Film spool conveying system of plasma etcher

A plasma and etching machine technology, applied in the field of film transfer system, can solve the problems of low degree of automation and small disk throughput, and achieve the effect of high degree of automation, high production efficiency, and adapting to the needs of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

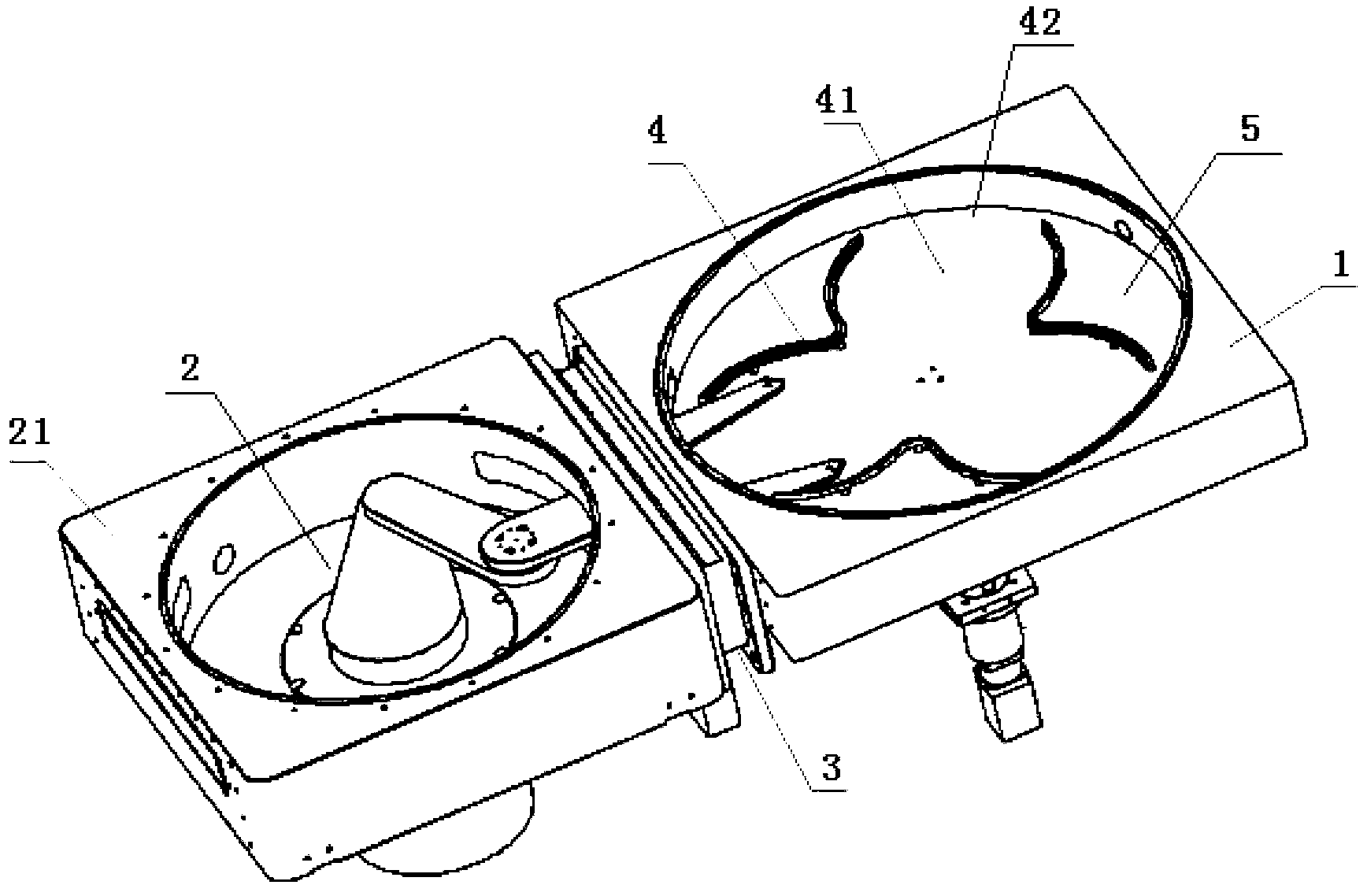

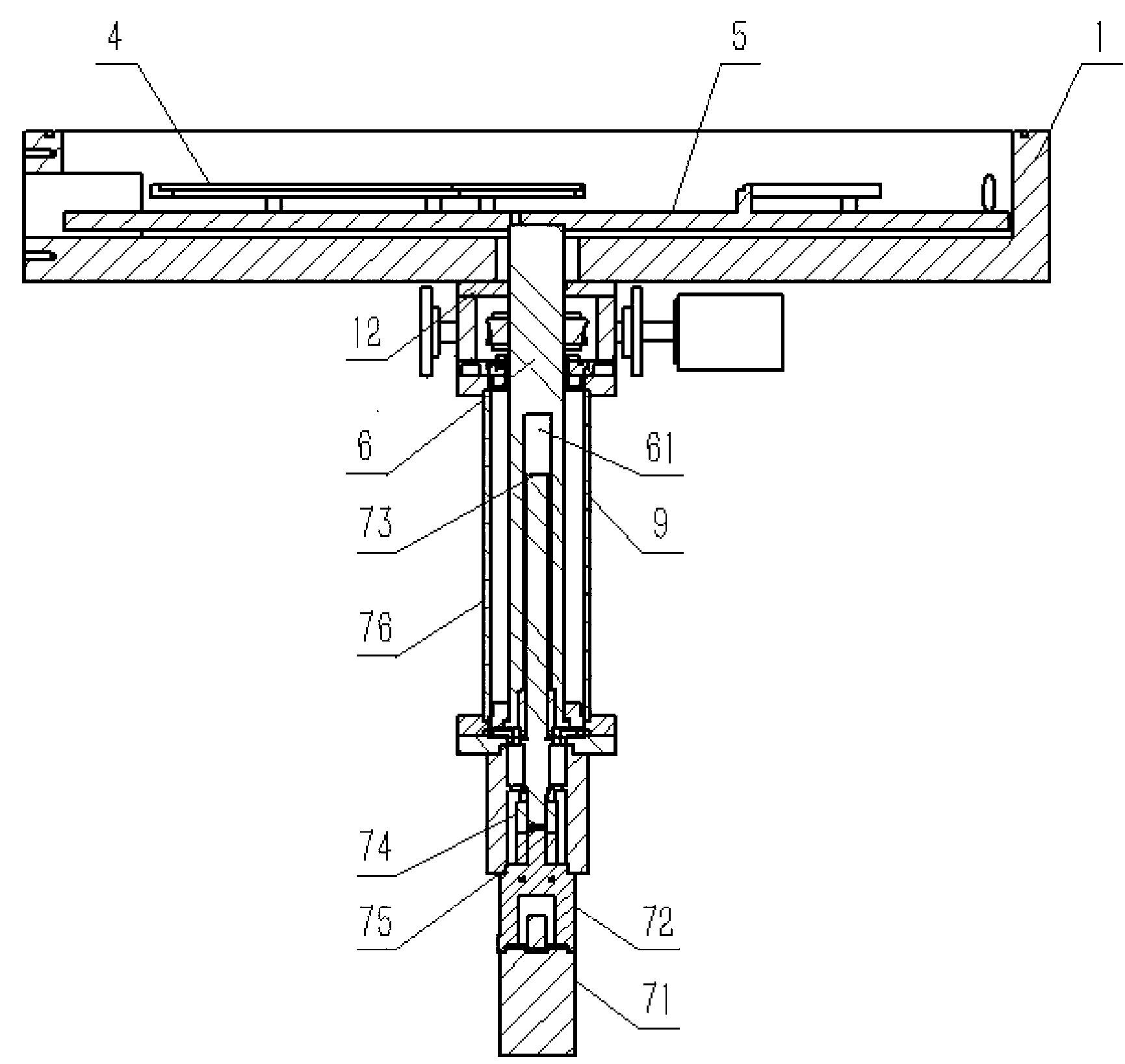

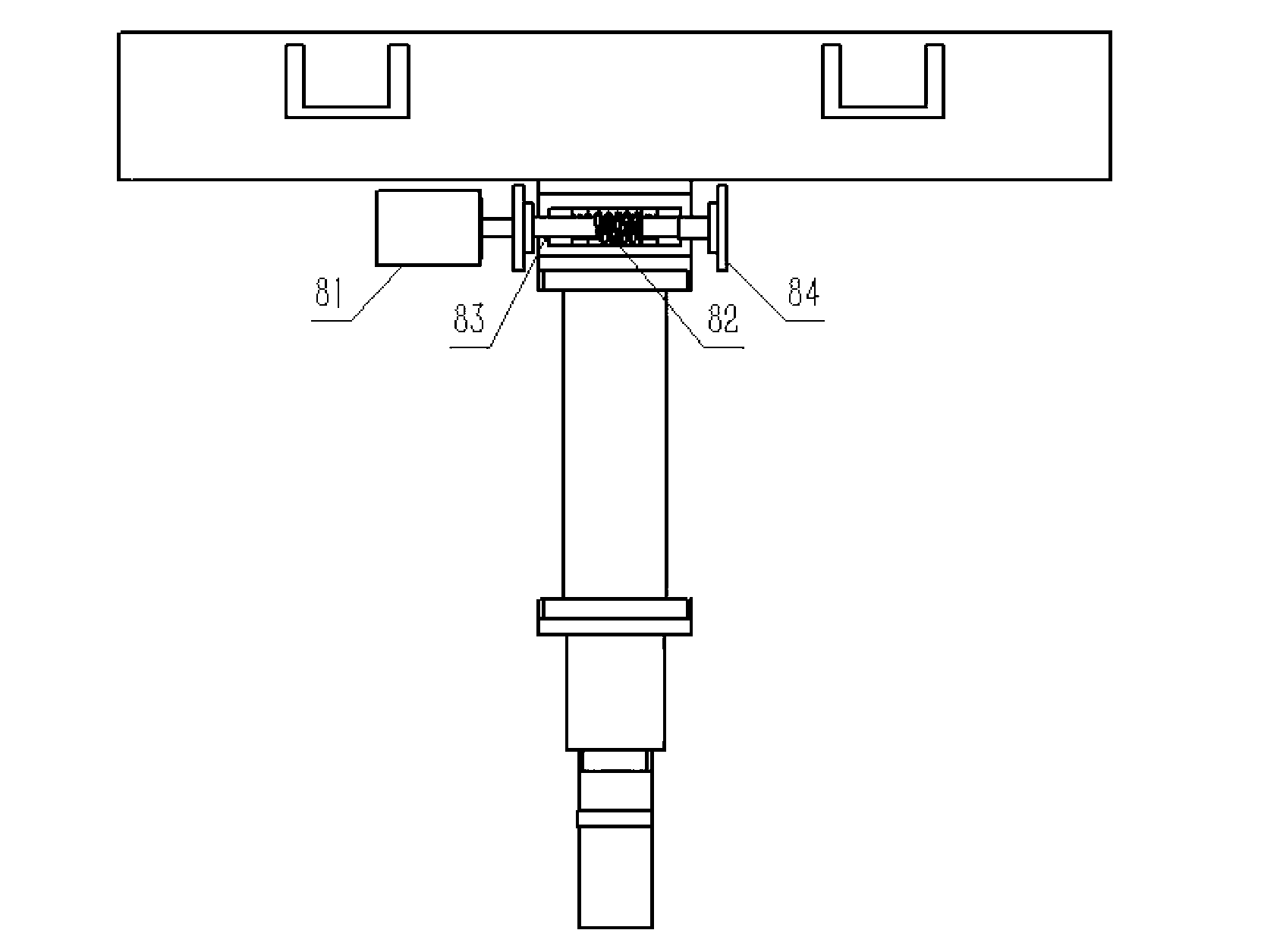

[0024] A film transfer system of a plasma etching machine, consisting of a loading device and a manipulator device;

[0025] The loading device includes a loading chamber 1 and a chamber cover 1A, a sealing ring is provided between the loading chamber 1 and the chamber cover 1A, a side of the loading chamber 1 is provided with a feeding port, and a plug valve 3 is provided at the feeding port; The loading cavity 1 is connected with the vacuum mechanical pump and the external air source;

[0026] The manipulator device includes a manipulator 2 and a housing chamber 21 of the manipulator 2, the housing chamber 21 communicates with the loading chamber 1 through the flapper valve 3, and the manipulator 2 enters the loading chamber 1 through the feeding port;

[0027] The inside of the loading cavity 1 is provided with a tray rack 4 for supporting the discs. The tray rack 4 has a plurality of supporting positions 41 for supporting the discs. Each supporting position 41 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com