Pressure test table for ribbon-tubular special radiator core

A radiator and tube-belt technology, which is applied in the direction of using liquid/vacuum for liquid tightness measurement, etc., can solve the problems of scrapping the radiator, affecting the sealing performance of the connection, etc., and achieves the effect of flexible assembly, simple structure and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

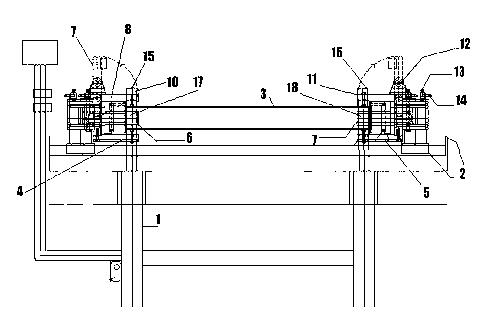

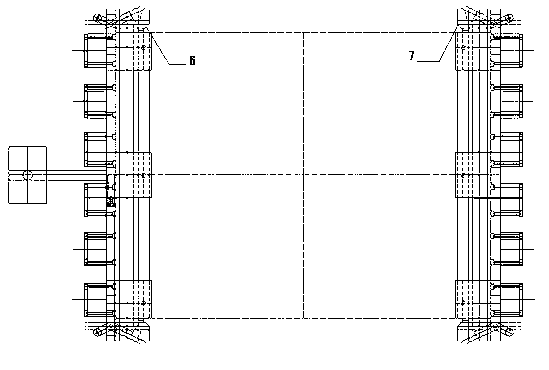

[0013] The present invention will be further described below in conjunction with accompanying drawing.

[0014] In the figure: guide rail frame 1, sliding guide rail assembly 2, pressure test core body 3, left mold support frame 4, right mold support frame 5, left movable hook 6, right movable hook 7, movable connection plate group 8, bracket Plate 9, left movable bracket 10, right movable bracket 11, movable pallet locator 12, air inlet and outlet adjustment switch 13, air pipe 14, left cylinder group 15 and right cylinder group 16 with pressure head of anti-loosening device, The left cylinder anti-loosening device 17, the right cylinder anti-loosening device 18, one side of the left cylinder group and the right cylinder group are equipped with a support plate, the left cylinder is assembled with an air inlet and outlet adjustment switch and an anti-loosening device, and the right cylinder is assembled with an inlet and outlet air adjustment switch Anti-loosening device, test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com