Branch cantilever beam vibration generator and power generation method thereof

A technology of vibrating generators and cantilever beams, applied in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve problems such as difficulties in power management and improve frequency response characteristics , Improve the effect of frequency domain response characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

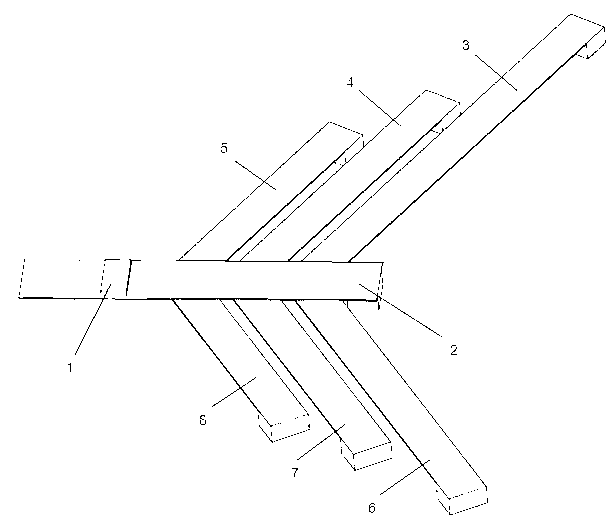

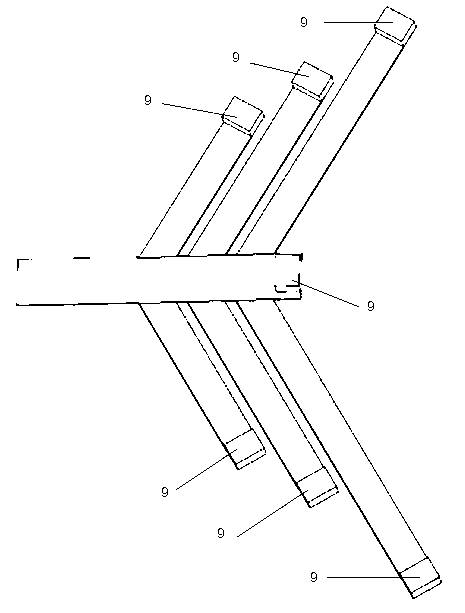

[0022] please combine Figure 1 to Figure 2 As shown, the bifurcated cantilever beam vibration generator of the present invention includes a cantilever beam 2, a first bifurcation 3, a second bifurcation 4, a third bifurcation 5, a fourth bifurcation 6, a fifth bifurcation 7, a Six bifurcations 8, the piezoelectric element 1 arranged (pasted) at the root of the cantilever beam 2 and the counterweight 9 arranged (pasted) at the ends of the foregoing bifurcations 3, 4, 5, 6, 7, 8 and the cantilever beam 2 . The number of middle forks of the bifurcated cantilever beam vibration generator is at least one, and the foregoing bifurcations 3, 4, 5, 6, 7, and 8 can be arranged on one side or both sides of the cantilever beam, and the bifurcations 3, 4, 5, 6, 7, 8 can be placed symmetrically or asymmetrically. At the same time, the positions of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com