Vacuum filling and sealing device for warhead

A warhead and potting technology, which is applied in the field of equipment for potting and sealing weapon warheads, can solve the problems of the potting glue cannot continue to be potted, the potting glue is difficult to be filled in place, and the amount of the warhead is reduced. The effect of charging process cost, reducing charging cost and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

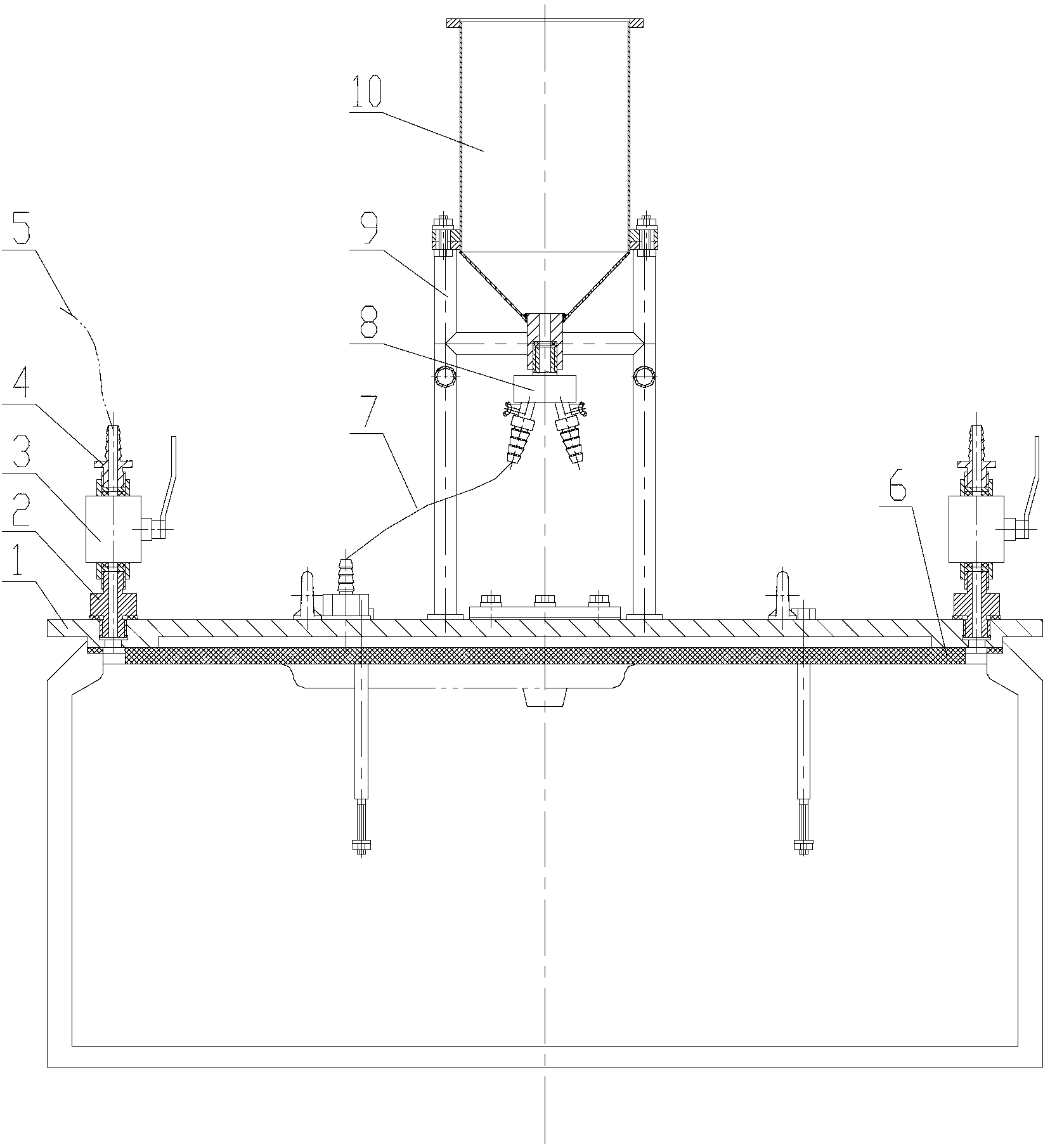

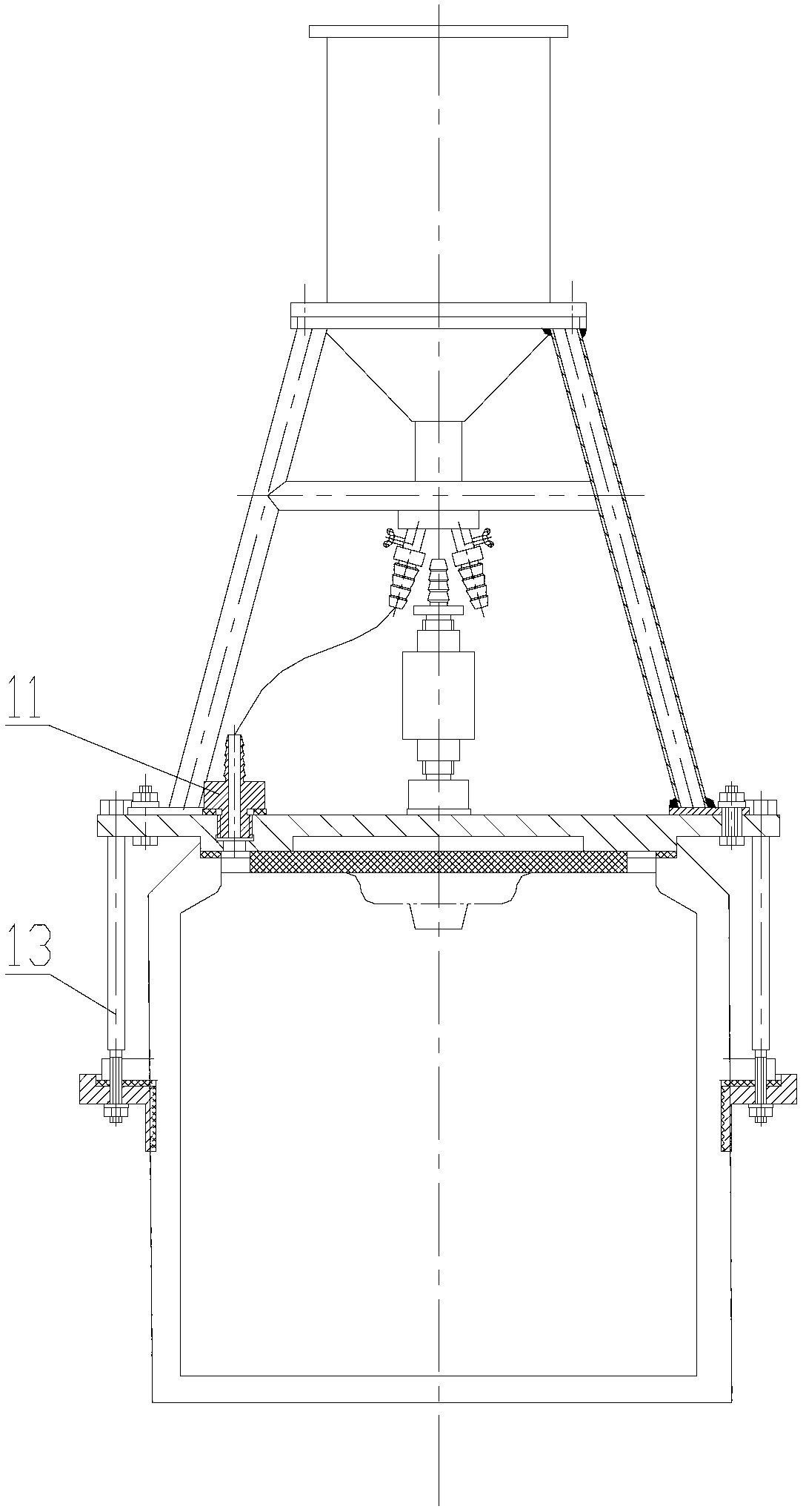

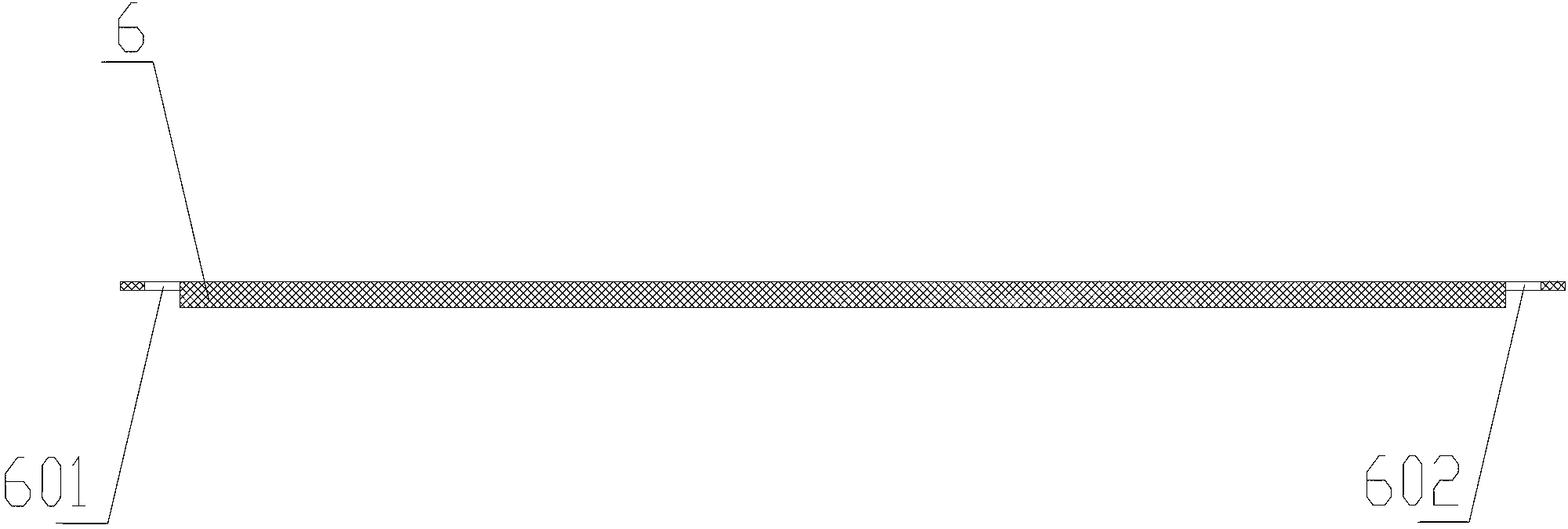

[0026] figure 1 is the front view of the warhead vacuum potting device, figure 2 yes figure 1 Side view of the warhead vacuum potting setup shown. combine figure 1 and figure 2 The combat head vacuum potting device of the present invention will be described in detail. The vacuum potting device for the warhead includes a potting device body and vacuum equipment arranged on the potting device body. The potting device body includes a cover plate 1 used in conjunction with the mouth of the warhead shell, a hopper 10 for holding the potting glue, and a fixed hopper 10 is also arranged between the hopper 10 and the cover plate 1 And the hopper support 9 of the cover plate 1, the end of the hopper close to the cover plate is provided with a discharge valve 8, the cover plate 1 is provided with a fastener 13, and the bottom surface of the cover plate 1 is provided with a gasket layer 6. The feeding valve 8 is sealed and connected with the feeding nozzle 11 arranged on the cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com