Glass composition for producing high strength and high modulus fibers

A composition, high-strength technology, applied in glass manufacturing equipment, fabrics, wind turbines in the same direction as the wind, etc., can solve problems such as large corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

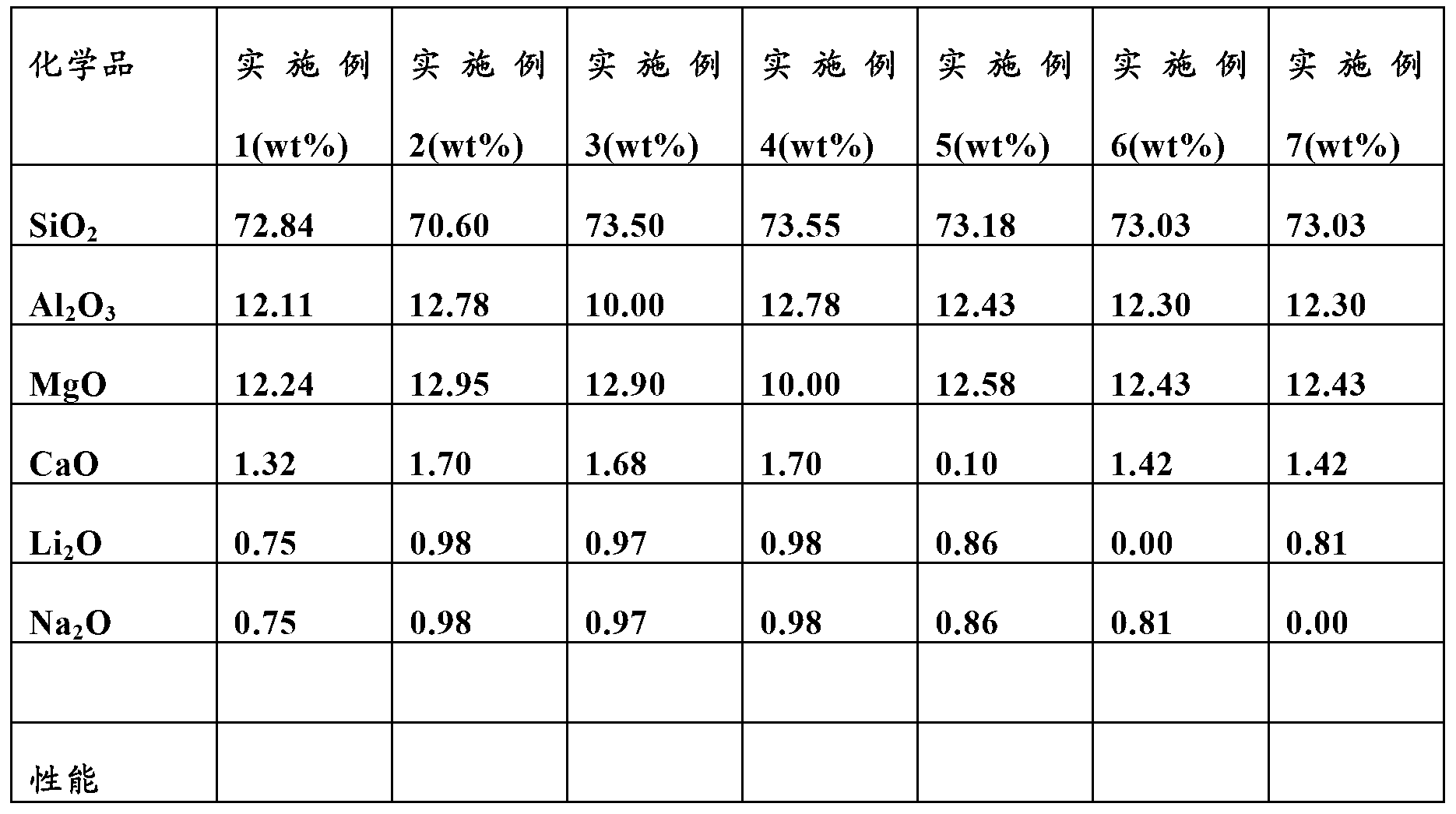

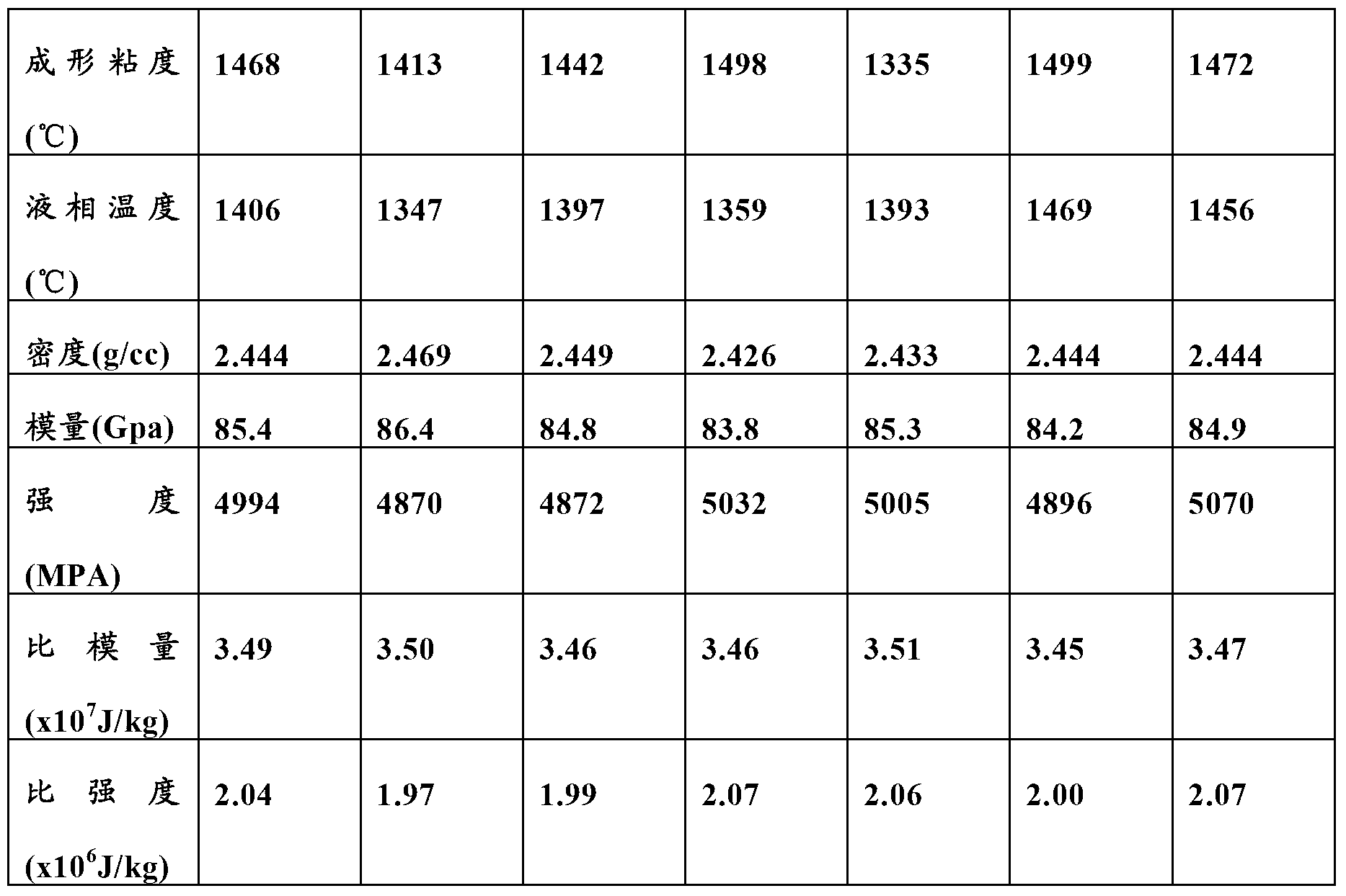

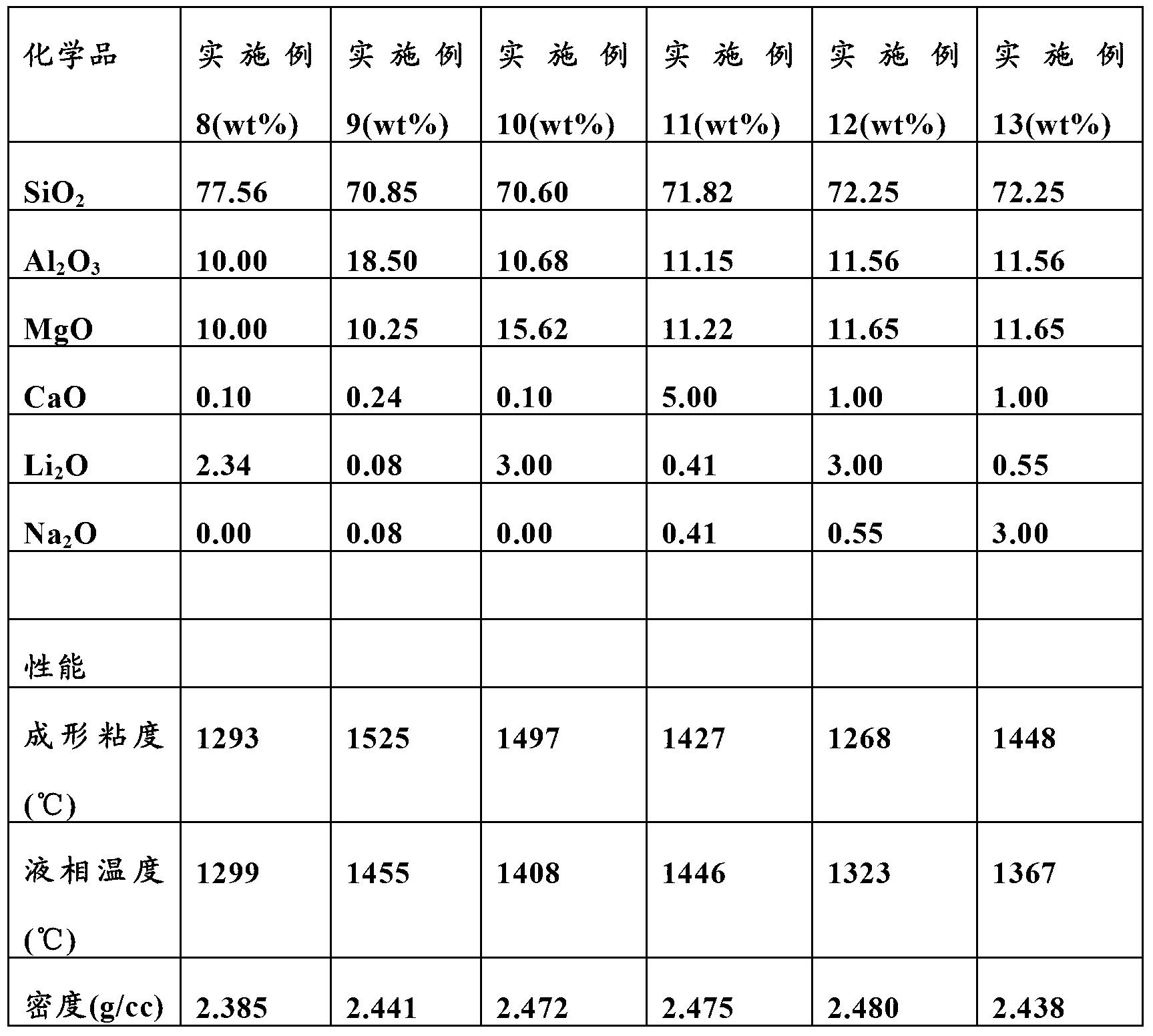

[0057] Example 1: High Performance Glass Composition

[0058] Glass compositions of the present invention were made by mixing reagent grade chemicals in amounts to achieve the final glass composition formulation having the oxide weight percents listed in Tables 6 and 7. The starting materials were melted in platinum crucibles at a temperature of 1650° C. for 3 hours in an electrically heated furnace. The forming viscosity (ie, the temperature corresponding to a viscosity of about 1000 poise) was measured using the rotating cylinder method (ASTM C965-96 (2007)). The liquidus temperature was measured by exposing the glass to a temperature gradient in a platinum-alloy boat for 16 hours (ASTM C829-81 (2005)). Density was measured by the Archimedes method (ASTM C693-93(2008)). To manufacture the glass fibers used for testing modulus and strength, cullet from the glass composition was added to the resistance bushing and pulled from a single tip at the bottom of the bushing. The f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com