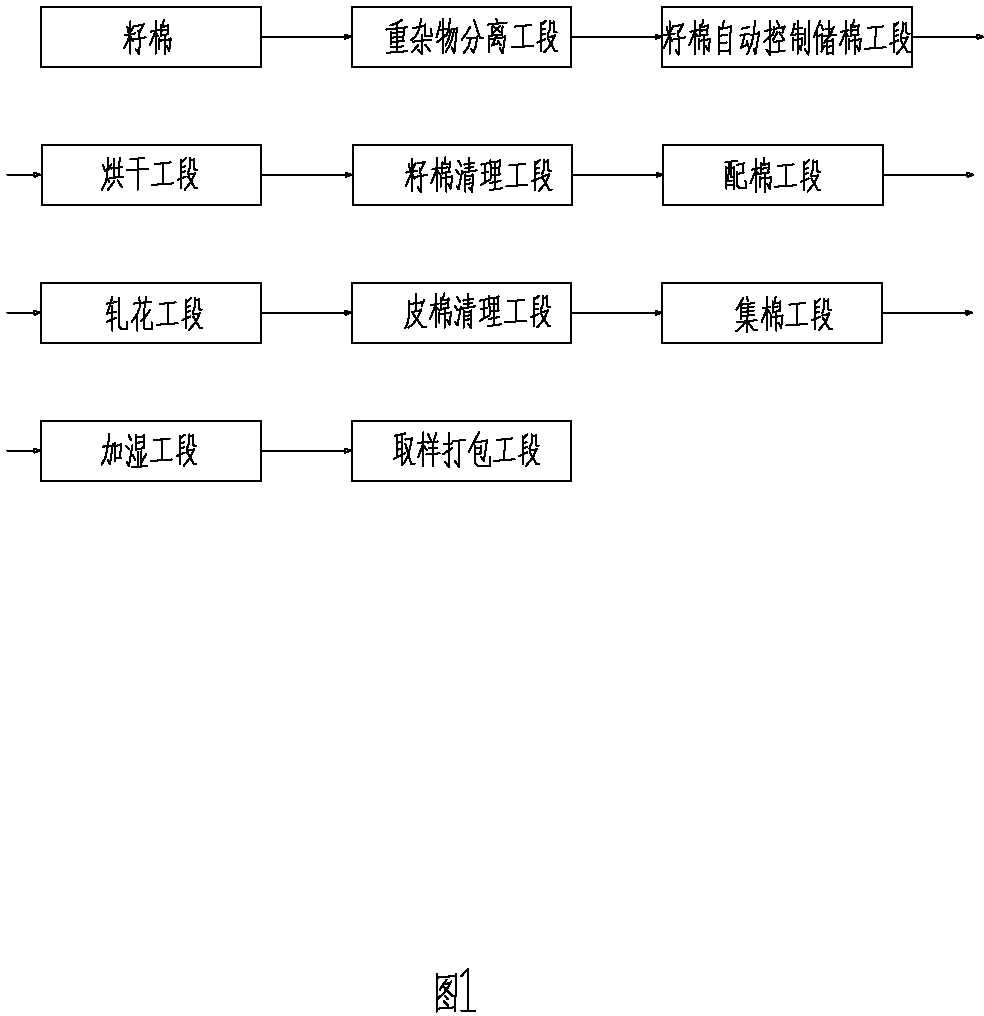

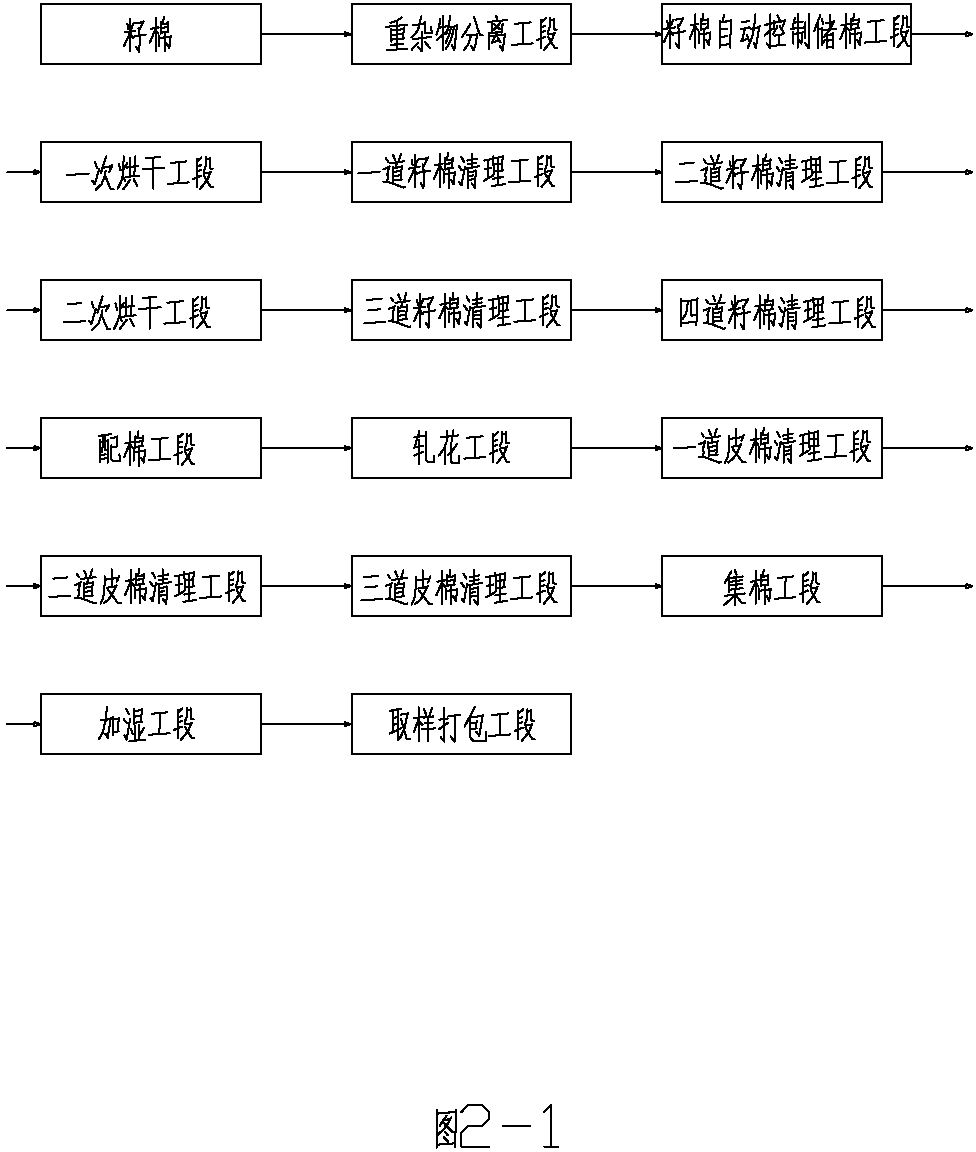

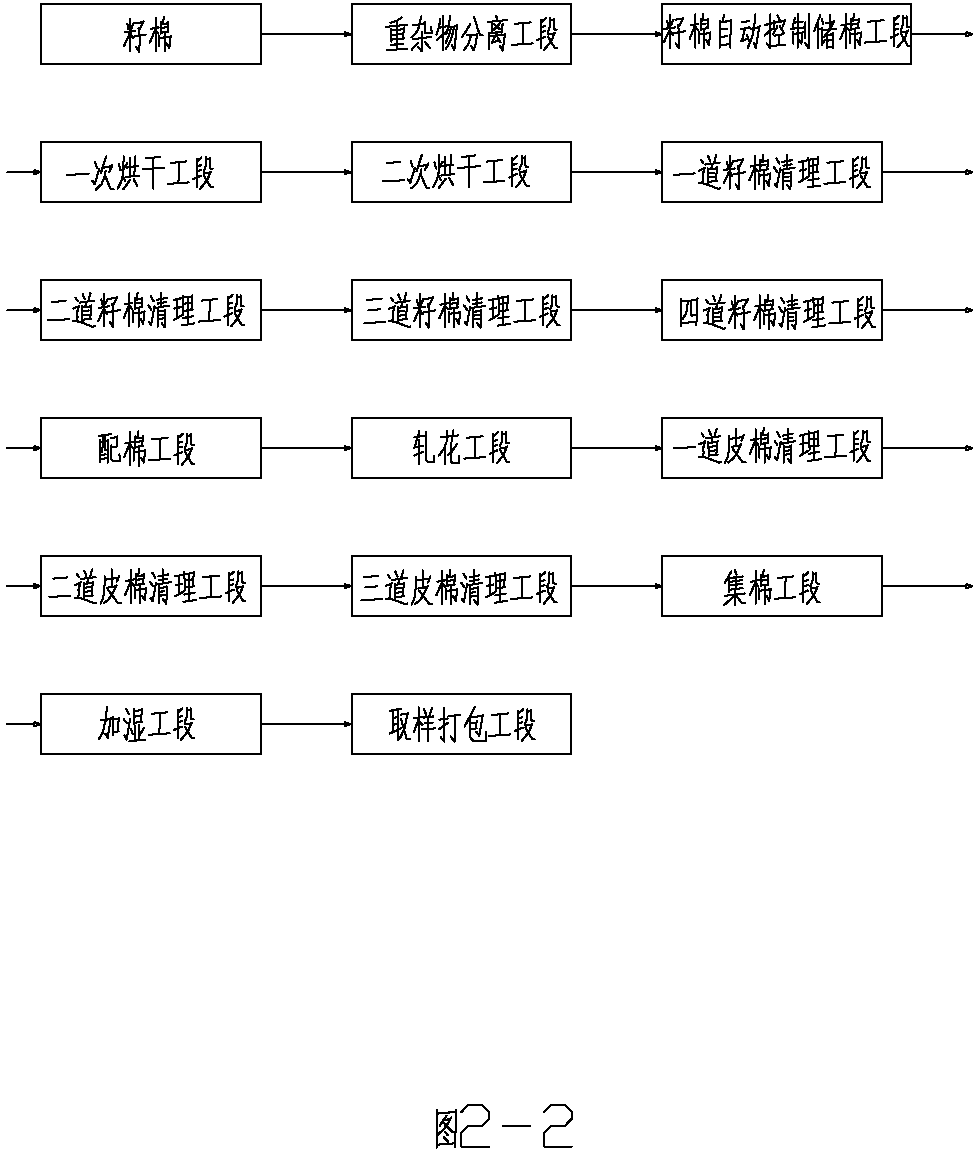

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, as attached Figure 4 As shown, the control method of increasing / measuring temperature and humidifying in the ginning process includes heavy debris separation section, seed cotton automatic control cotton storage section, drying section, seed cotton cleaning section, cotton blending section, ginning section, lint cleaning section and Sampling and packaging section; set up / temperature measurement and humidification processing section between the drying section and seed cotton cleaning section, and the seed cotton coming out of the drying section is subjected to increasing / temperature measurement and humidification treatment in the increasing / temperature measurement and humidification treatment section, so that the seed cotton The temperature is controlled at 15°C to 40°C, and the humidity of the seed cotton is controlled at 5% to 10%.

Embodiment 2

[0035] Embodiment 2, as attached Figure 4 As shown, in embodiment 2, a seed cotton heating pretreatment section is set between the heavy debris separation section and the seed cotton automatic control storage section, and the seed cotton coming out of the heavy debris separation section is heated and pretreated in the seed cotton heating pretreatment section, so that the seed cotton The temperature is controlled at 15°C to 40°C.

Embodiment 3

[0036] Example 3, the seed cotton heating pretreatment method in Example 3 is electric heating or blowing hot air heating; when the temperature of the seed cotton in the cotton pipeline is lower than 15°C, the seed cotton is heated and pretreated, that is, the seed cotton is heated in the pretreatment section. The seed cotton is heated by electric heating or hot air blowing, so that the temperature of the seed cotton is controlled at 15°C to 40°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com