Automatic down feather filling machine

An automatic and down technology, applied in textiles and papermaking, fiber processing, flocking processing, etc., can solve the problems of affecting the working environment, high price, down spillage, etc., to improve the working environment, reduce labor intensity, and avoid down spillage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described below in conjunction with accompanying drawing.

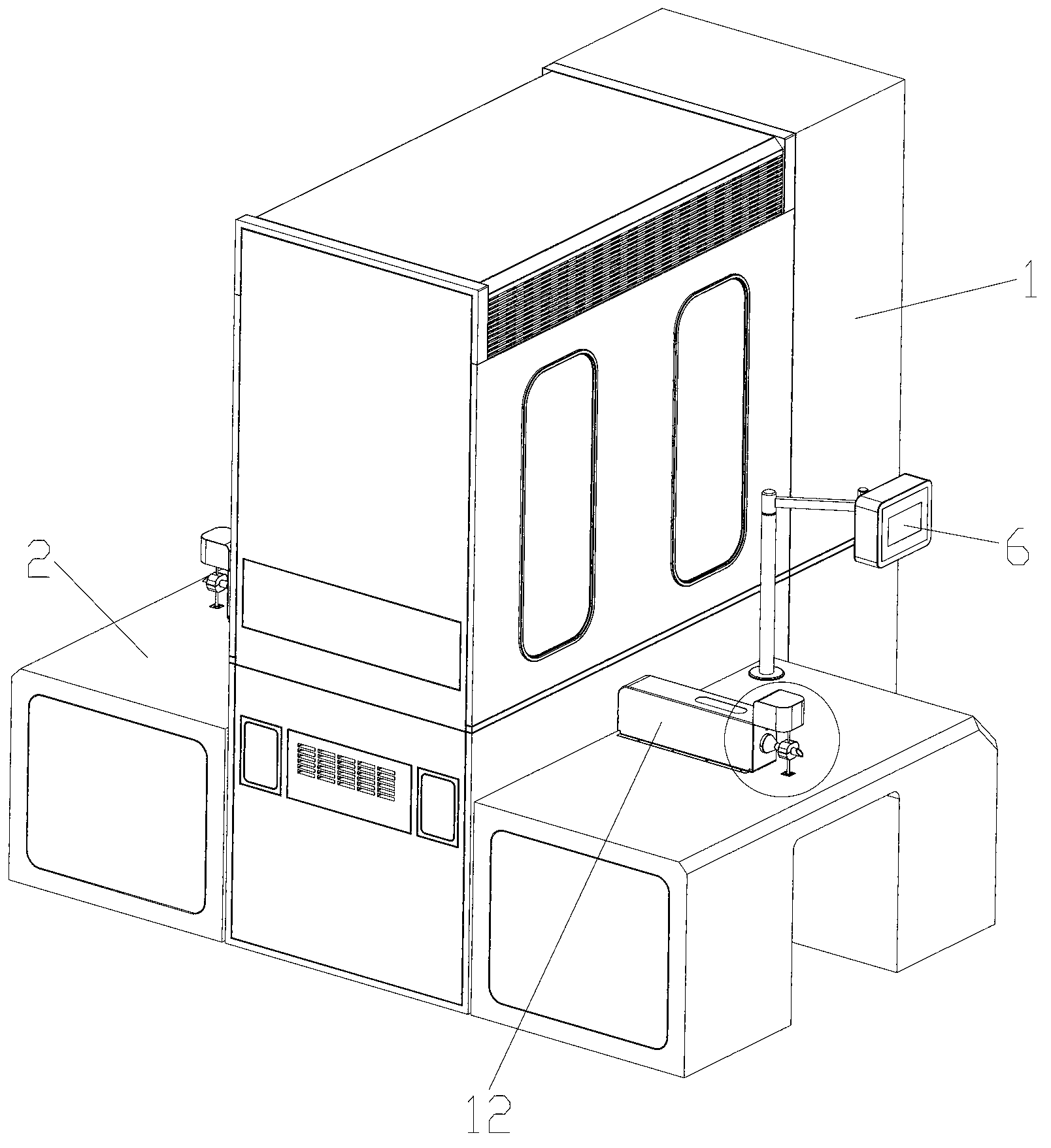

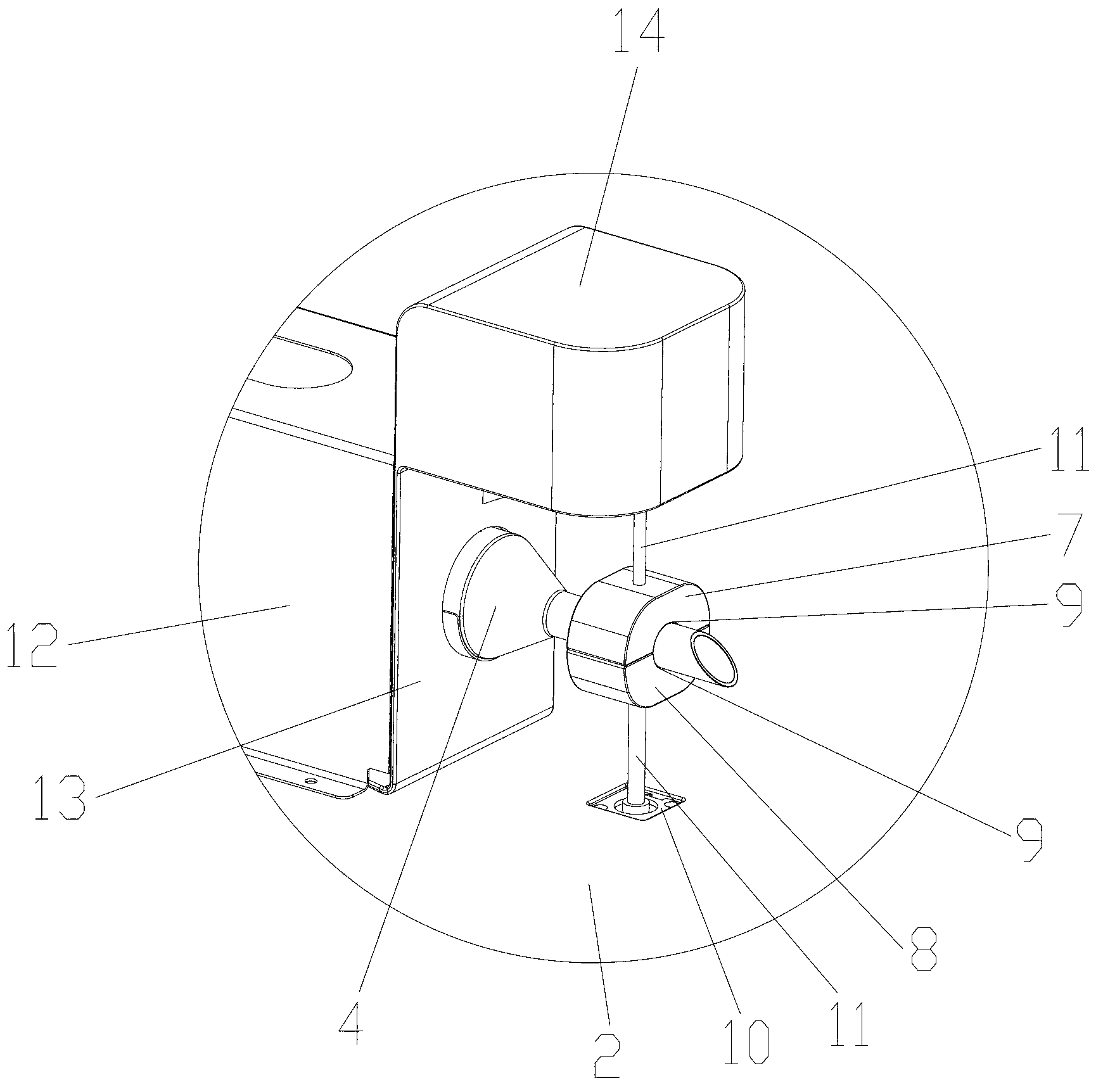

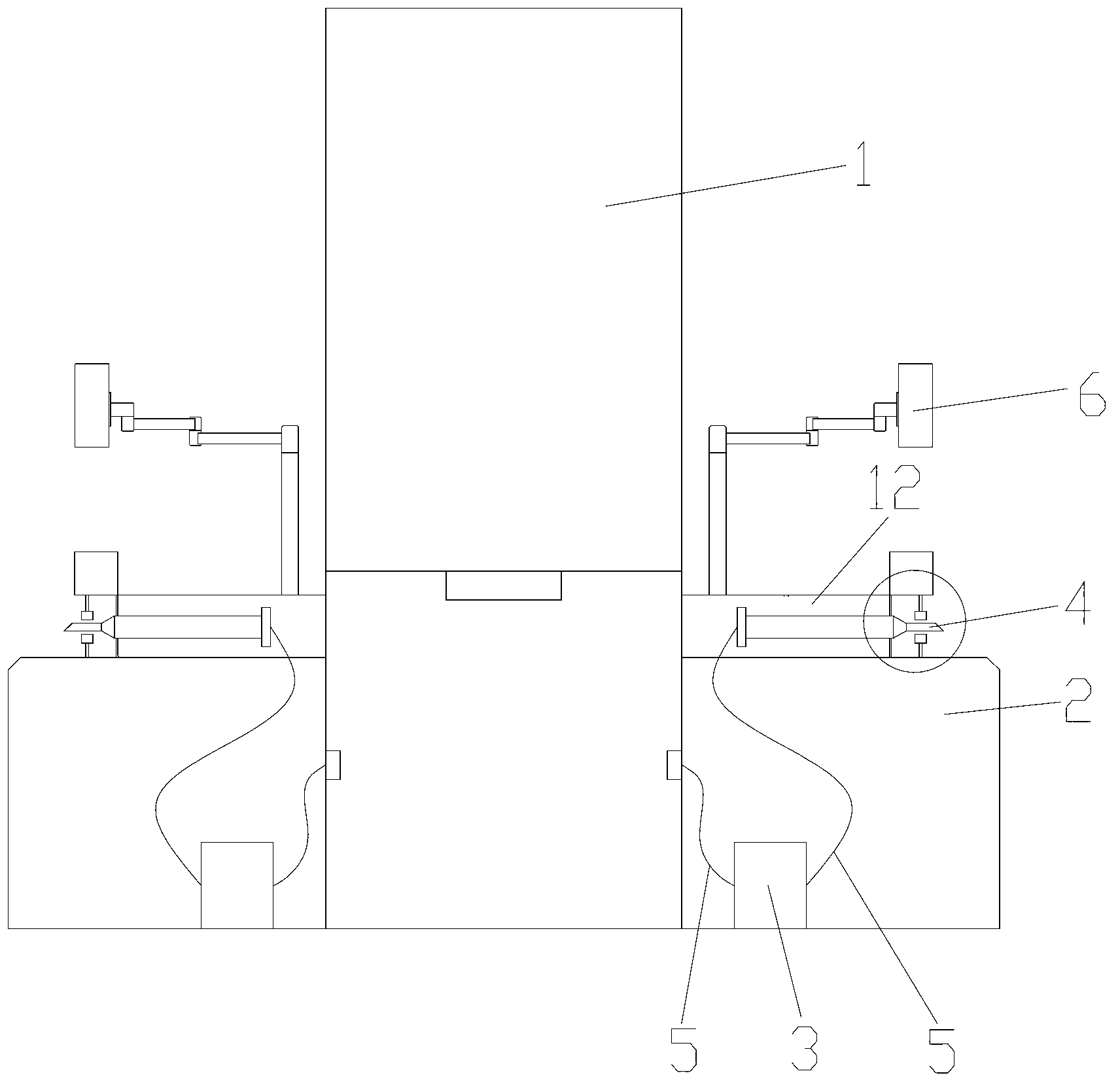

[0022] as attached figure 1 , 2 The shown automatic down filling machine of the present invention includes a down storage box 1, a weighing cabinet 2, a weighing box 3, a down filling tube 4, a control mechanism and a transmission mechanism 5; the weighing cabinet 2 is arranged in Both sides of the cashmere storage box 1; the weighing box 3 is arranged in the weighing cabinet 2; the filling tube 4 is arranged on the weighing cabinet 2, and is connected with the transmission mechanism 5; the transmission mechanism 5 is controlled by the mechanism control; the control mechanism controls the transmission mechanism 5 to transport the down in the down storage box 1 to the weighing box 3, and then discharges the down in the weighing box 3 from the down filling tube 4; the front end of the down filling tube 4 is provided with a lock Clamping device; the locking and clamping device is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com